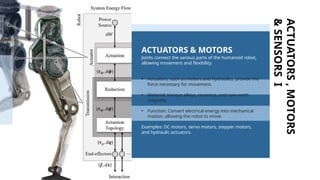

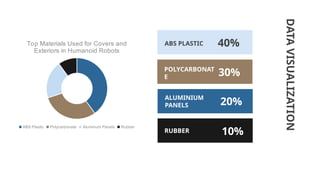

The document provides an overview of humanoid robots, detailing their components, materials used in construction, and applications. It emphasizes the importance of engineering materials for functionality and performance, discusses standard components like actuators and sensors, and presents a case study on Boston Dynamics' Atlas robot. Future developments and challenges in the field are also highlighted, focusing on advancements in materials science and robot capabilities.