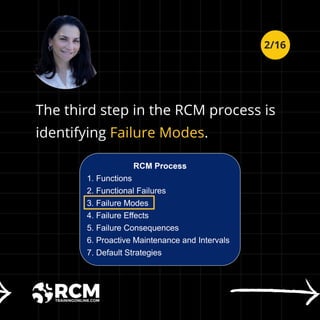

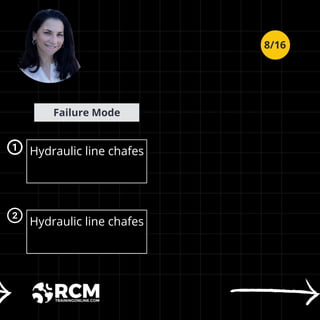

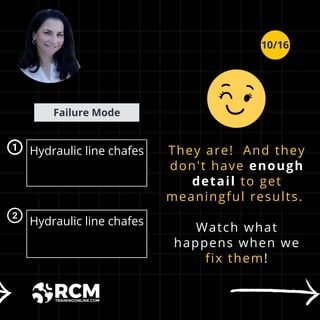

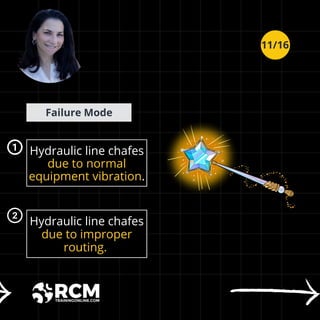

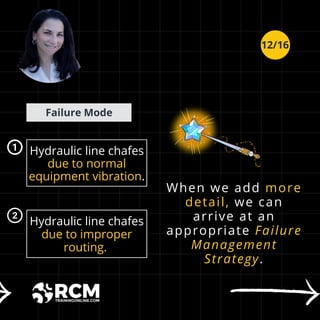

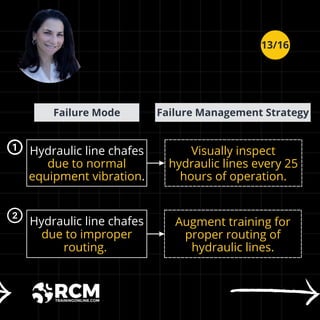

The document emphasizes the importance of properly identifying failure modes in the Reliability-Centered Maintenance (RCM) process, which is crucial for managing physical assets. It highlights that vague or overly detailed descriptions can lead to ineffective results and analysis paralysis. The author advocates for writing failure modes at the right level of detail to facilitate effective failure management strategies.