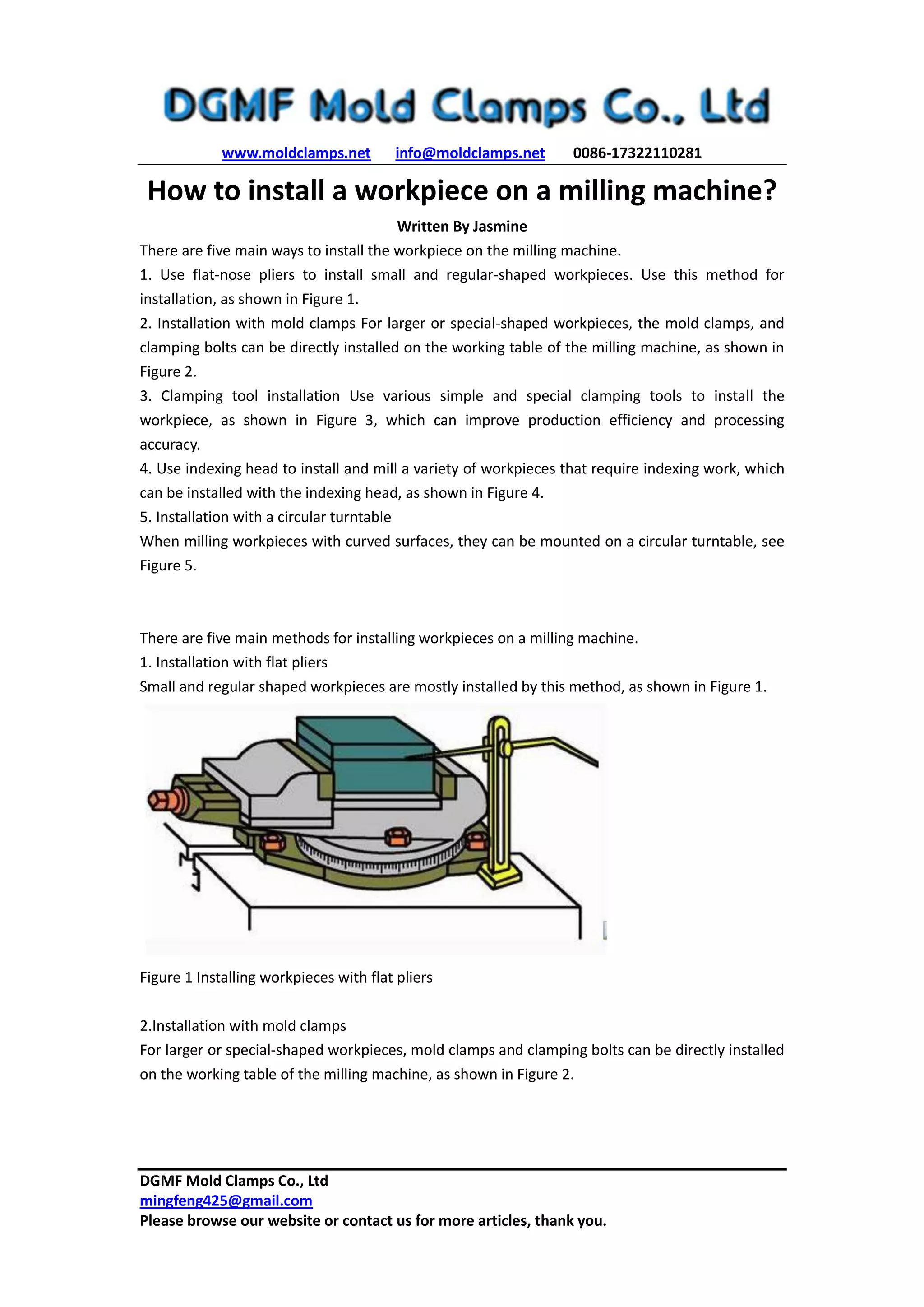

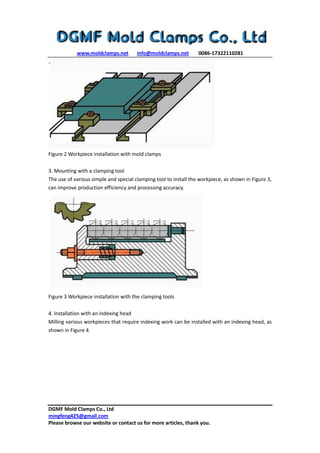

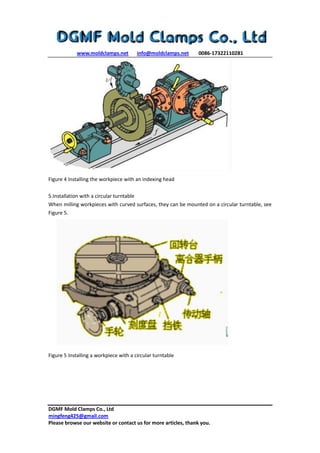

There are five main methods for installing workpieces on a milling machine: 1) Using flat-nose pliers for small, regular shapes; 2) Mold clamps and bolts for larger or irregular shapes; 3) Clamping tools to improve efficiency and accuracy; 4) Indexing heads for work requiring indexing; and 5) Circular turntables for curved surfaces. Details and diagrams are provided for each installation method.