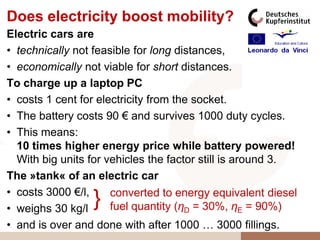

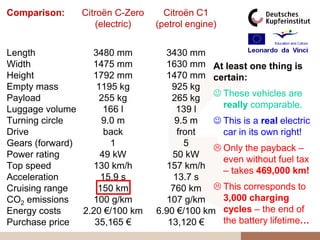

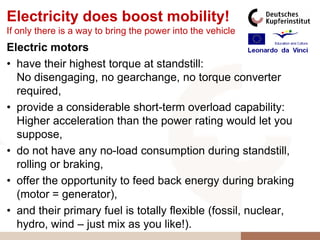

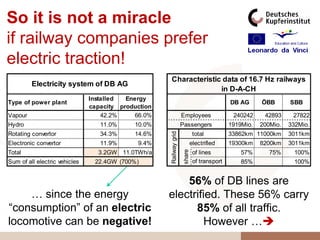

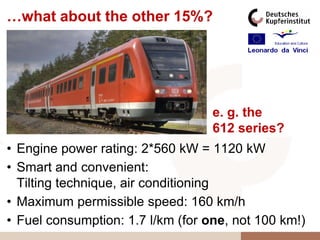

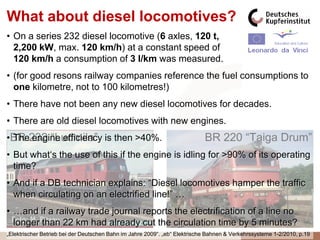

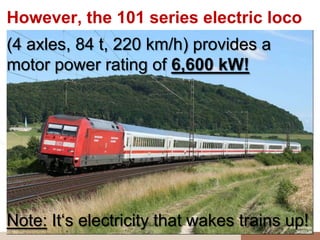

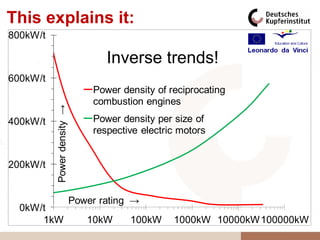

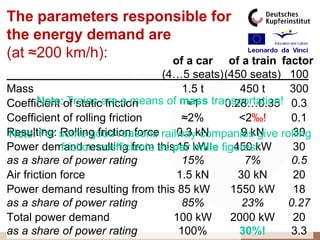

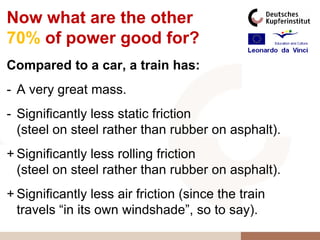

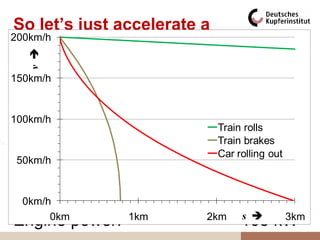

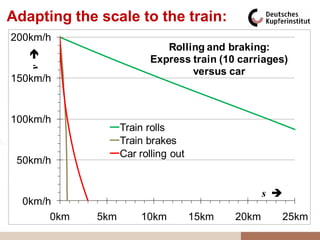

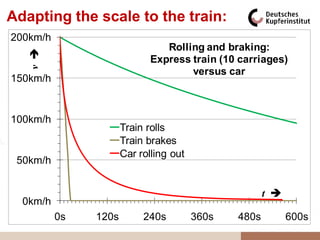

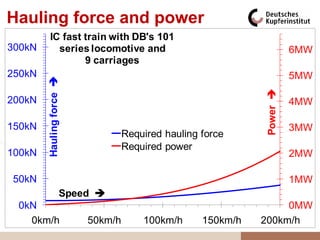

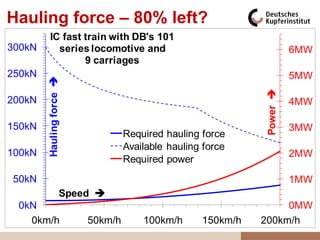

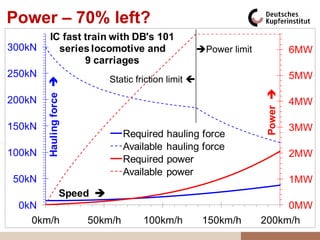

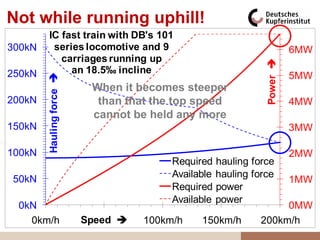

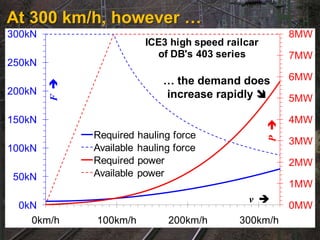

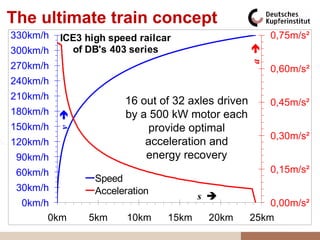

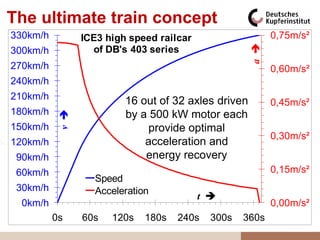

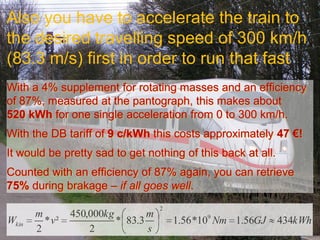

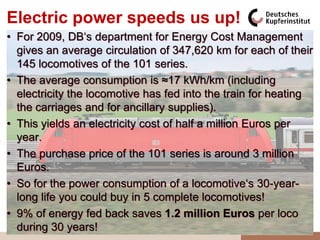

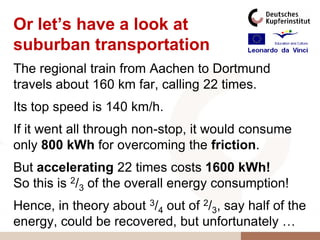

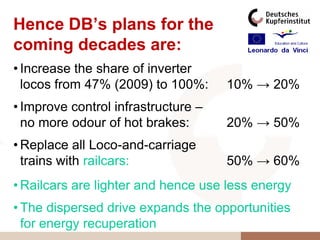

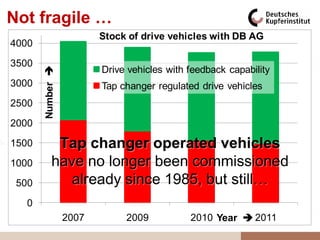

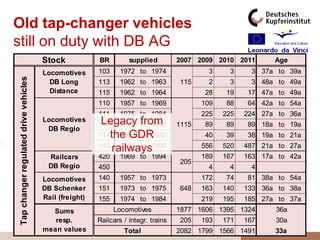

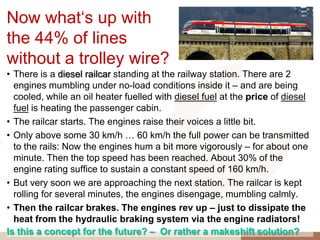

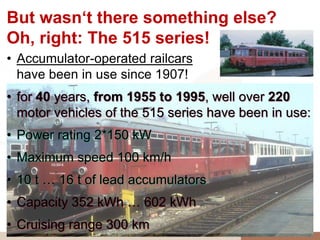

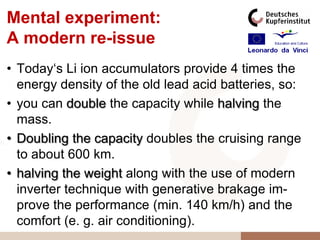

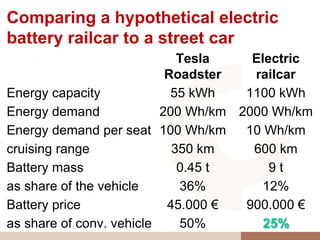

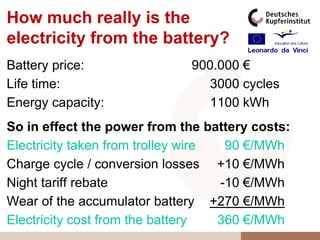

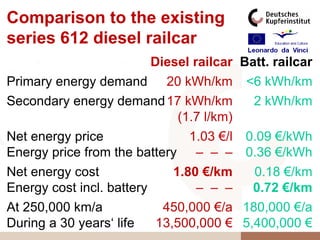

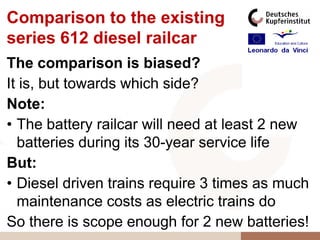

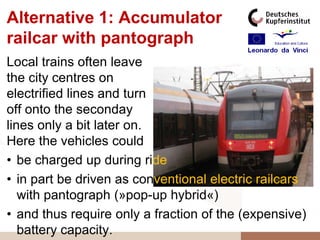

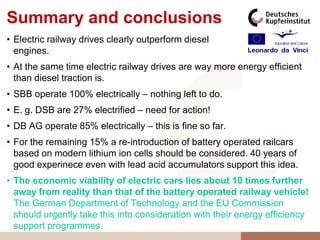

The document evaluates the energy efficiency of railway transportation compared to electric and diesel vehicles, highlighting the advantages of electric traction in terms of energy recovery and reduced power demand. It provides a detailed comparison of electric and diesel locomotives, emphasizing the superior performance and efficiency of electric trains. Moreover, it points out the significant potential for energy savings and environmental benefits through the increased electrification of railway lines.