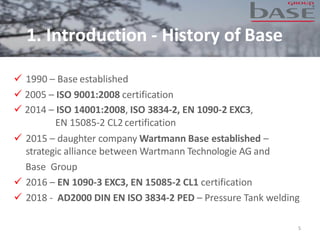

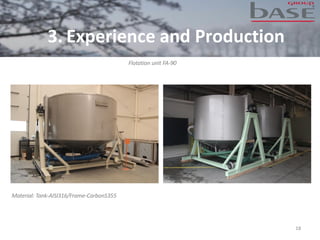

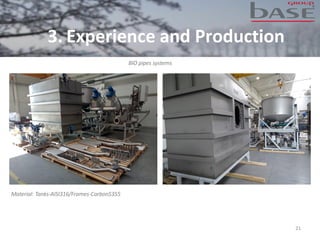

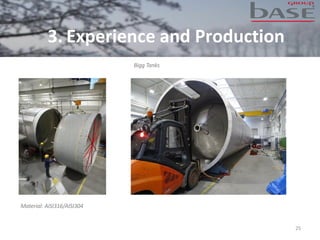

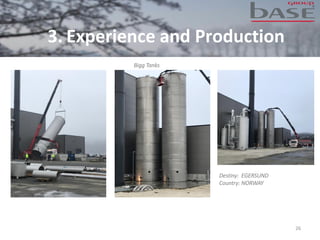

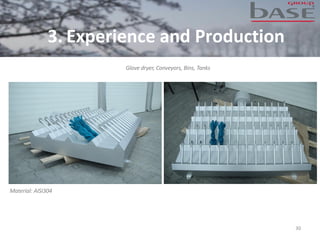

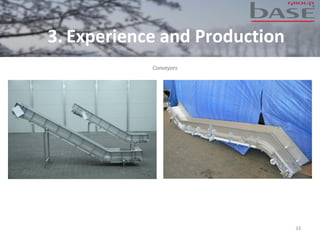

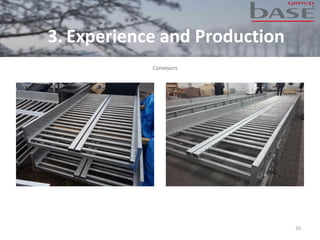

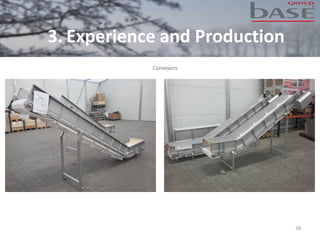

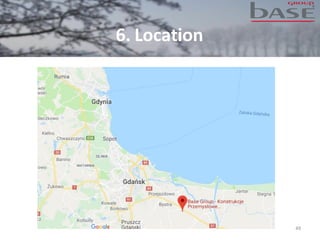

Base is a metal manufacturing company with over 27 years of experience, specializing in welding, machining, and surface treatment of various metals. The company is certified under multiple quality and environmental standards and operates from a strategically located facility in Poland. They cater to diverse industries including energy, marine, and oil & gas, employing a skilled team to deliver high-quality services.