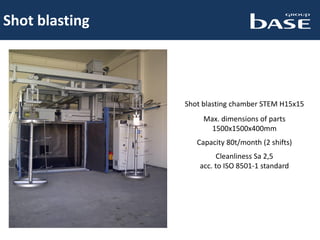

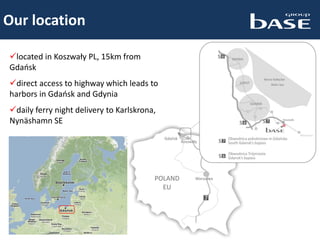

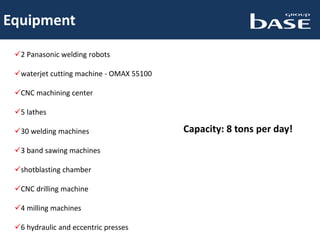

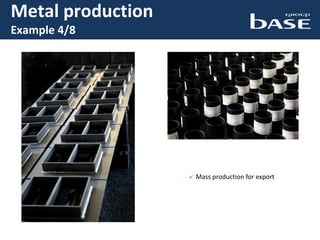

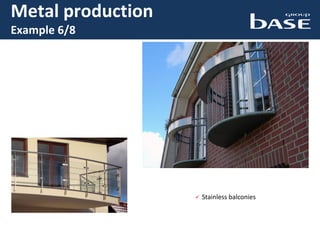

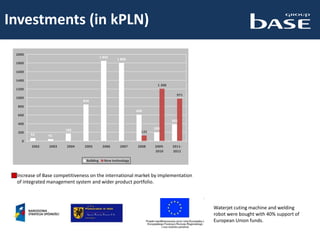

Base Group is a Polish metal fabrication company located near Gdansk that specializes in welding, metal manufacturing, waterjet cutting, blasting, and bending of steel, stainless steel, and aluminum. It has over 130 employees, modern equipment like welding robots and a waterjet cutting machine, and provides prefabrication and assembly services for structures and equipment used in construction, offshore, and other industries. It aims to increase its competitiveness on international markets through quality certifications and expanded product offerings.