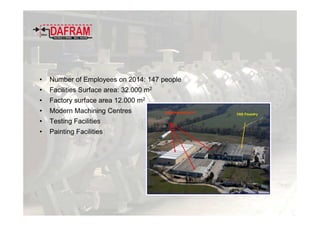

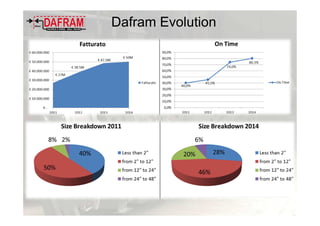

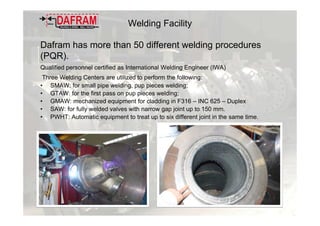

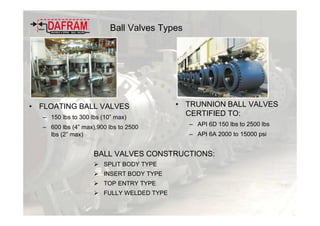

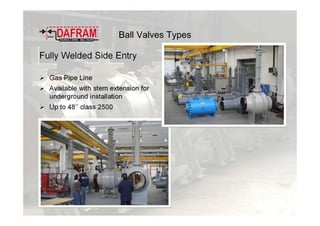

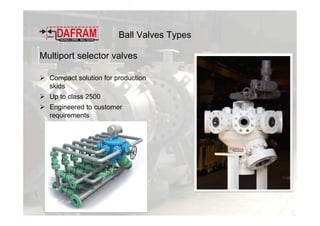

Dafram SpA is an Italian manufacturer of ball valves and other forged and cast metal components established in 1956. It employs 147 people across 32,000 square meters of facilities, including a 12,000 square meter factory. Dafram specializes in custom manufacturing according to client specifications across industries like oil and gas. It holds various international certifications and has approval from major companies in the industry. Production has increased annually in recent years across various valve sizes up to 48 inches. Dafram utilizes modern machining centers and testing facilities and sources raw materials from Western European suppliers.