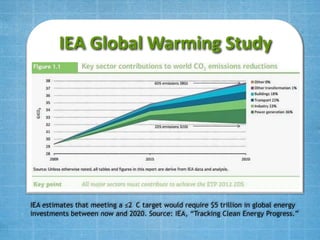

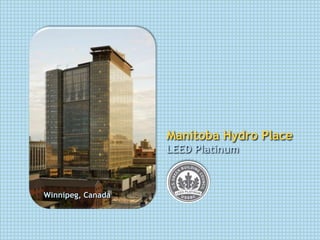

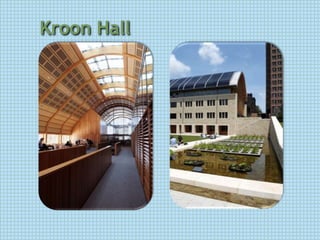

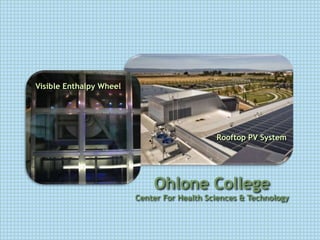

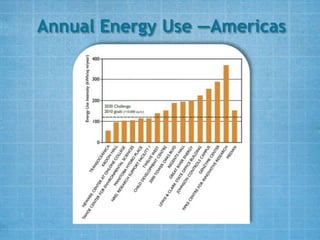

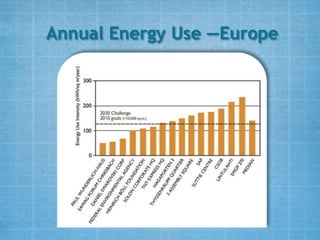

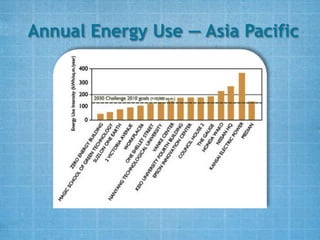

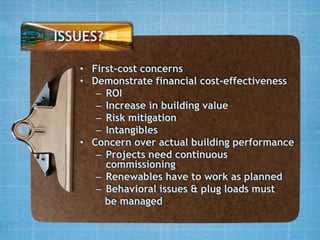

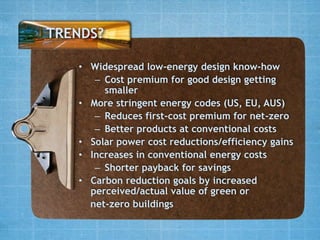

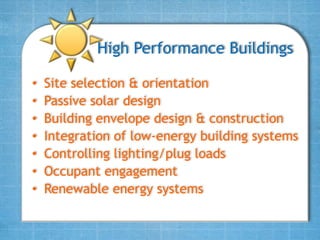

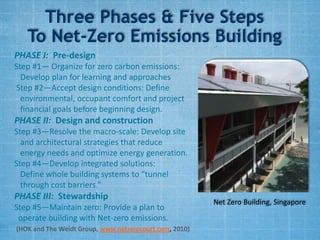

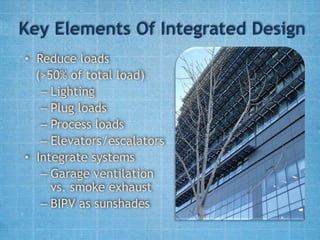

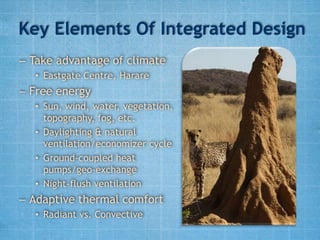

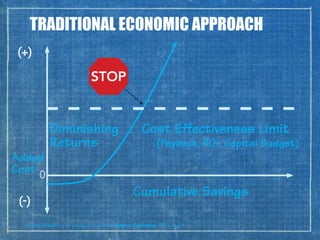

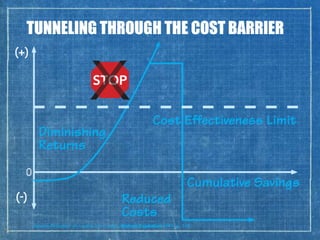

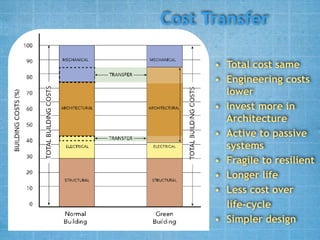

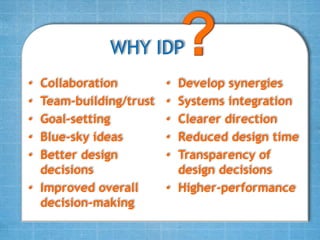

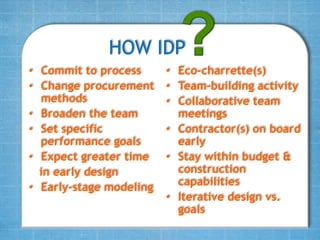

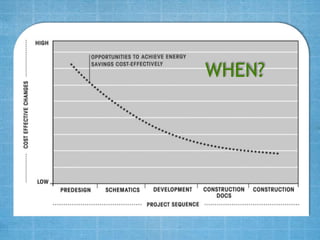

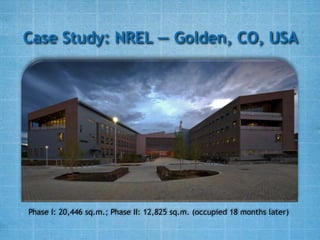

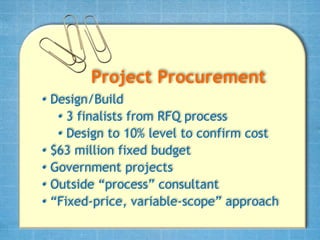

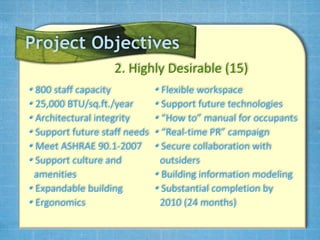

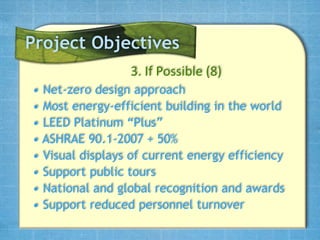

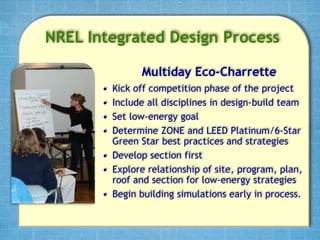

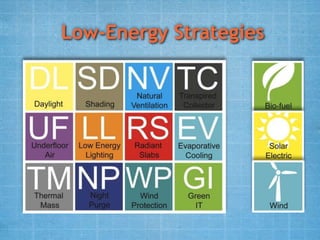

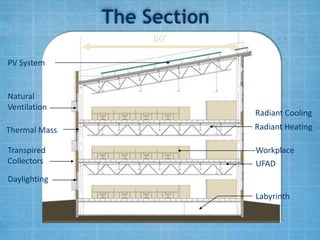

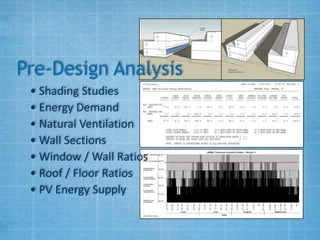

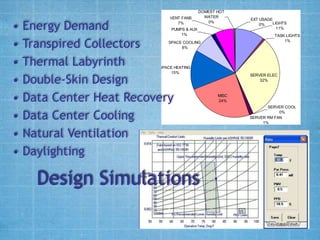

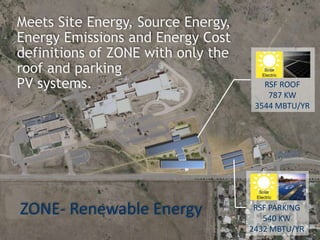

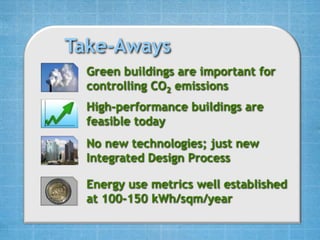

The document discusses high-performance building design, emphasizing the importance of green buildings in reducing CO2 emissions and presenting case studies of LEED Platinum projects. It outlines an integrated design process for achieving net-zero emissions, highlighting key strategies such as site selection, passive solar design, and occupant engagement. Additionally, it addresses common concerns like first-cost barriers and the need for continuous performance monitoring to ensure successful energy and efficiency outcomes.