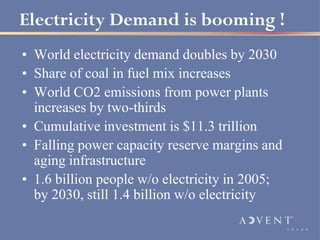

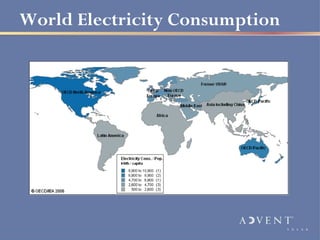

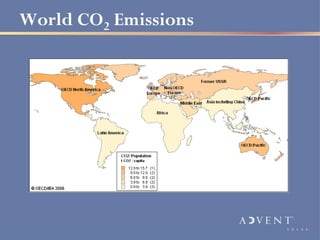

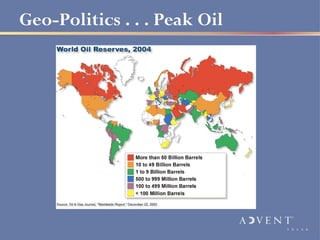

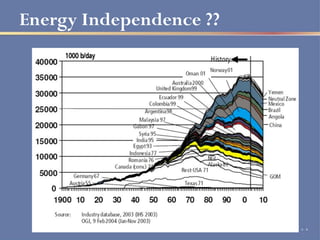

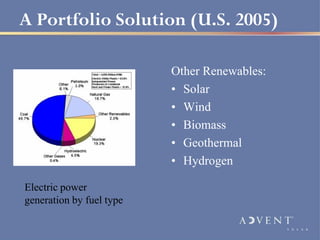

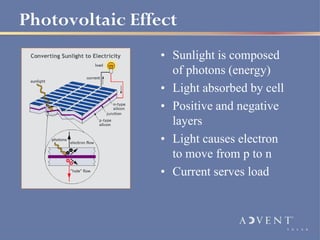

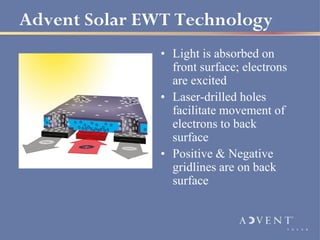

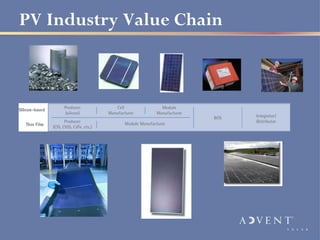

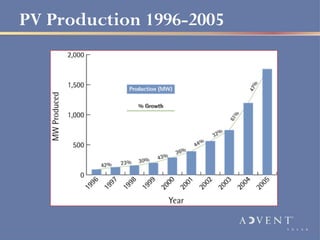

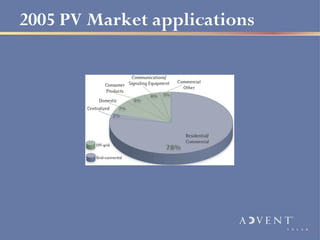

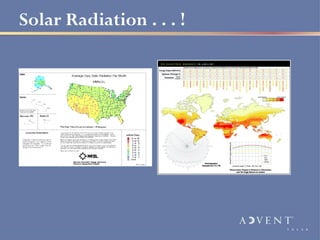

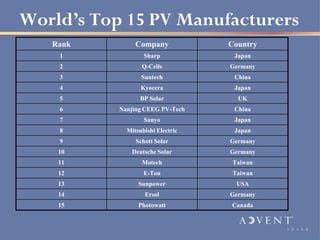

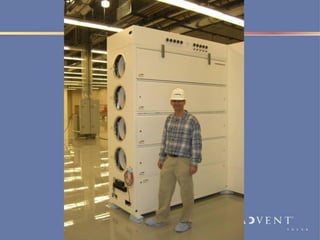

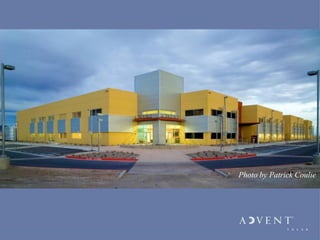

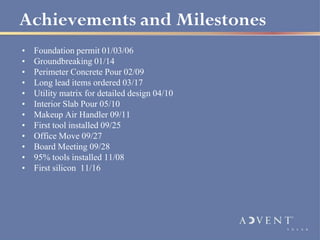

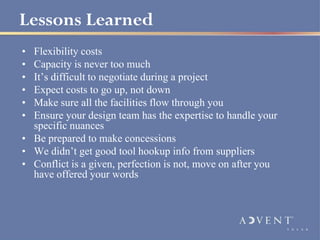

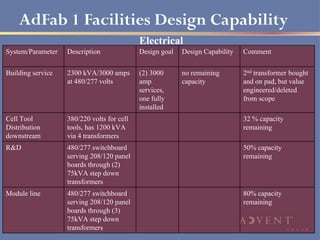

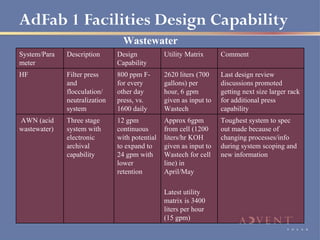

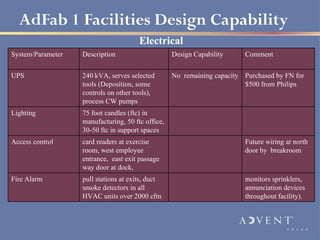

The document summarizes a presentation on solar energy given to the New Mexico Association of Facilities Managers. It discusses trends in global energy demand and supply, the advantages of solar power technologies like photovoltaics, and provides an overview of Advent Solar, a startup company that established a pilot solar cell production line in New Mexico.