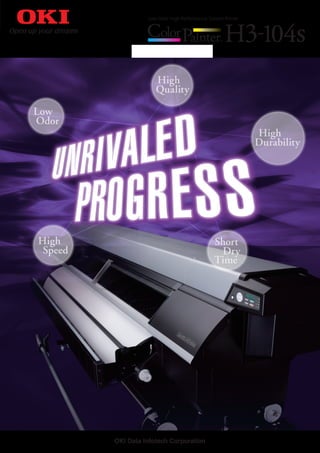

The ColorPainter H3-104S is a high-performance, eco-friendly solvent printer that offers low odor, high speed printing, and excellent outdoor durability. It features advanced technologies such as dynamic dot printing, automated media adjustments, and a robust ink system allowing for continuous high-volume printing. With a user-friendly software interface, this printer meets the demands of sign and graphics professionals by delivering quality results quickly and efficiently.