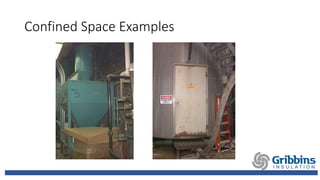

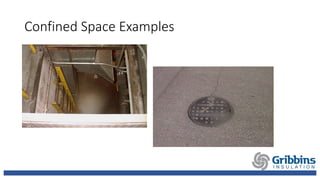

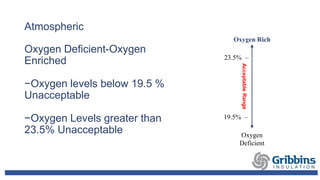

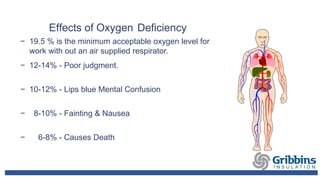

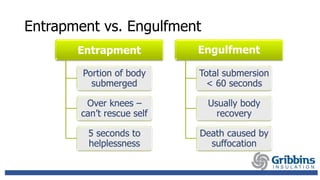

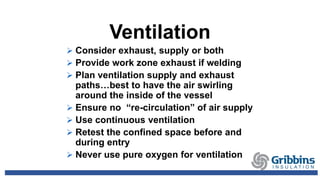

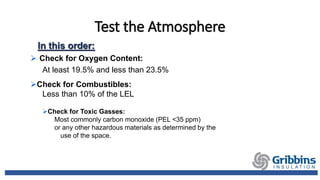

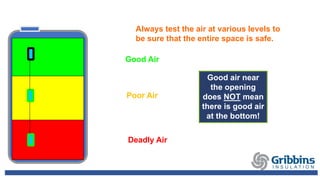

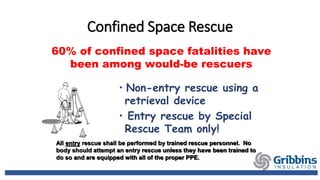

This document provides an overview of confined space safety training. It defines what constitutes a confined space and permit-required confined space. It identifies several common hazards within confined spaces including atmospheric hazards like oxygen deficiency, flammable or toxic gases, and engulfment hazards. The document outlines the basic confined space entry procedure and roles of the entry supervisor and attendant. It discusses atmospheric monitoring, ventilation, rescue procedures, and PPE requirements for confined space work.