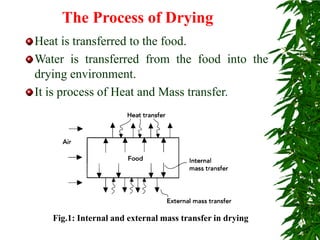

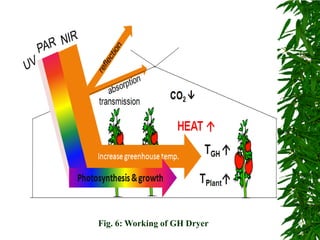

This document discusses greenhouse drying techniques for preserving agricultural produce. It begins by explaining that drying is one of the oldest food preservation methods by removing moisture from foods to prevent spoilage. It then covers various drying methods like open sun drying, greenhouse drying, passive and active solar drying, direct and indirect solar drying, and mixed-mode drying. It also discusses factors that affect the drying process and advantages and disadvantages of different techniques. Finally, it proposes a low-cost multipurpose greenhouse that can be used for both crop cultivation and drying of produce during different seasons for improved utilization and farmer livelihoods.