The document discusses the design of 90 gravity-based foundations for the Rødsand 2 offshore wind farm in Denmark. Key details include: the foundations used pre-fabricated reinforced concrete caissons with octagonal bases and cylindrical shafts; soil conditions included clay till and required re-evaluation to increase the undrained shear strength for design; bearing capacity was evaluated using 2D plane strain analyses and 3D Abaqus modeling to handle complex soil profiles and load combinations. The design was performed under a tight schedule through integrated constructability and optimized foundation geometry for each location.

![#

Ground conditions and geotechnical investigations

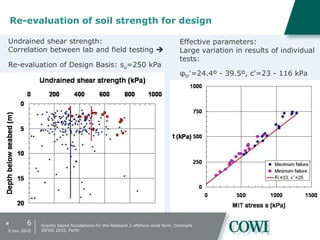

Owner's Design Basis: Danish Clay till, su=200 kPa

Original ground investigation (2007):

• 183 CPTs to a depth of 2.9 ± 2.4 m;

86 nos. outside footprints

• 80 geotechnical boreholes;

majority to a depth of 7 m

• 200 UU tests; in lieu of field vane testing

• 16 valid triaxial CAU tests

Supplementary ground investigations by Contractor

(2009):

• 31 geotechnical boreholes with SPT

to a depth of 15-20 m

• 6 triaxial CAU tests and oedometer tests

Need for confirmation

of strength at depths!

5

9 nov 2010

Gravity based foundations for the Rødsand 2 offshore wind farm, Denmark

ISFOG 2010, Perth

Row 2

-12

-10

-8

-6

0 500 1000 1500

cu [kPa]

Level

[m]

Su [kPa]](https://image.slidesharecdn.com/lyngsgravitybasedfoundationsfortherdsand2offshore2010-f-130720052217-phpapp02/85/Gravity-based-foundations-for-the-Rodsand-2-offshore-wind-farm-Denmark-5-320.jpg)