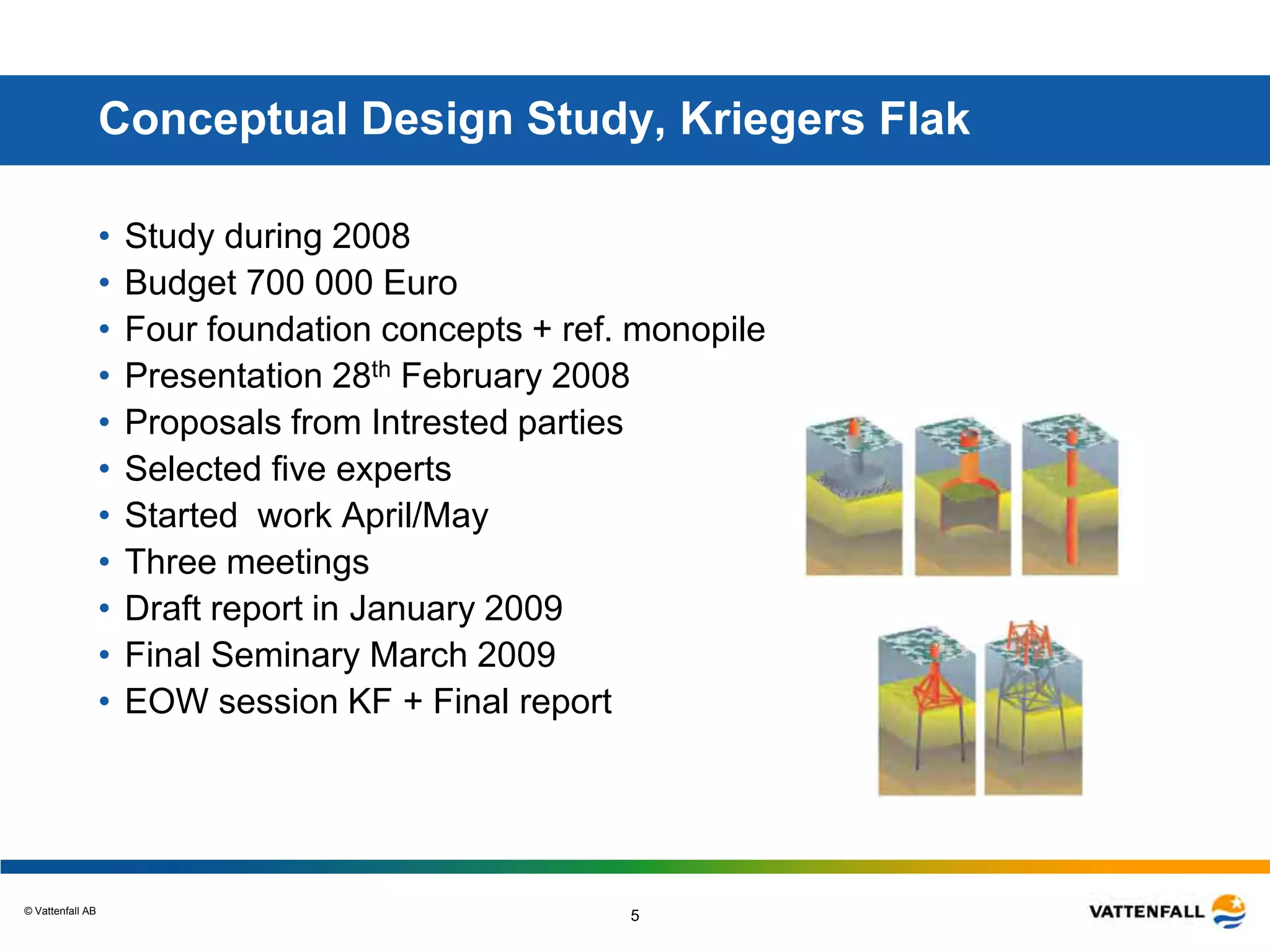

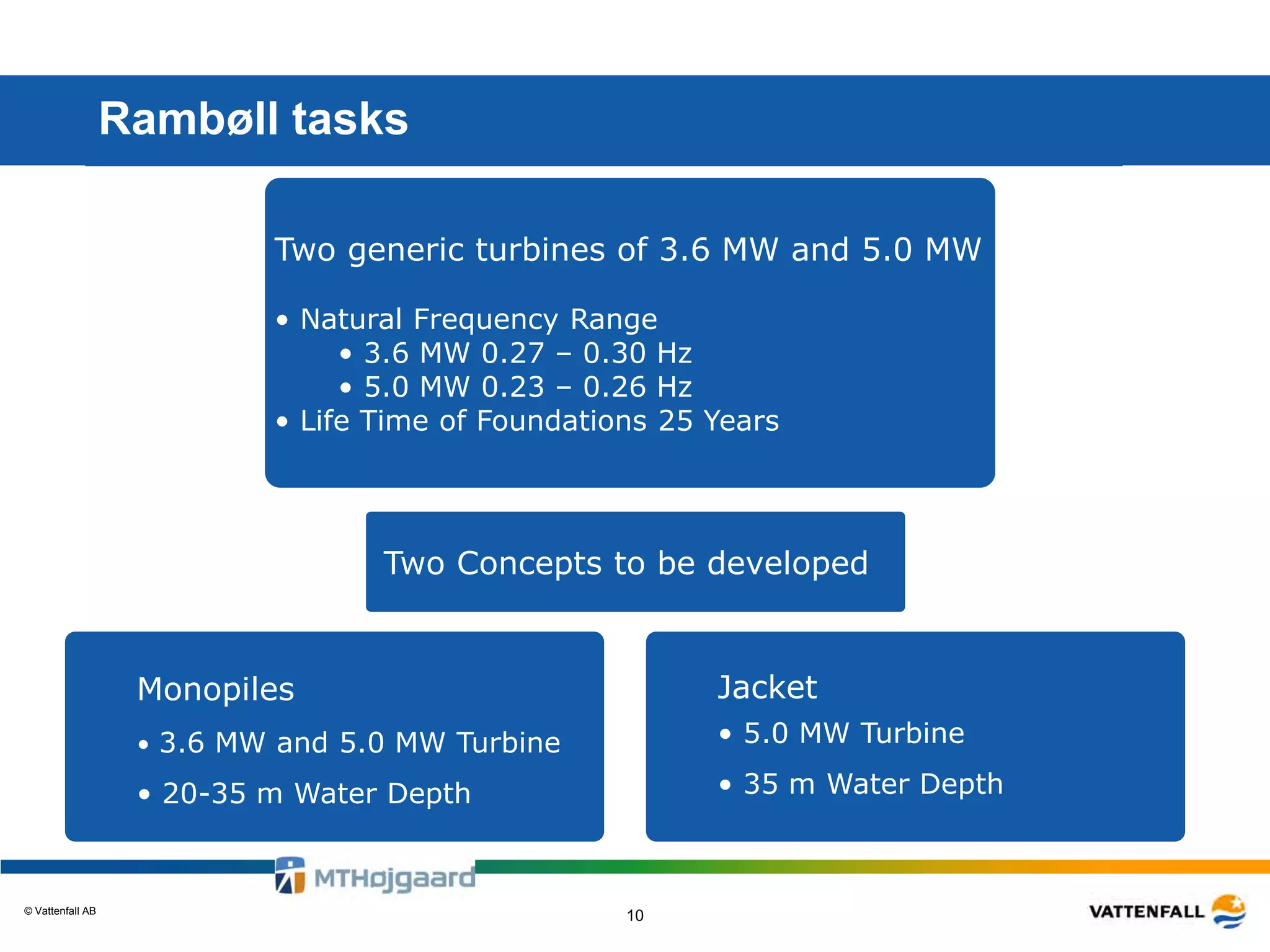

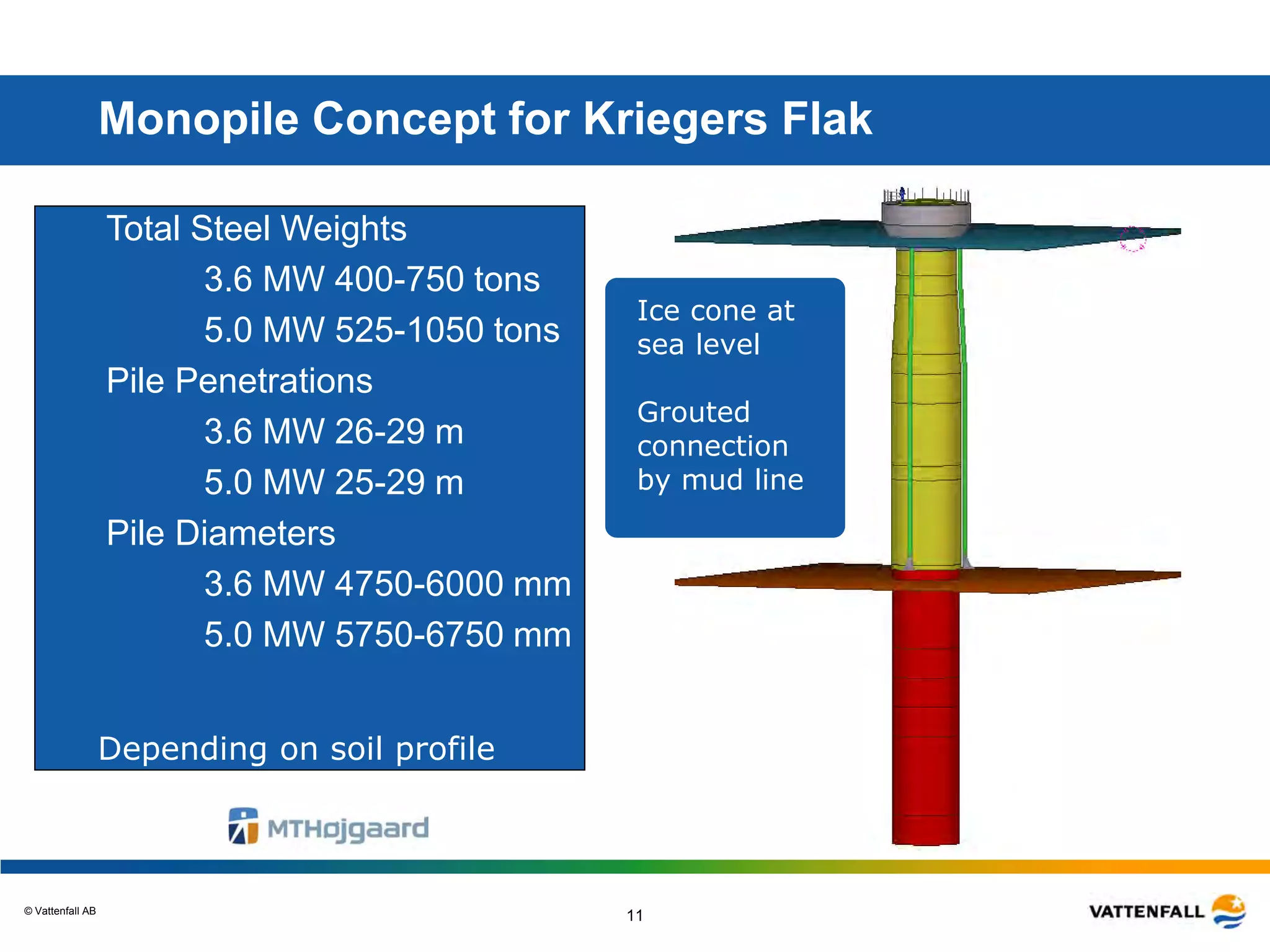

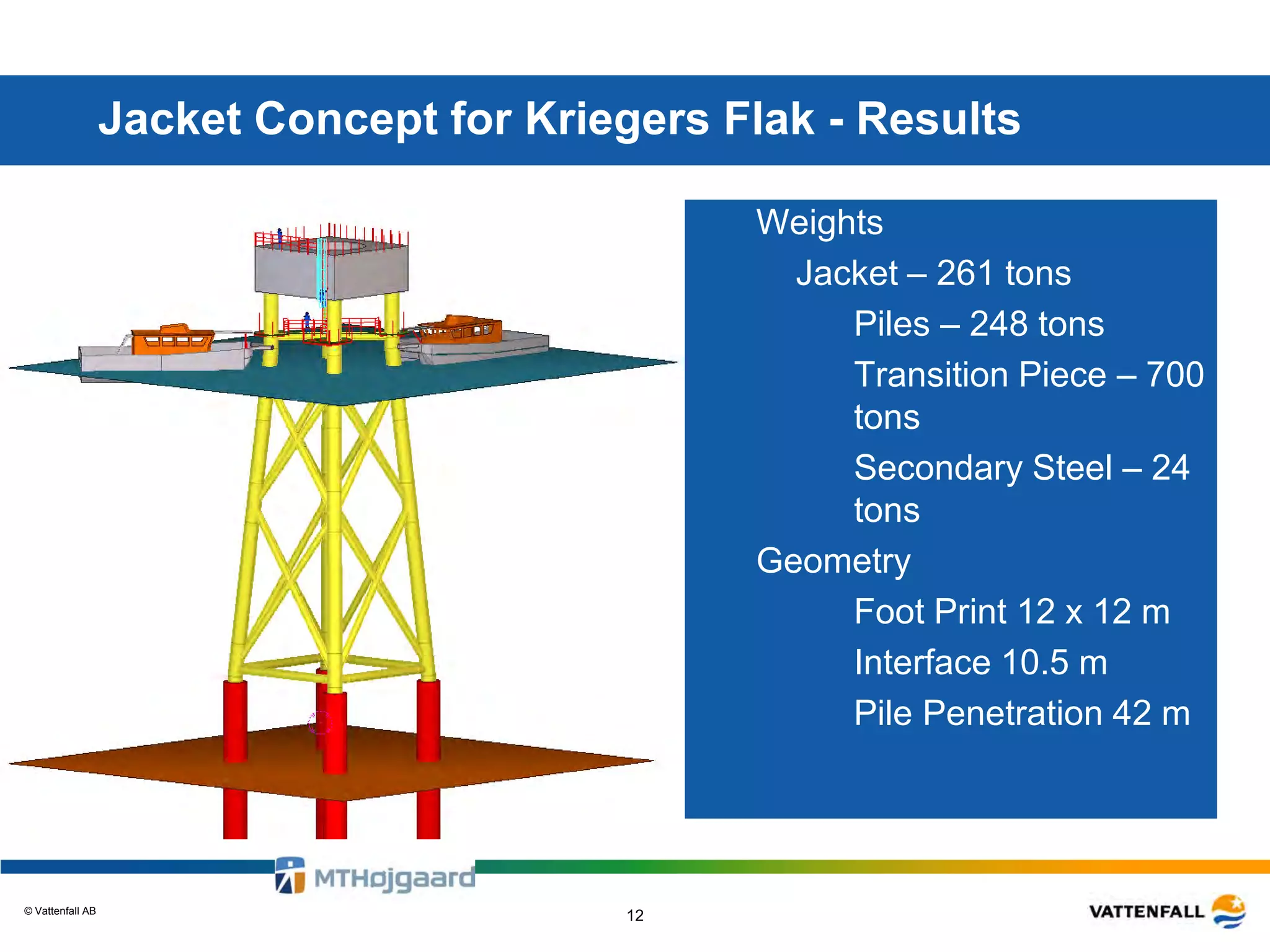

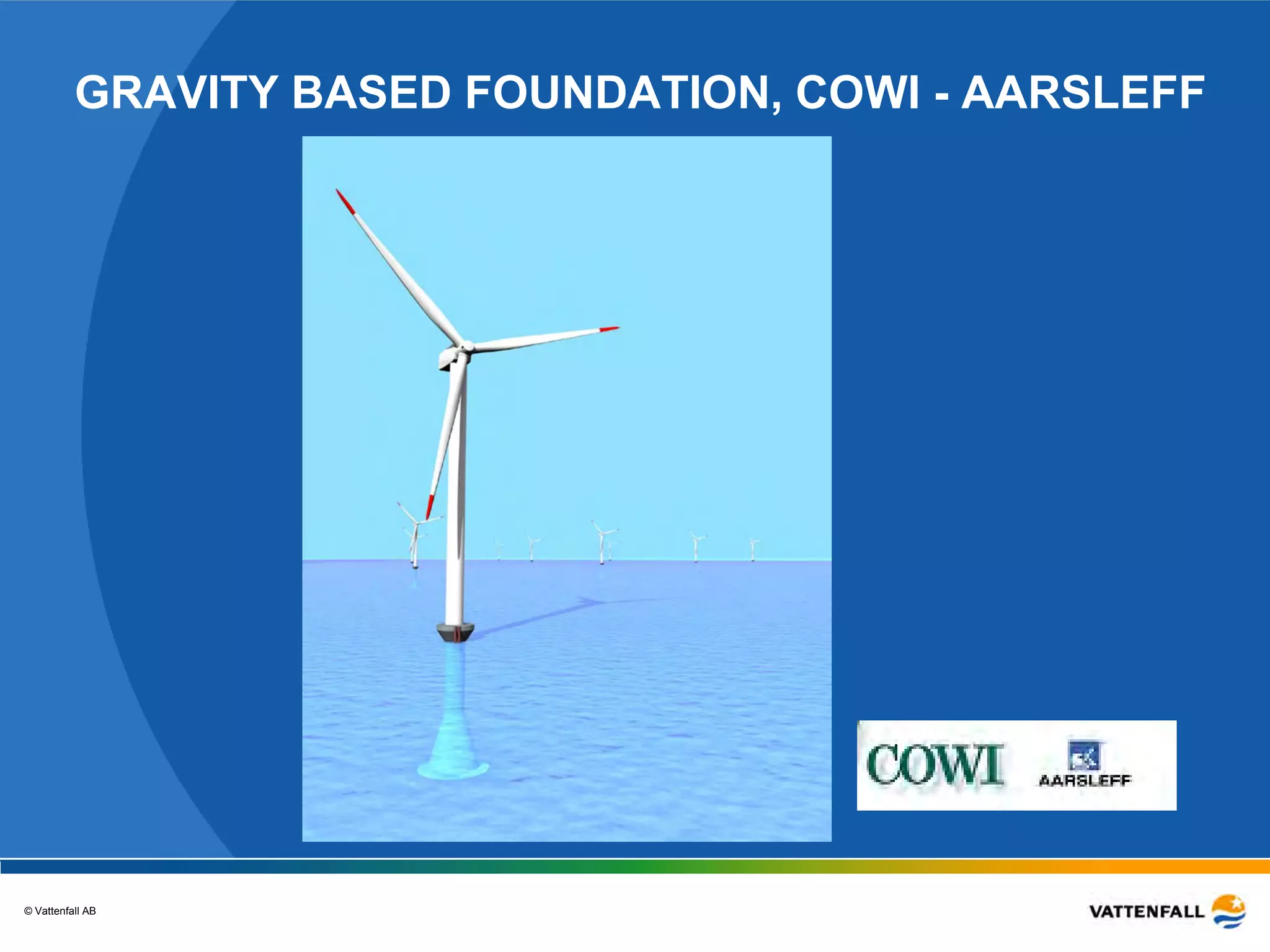

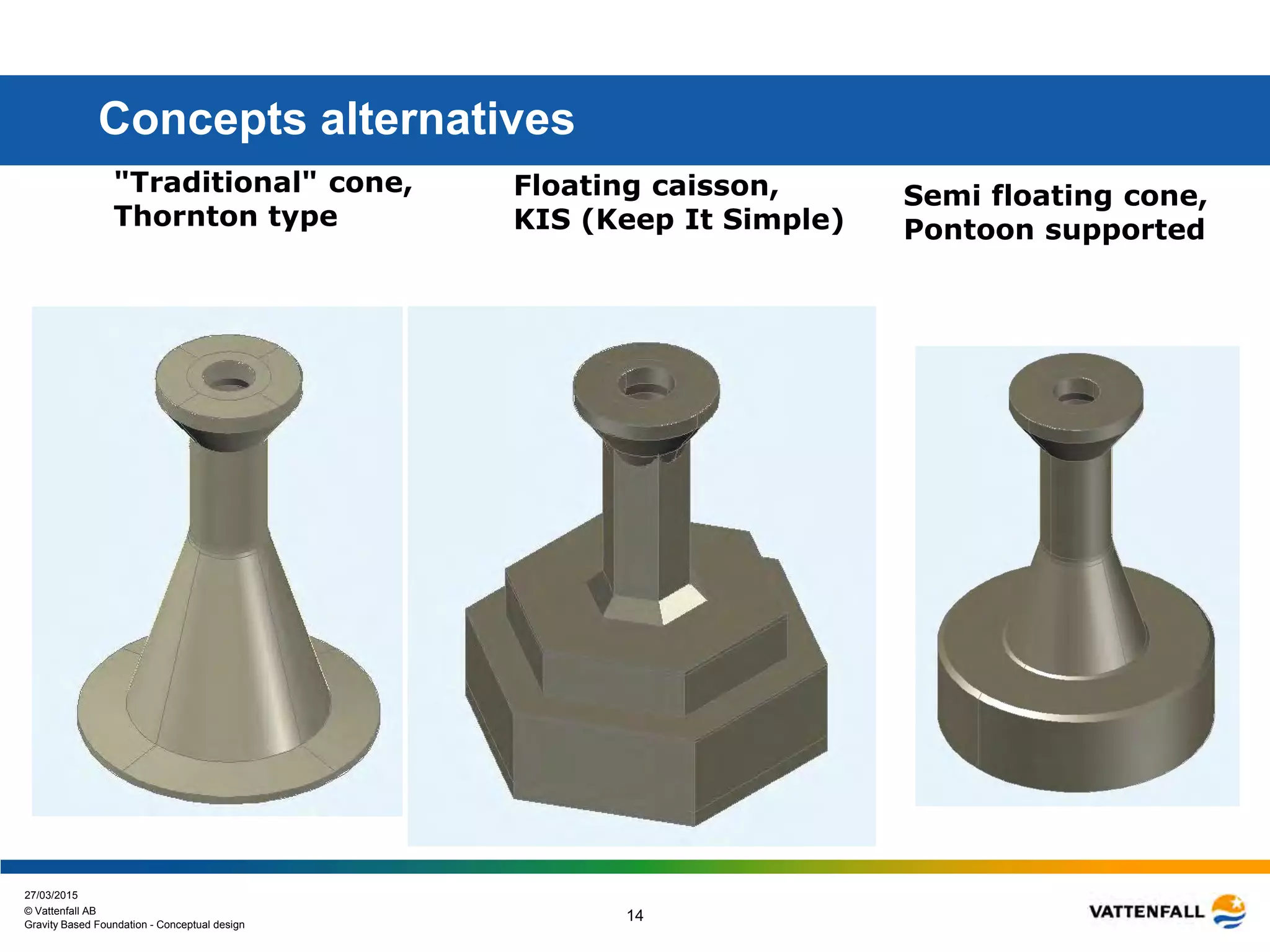

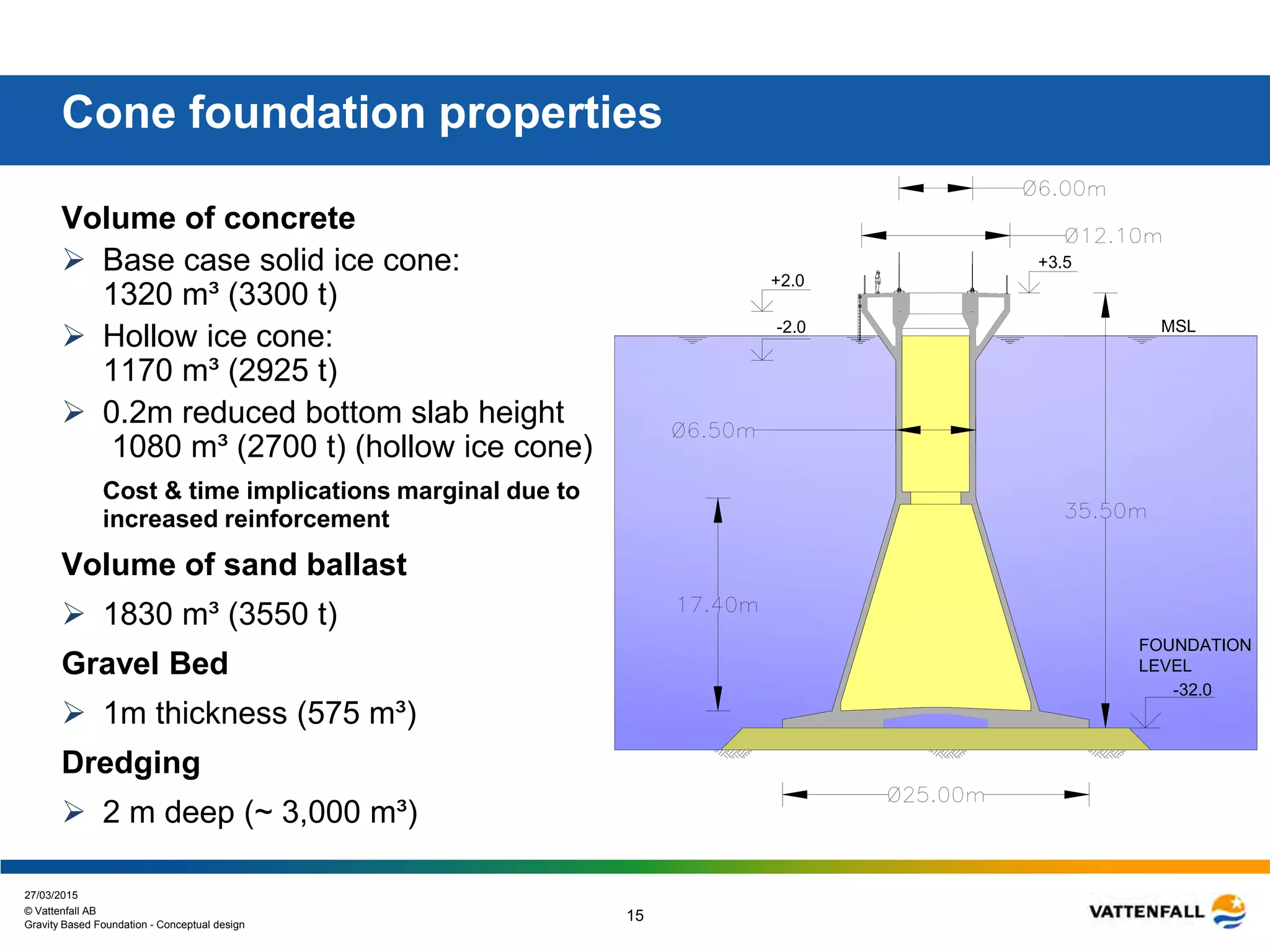

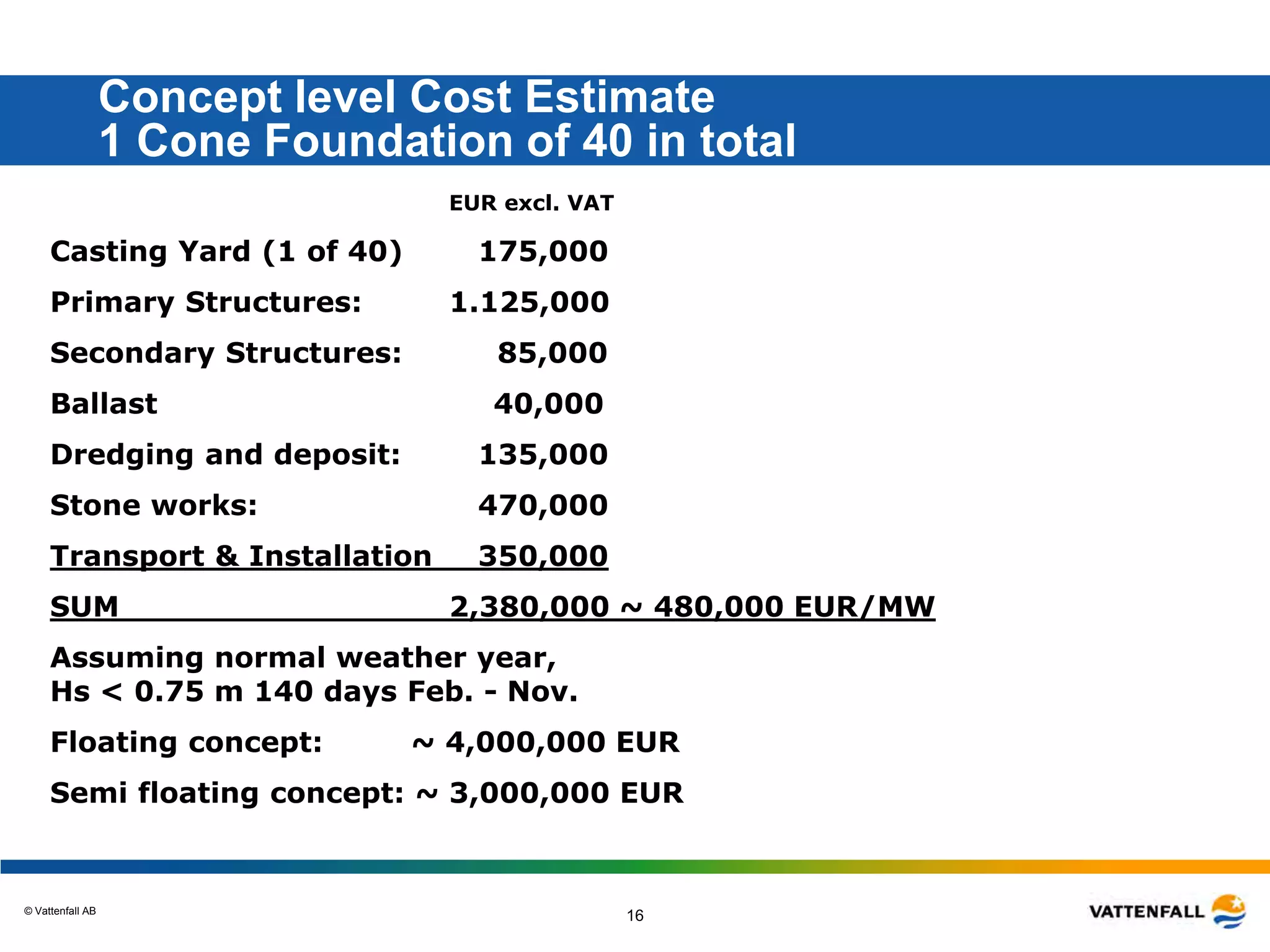

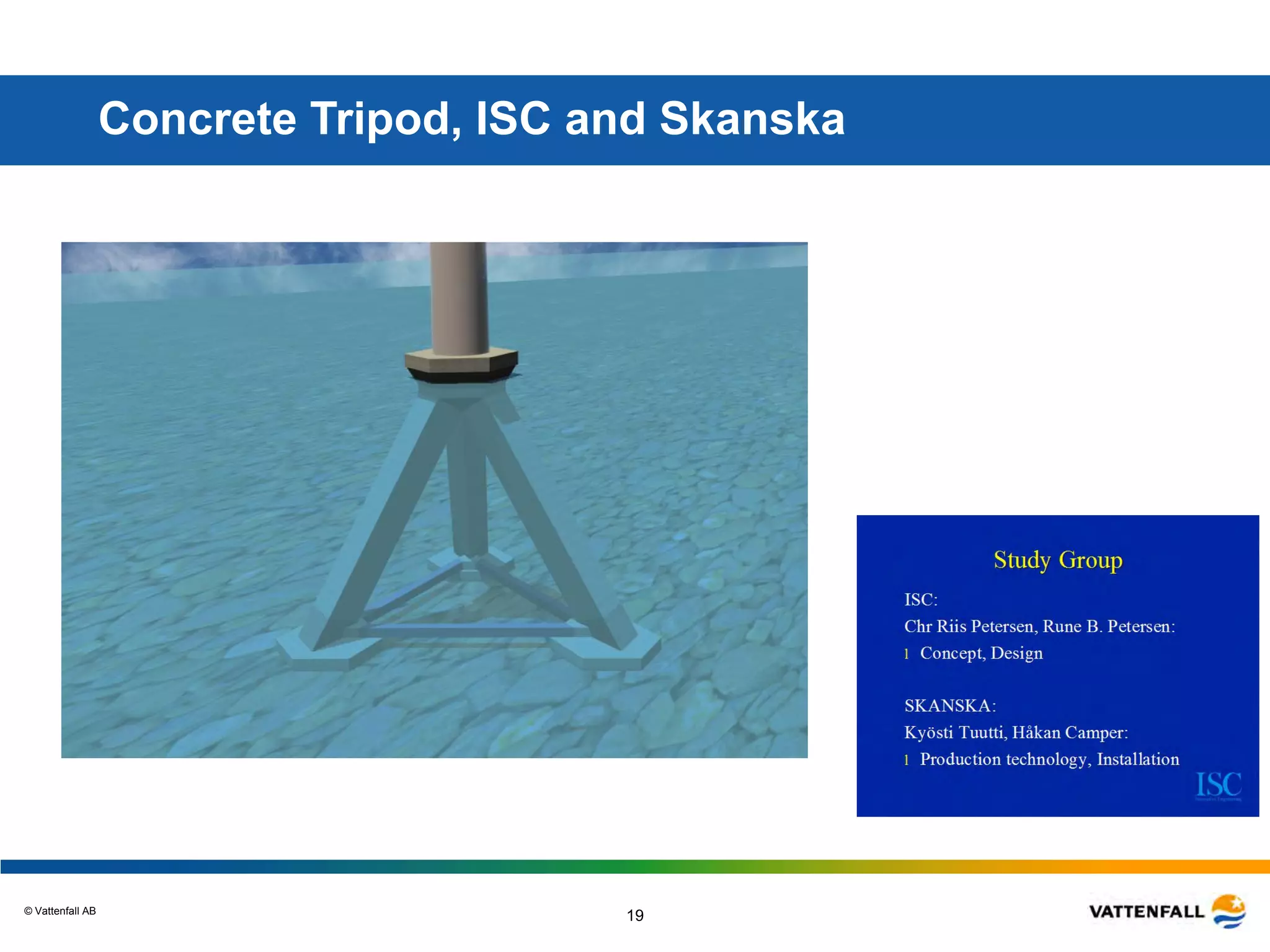

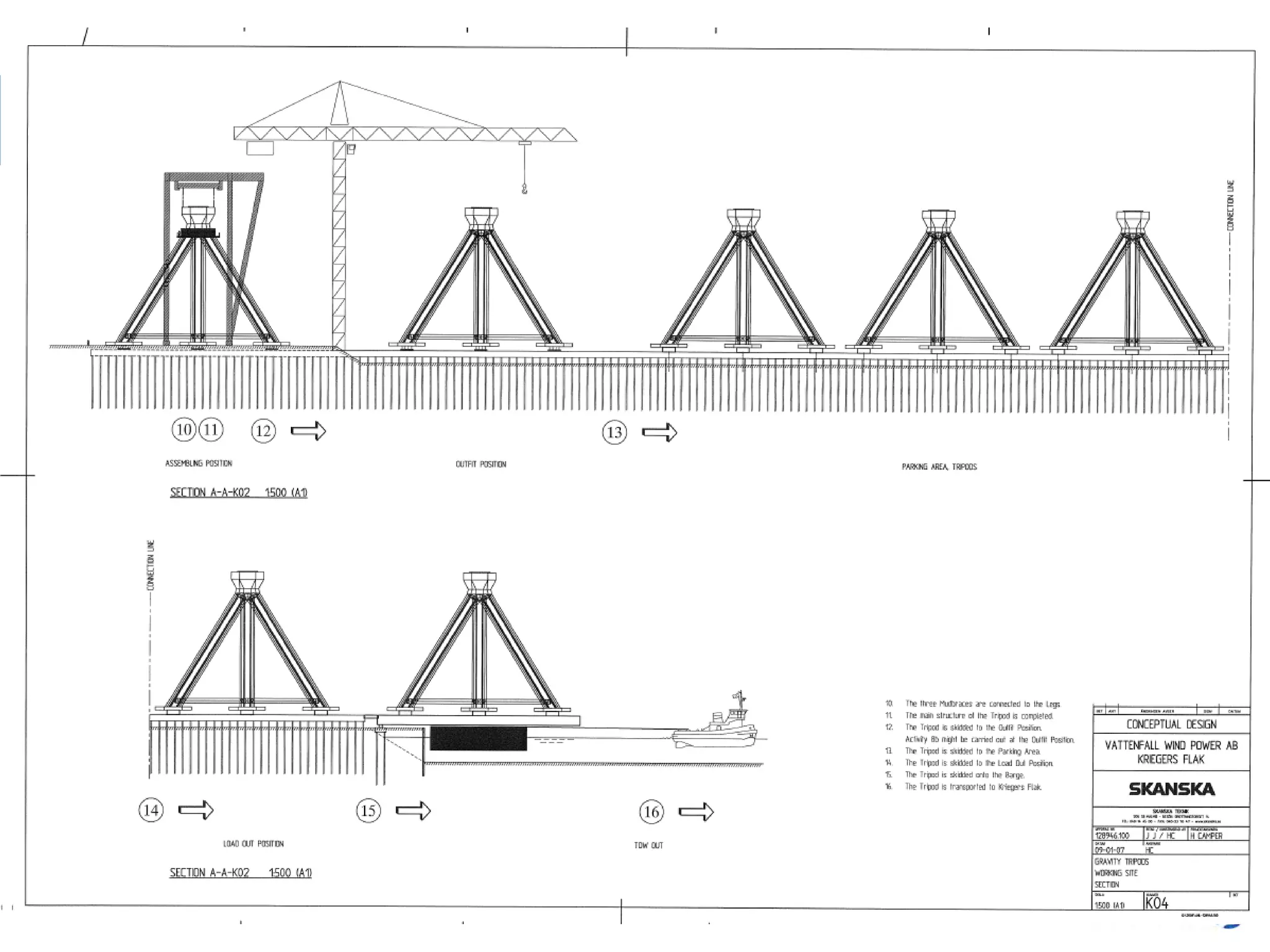

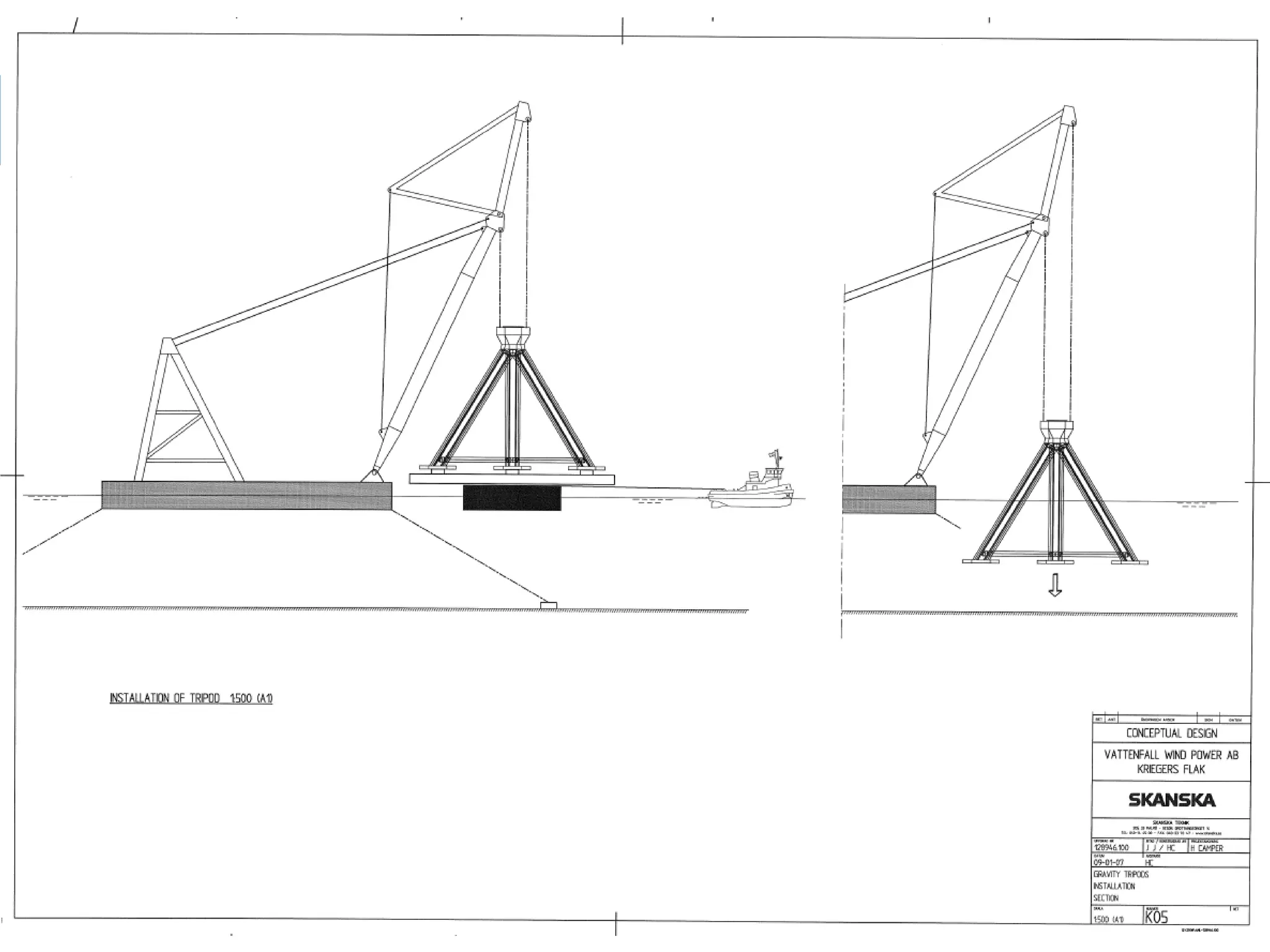

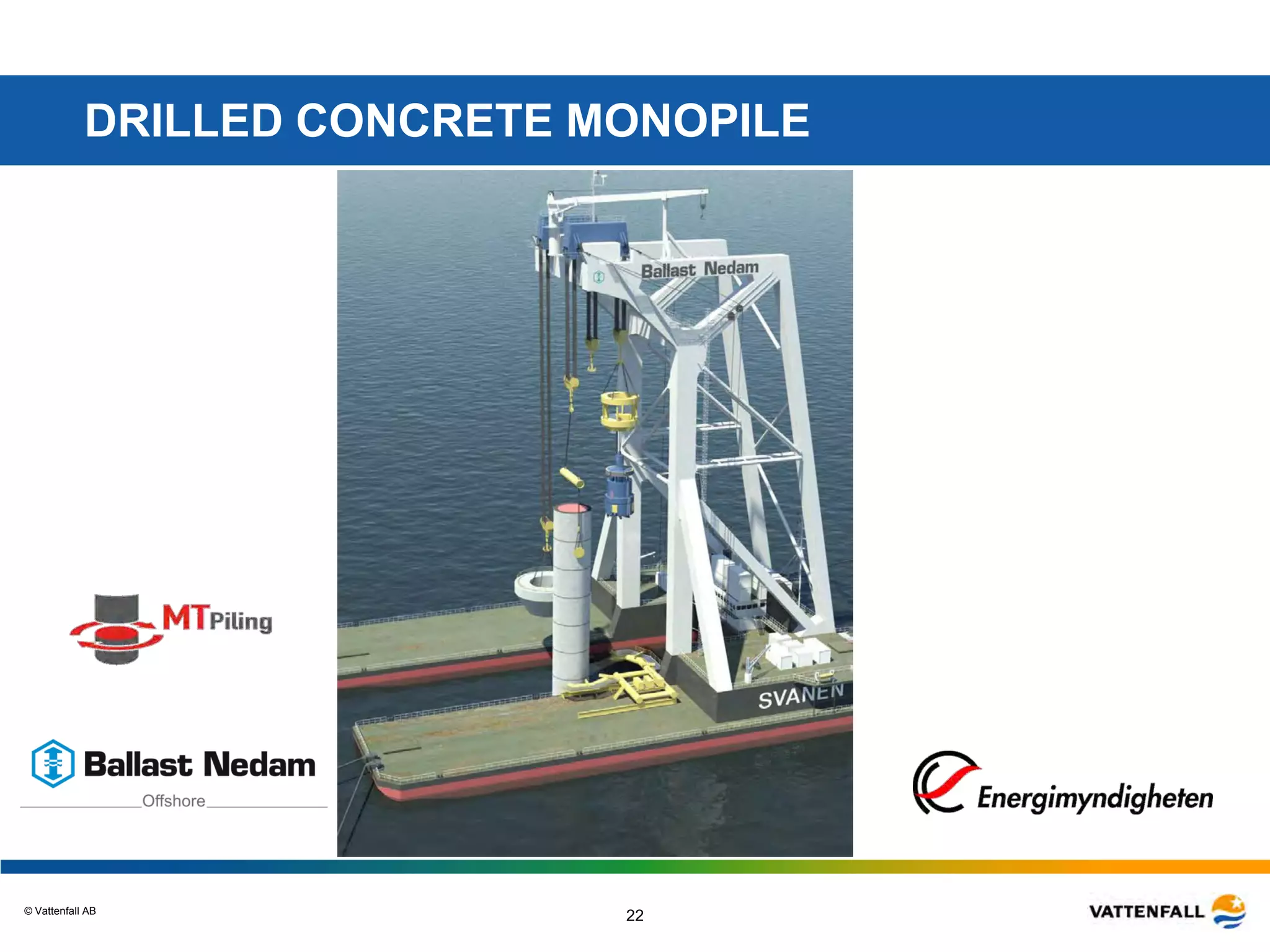

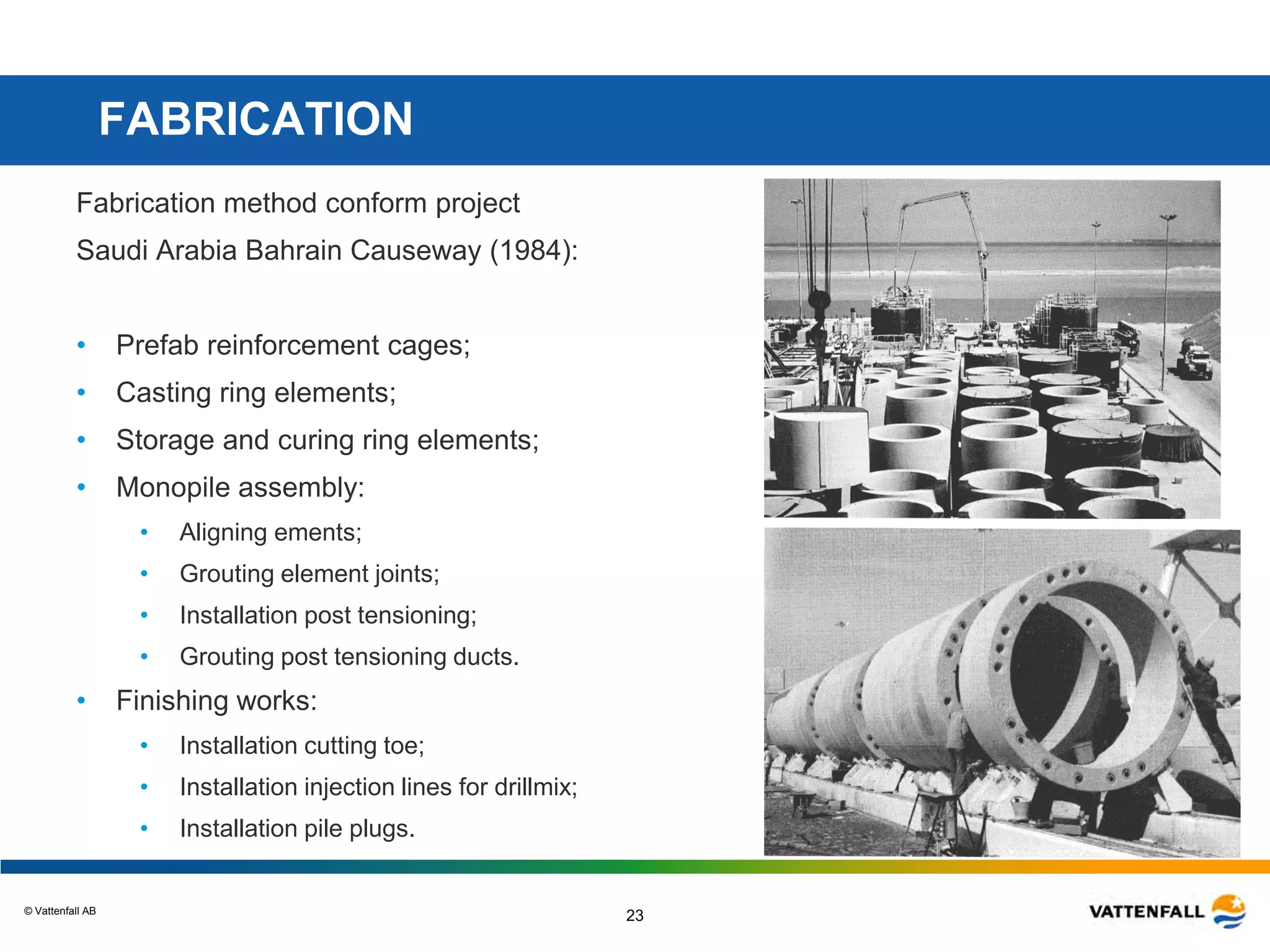

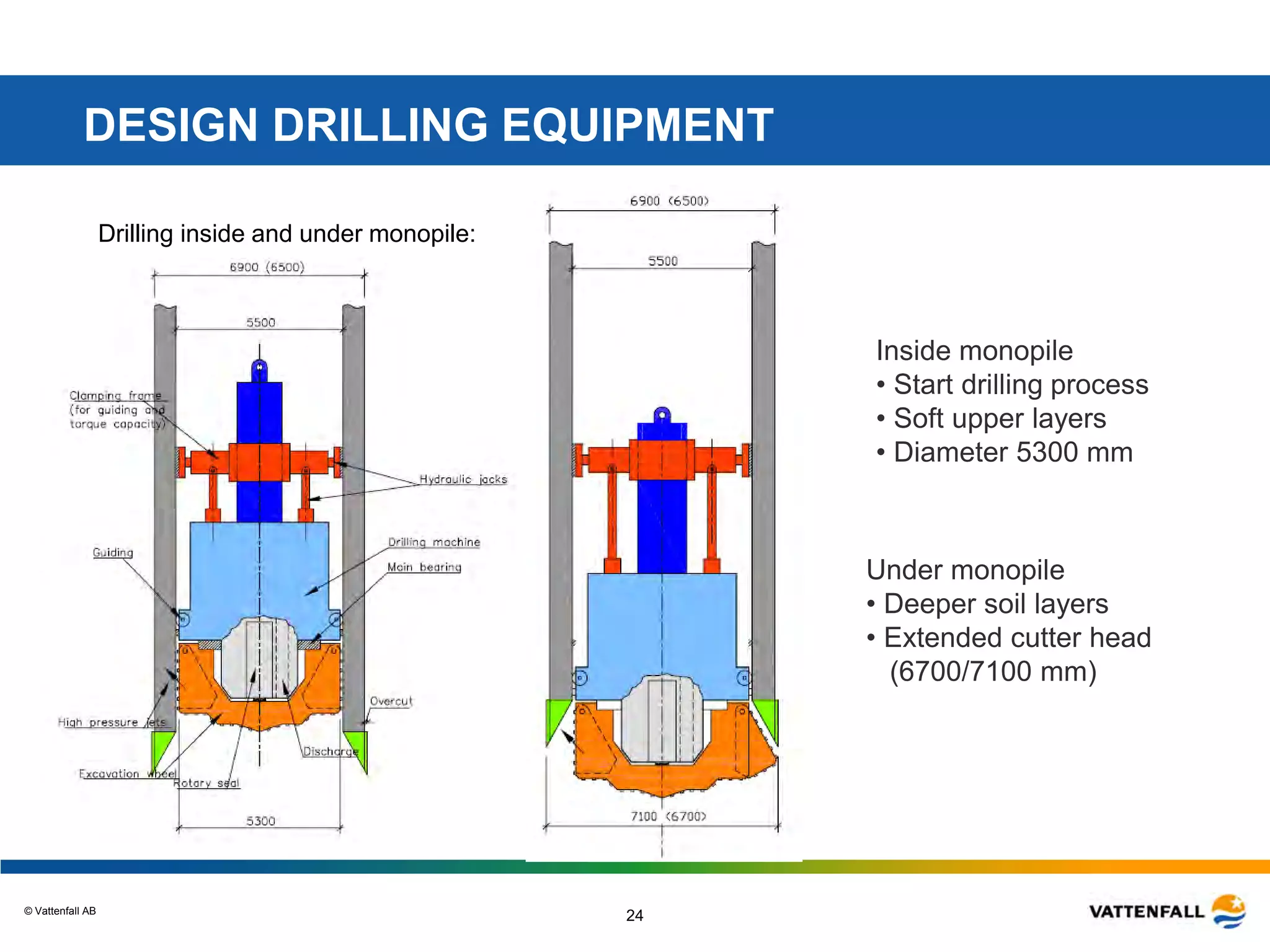

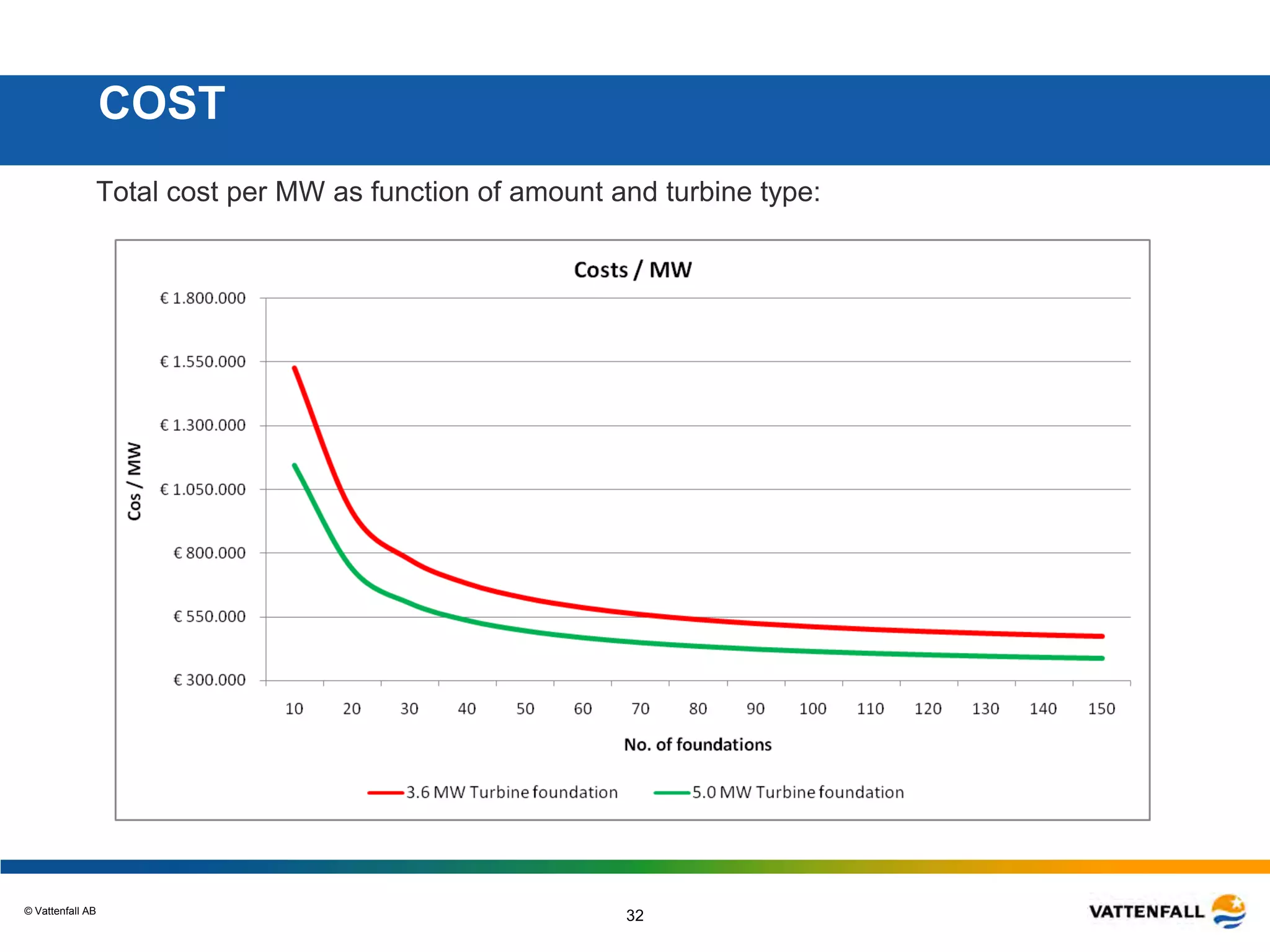

Vattenfall is a large European energy company with wind power activities in several countries. This document summarizes a conceptual design study for foundations for an offshore wind farm called Kriegers Flak in waters 15-45 meters deep. Five foundation concepts were developed - monopile, jacket, concrete tripod, gravity base cone foundation, and drilled concrete monopile. The study aimed to reduce costs and risks for the project planned to begin construction in 2013 through preliminary engineering of foundation options and establishing early contact with contractors.