This document is a curriculum vitae for Grant Hampson that provides personal and educational details. It includes:

- Personal details such as name, date of birth, contact information, and languages spoken.

- Secondary education details from 1998-2002 at Maritzburg College, including subjects and marks achieved.

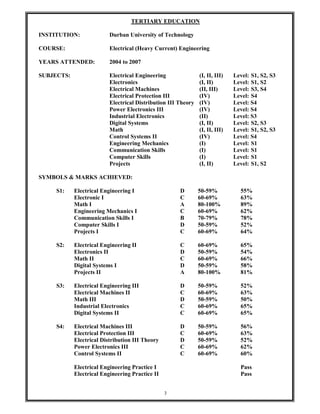

- Tertiary education details from 2004-2007 at Durban University of Technology studying Electrical Engineering, including subjects and marks.

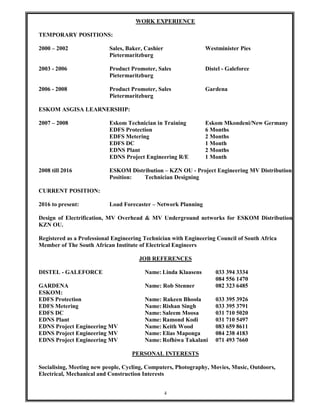

- Work experience starting in 2000 in various temporary positions, then from 2007-2016 with Eskom in different departments including protection, metering, direct current, plant, and project engineering. Current position since 2016 is as a load forecaster.