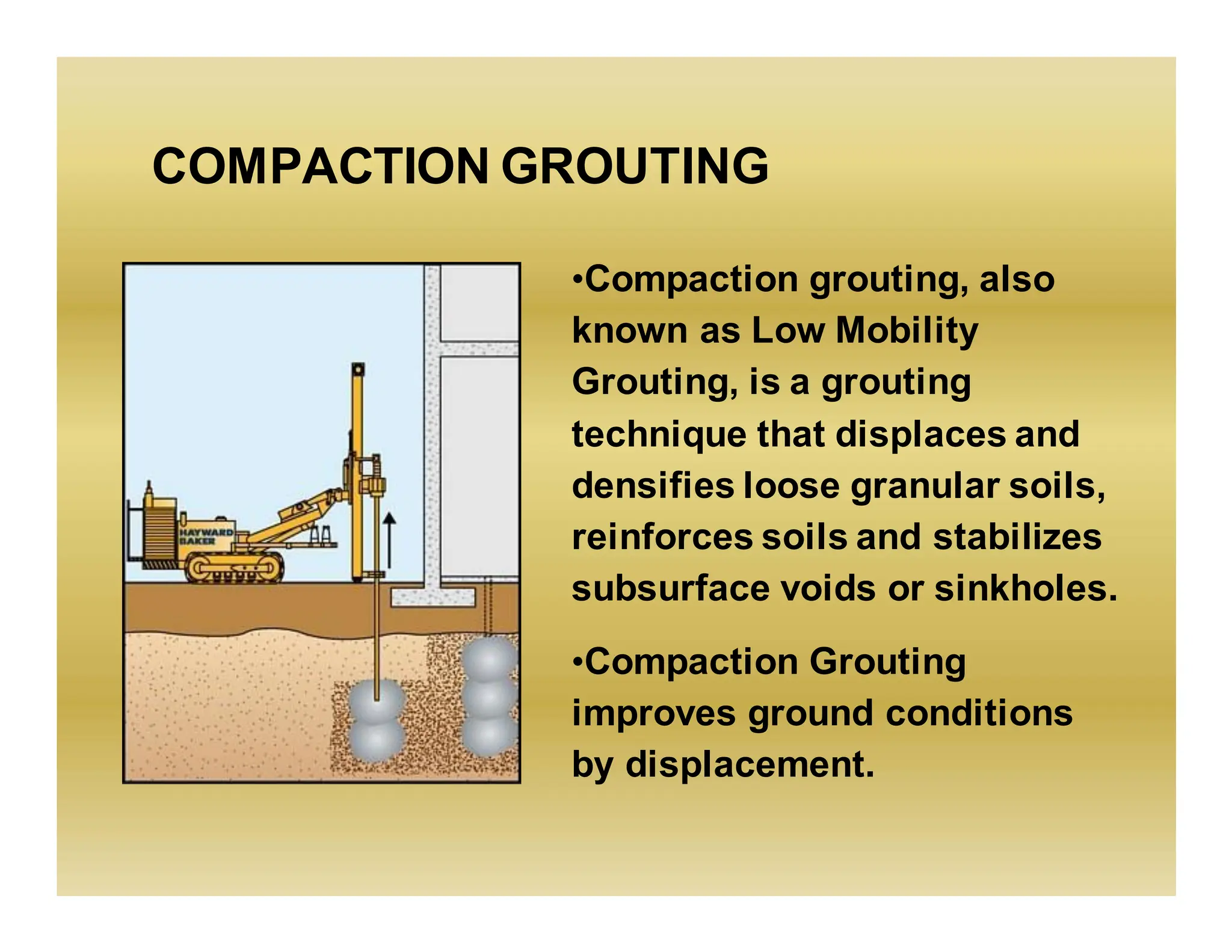

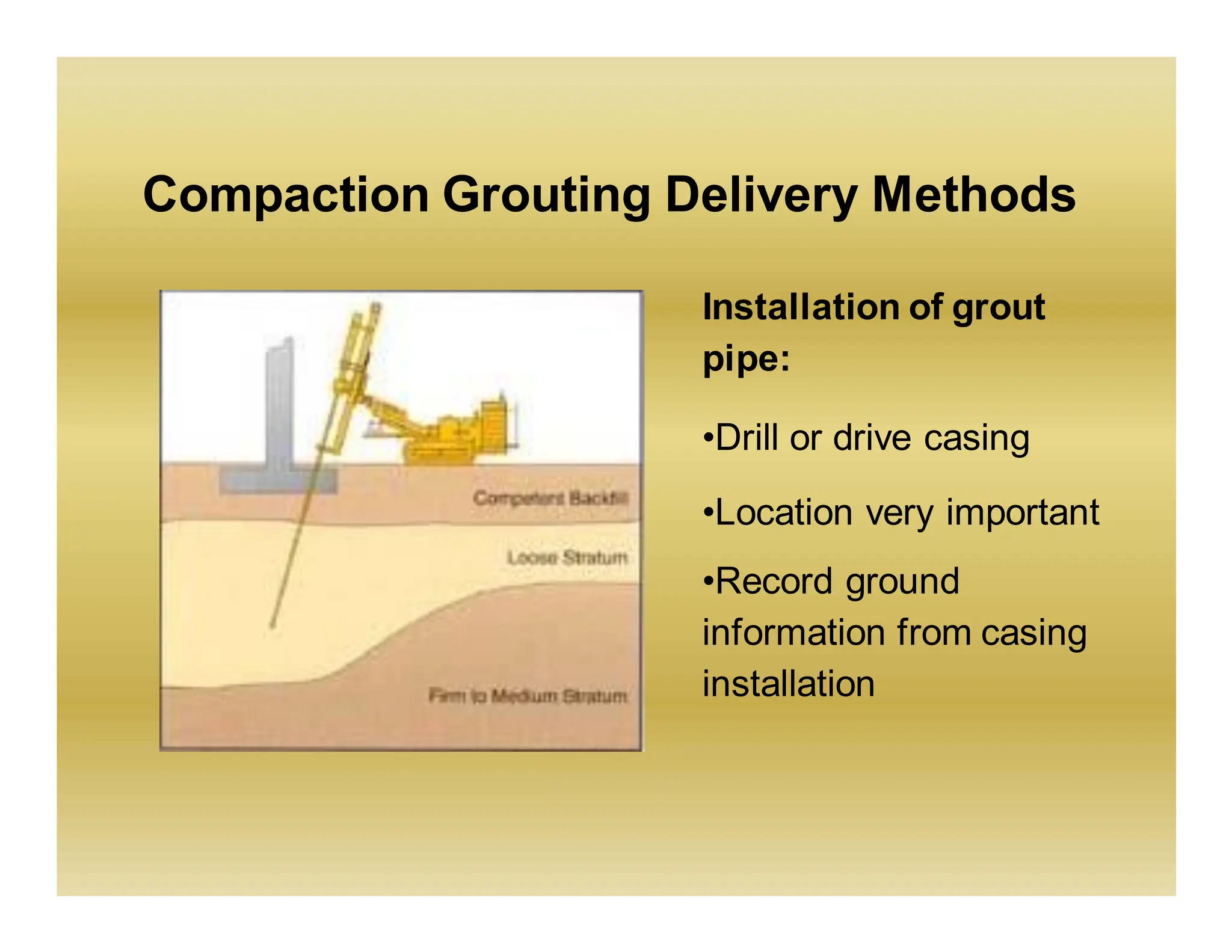

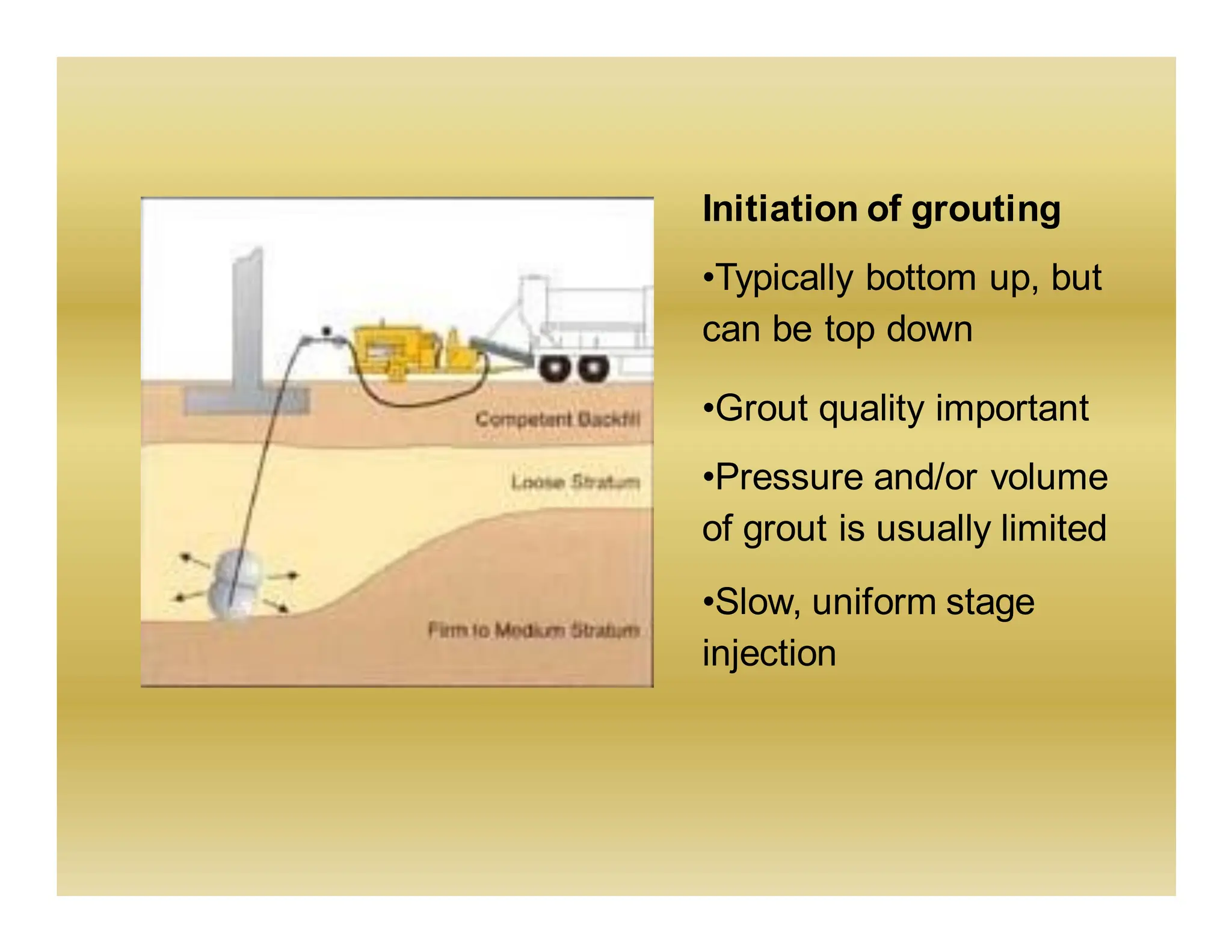

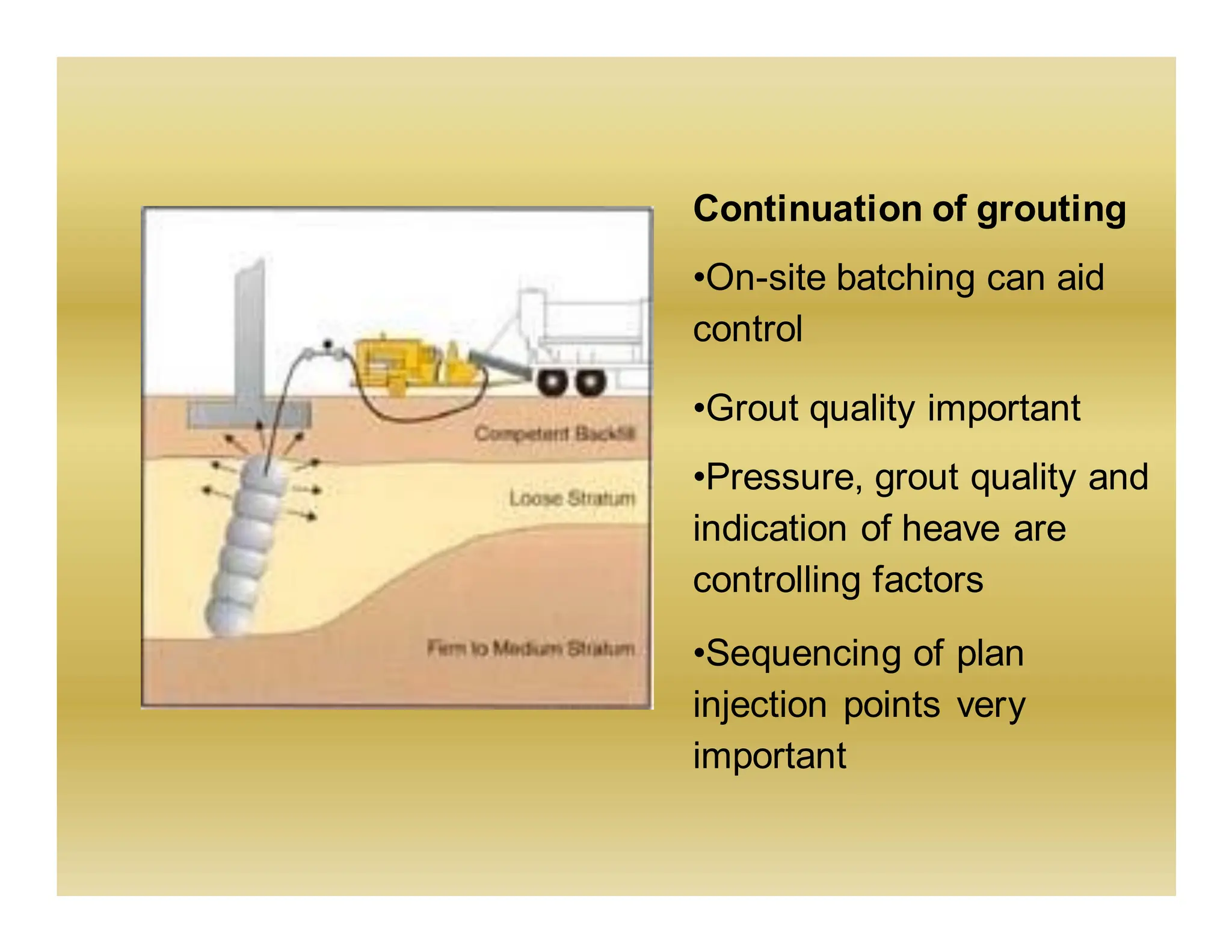

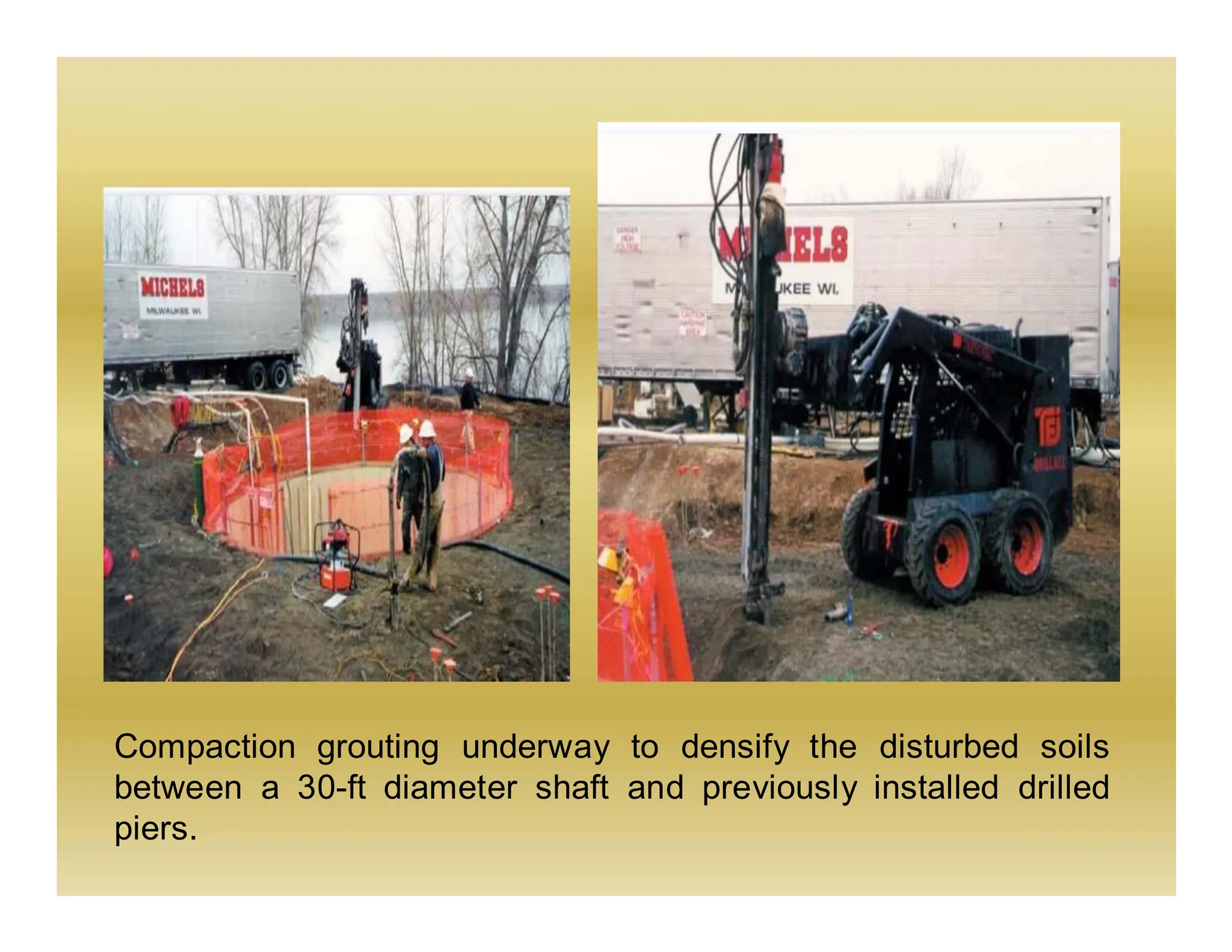

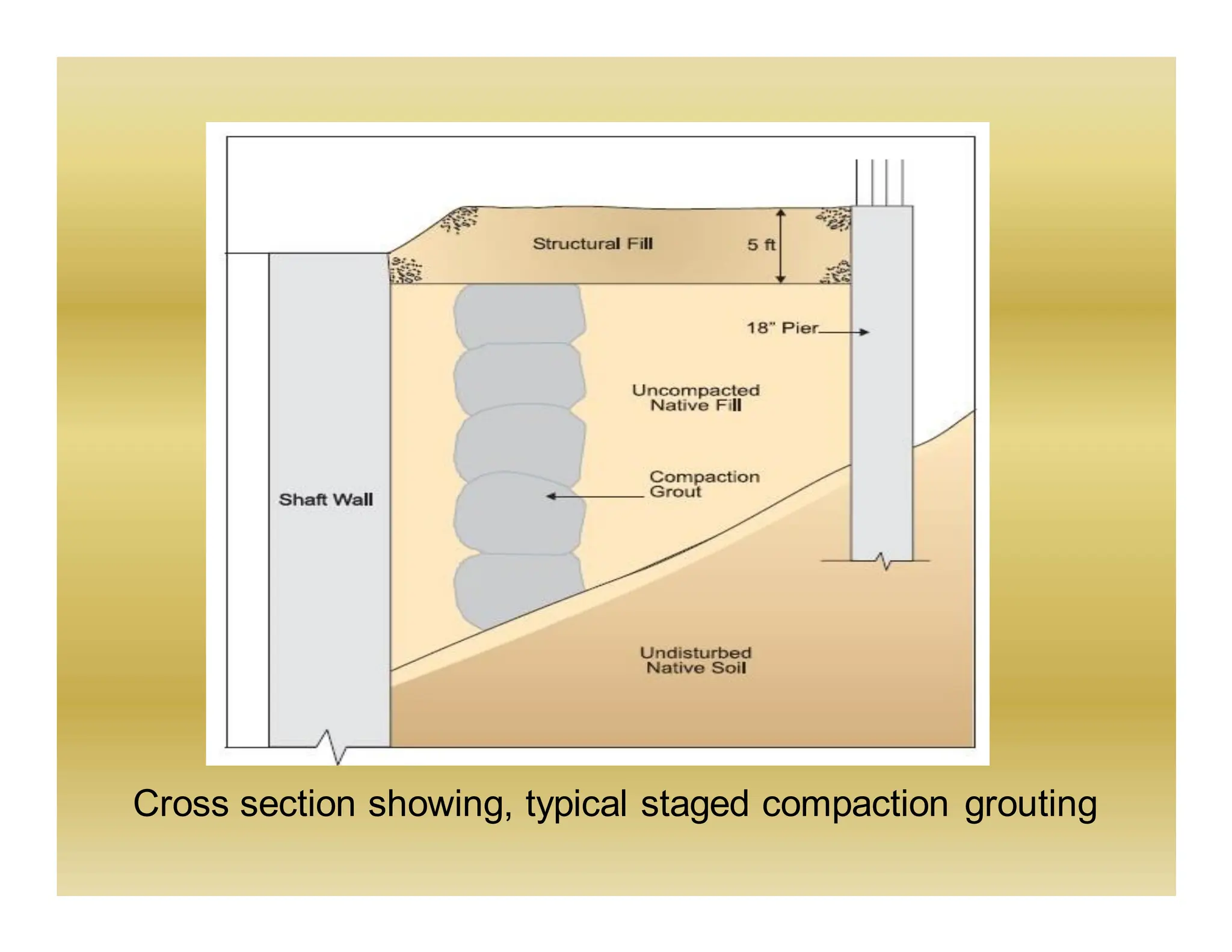

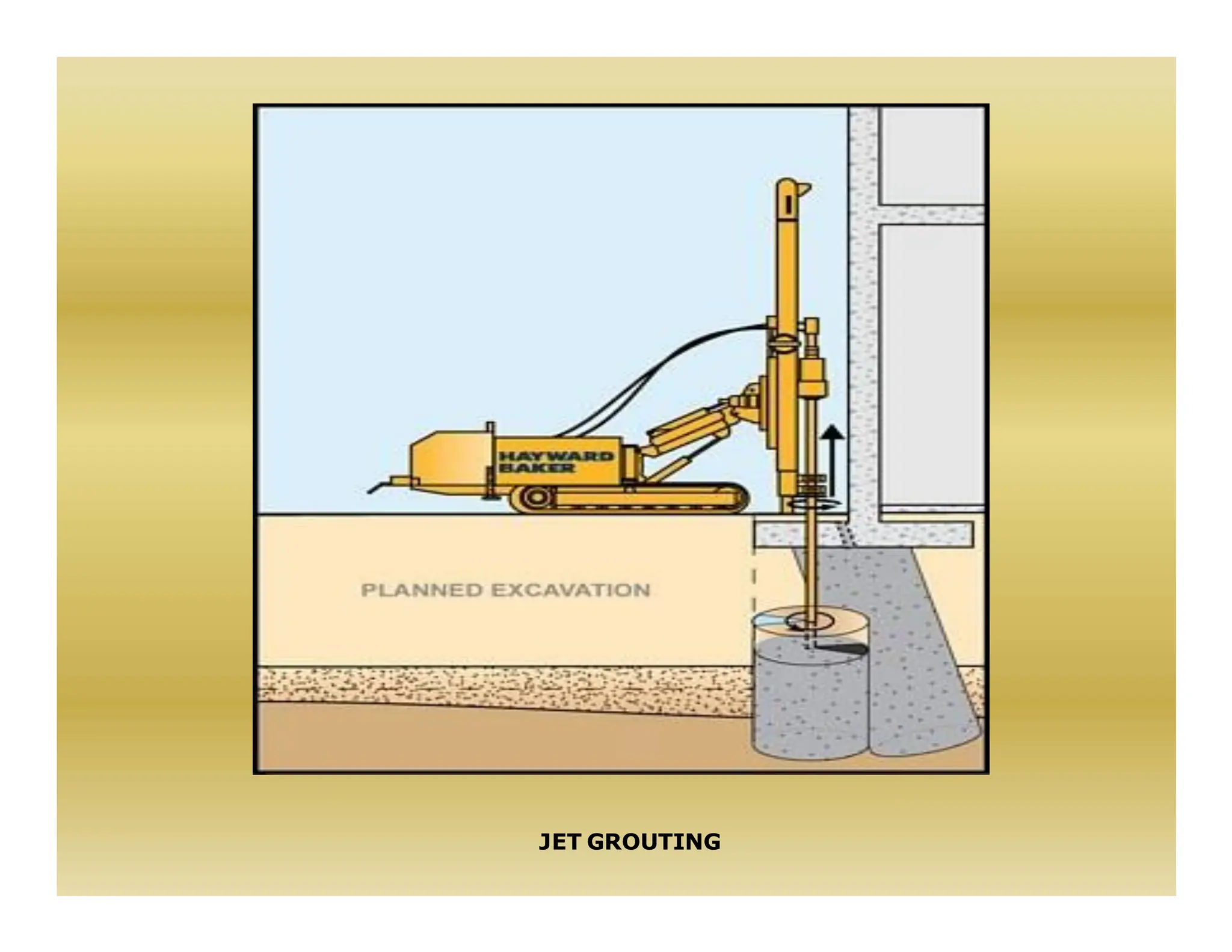

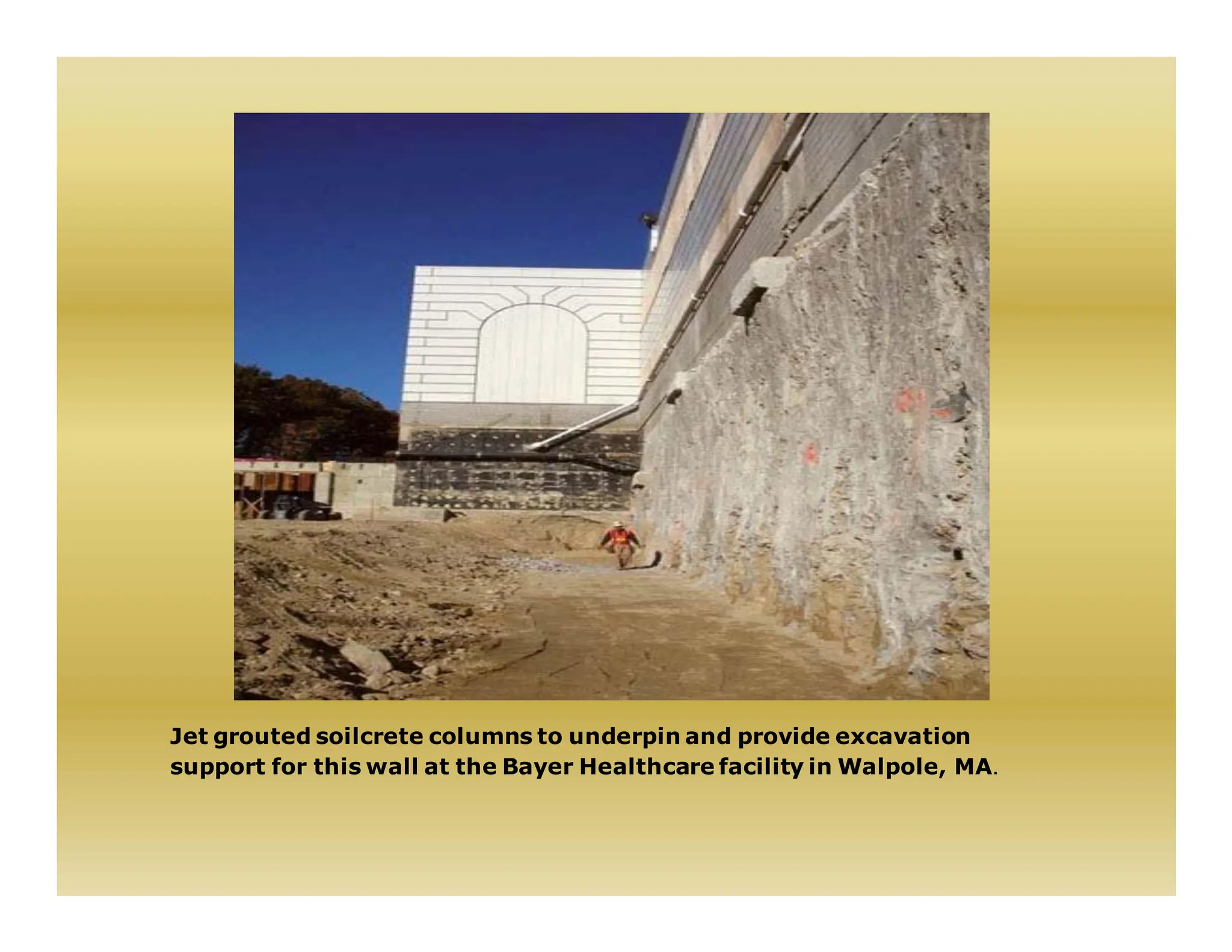

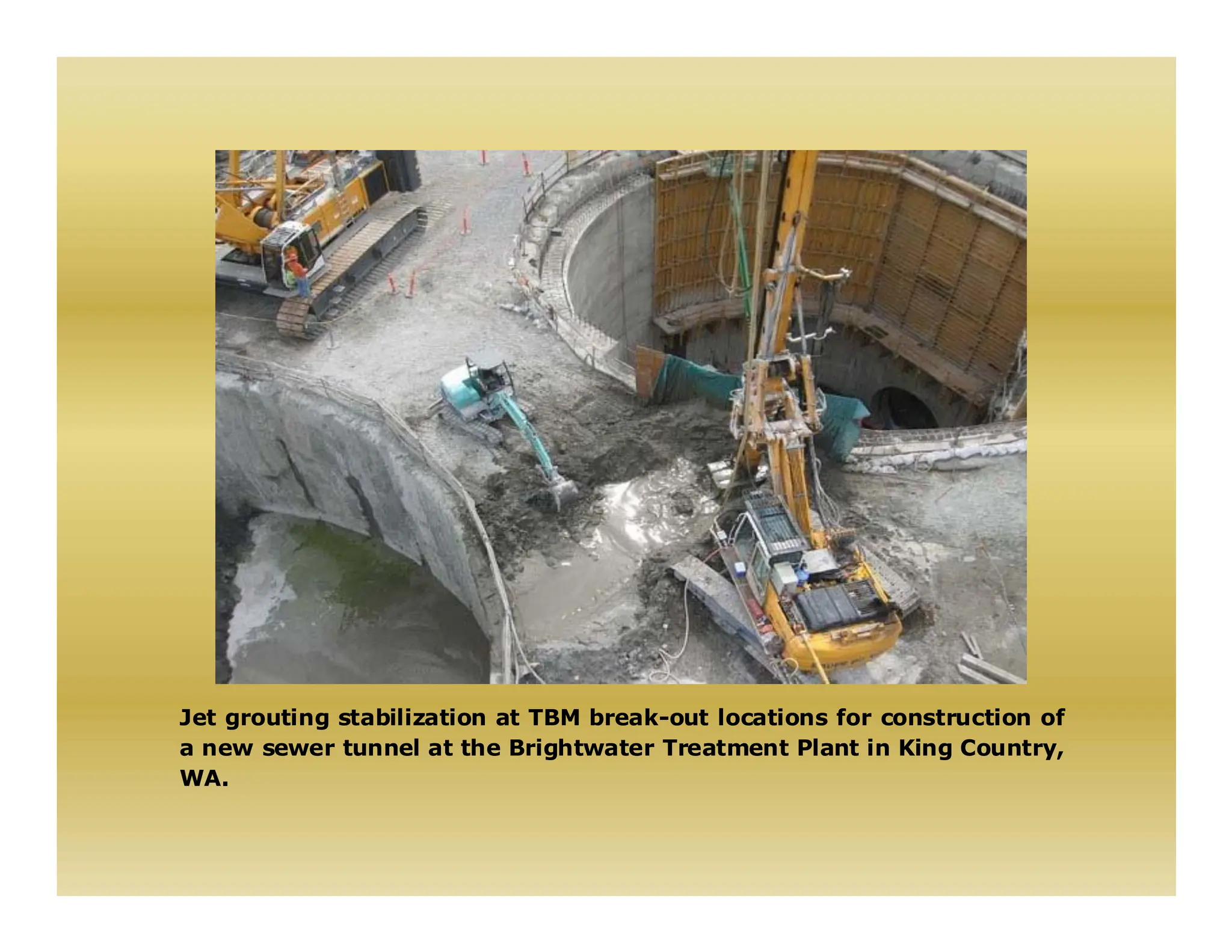

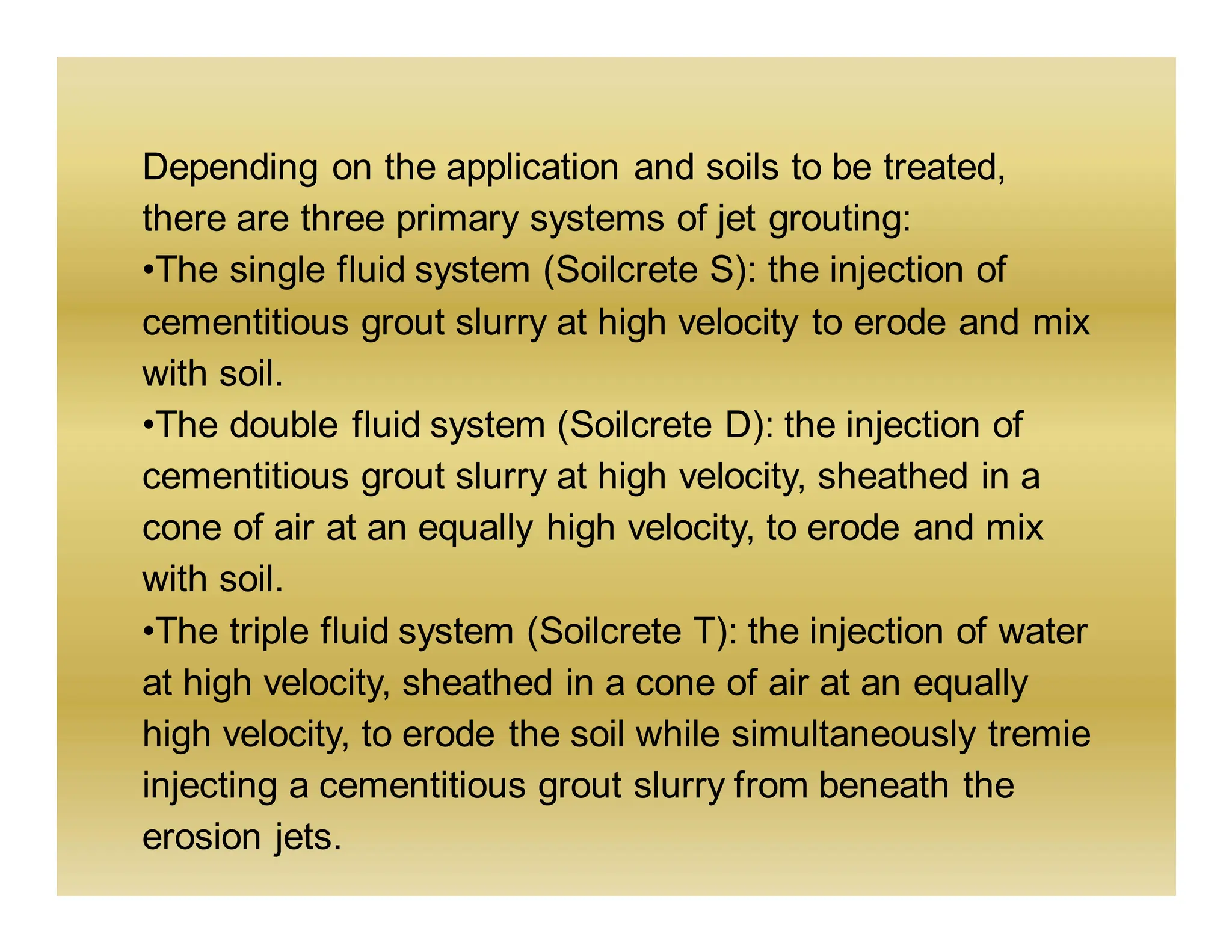

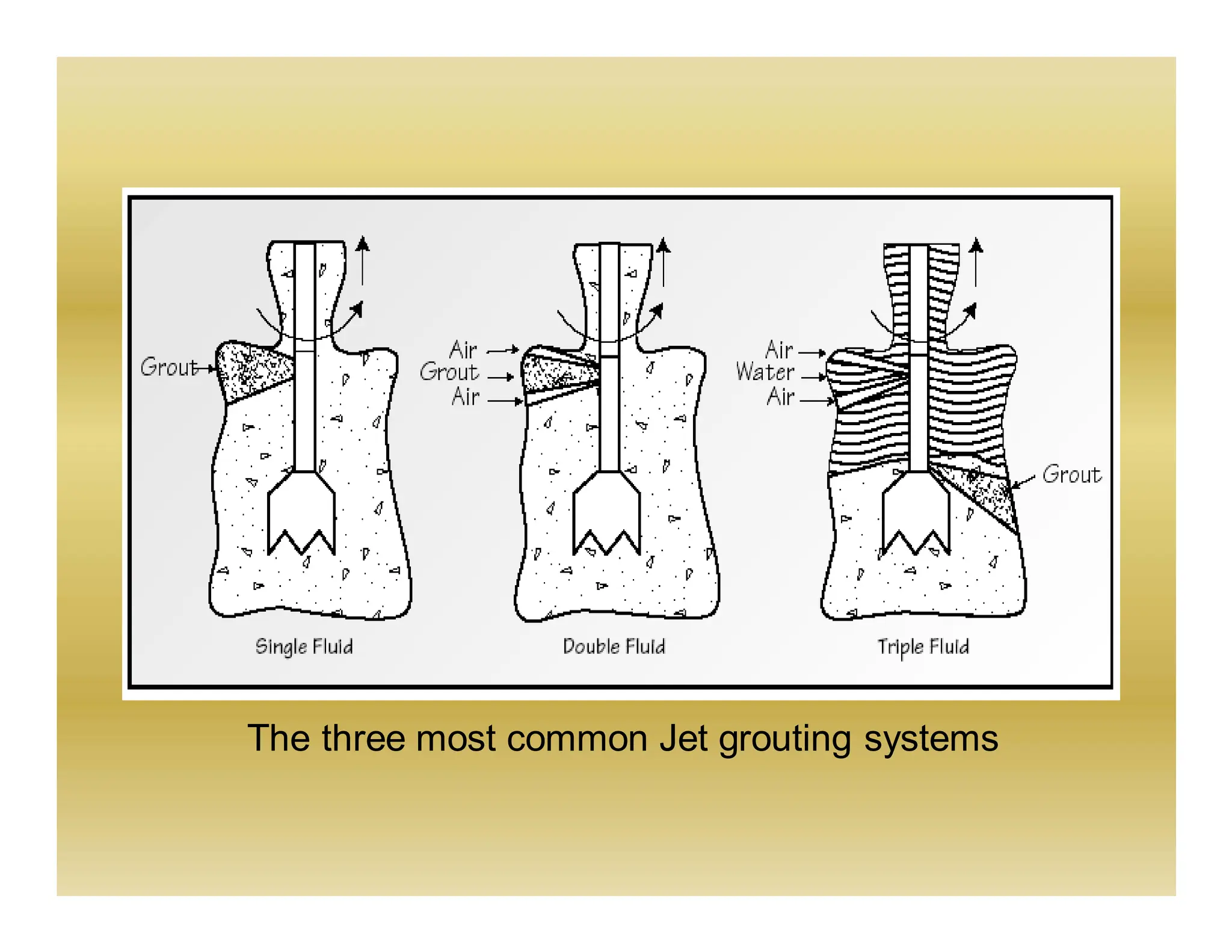

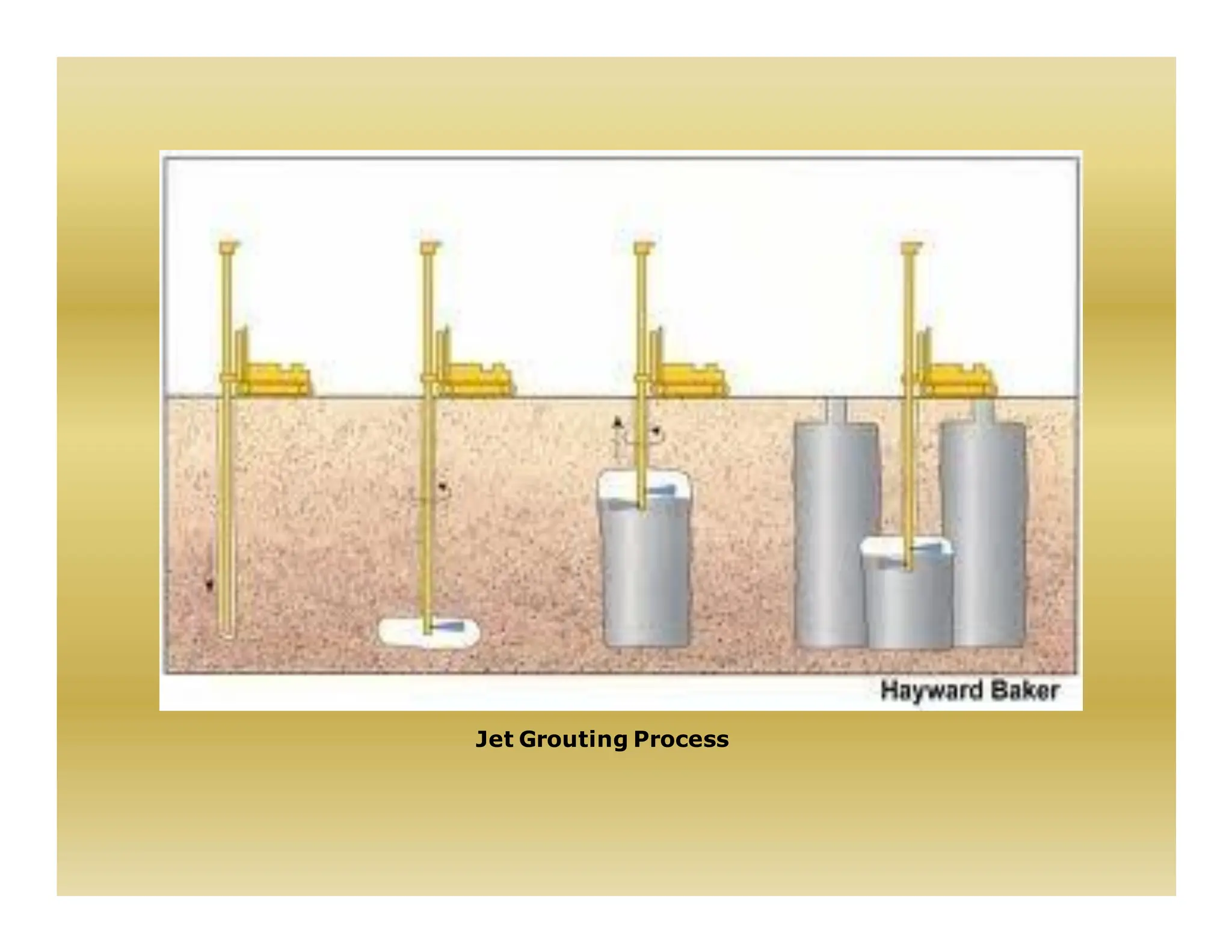

Compaction grouting is a technique used to densify loose granular soils and stabilize subsurface voids, requiring careful site investigation and consideration of soil conditions for effective application. It is particularly useful in various construction scenarios, including treatment of collapsible soils and poorly placed fill, and offers advantages such as pinpoint treatment and applicability in tight spaces. Jet grouting is another technique mentioned that involves creating soilcrete to reinforce areas, utilizing high-velocity fluid jets for mixing and treating soil.