Embed presentation

Download as PDF, PPTX

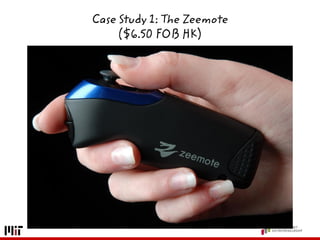

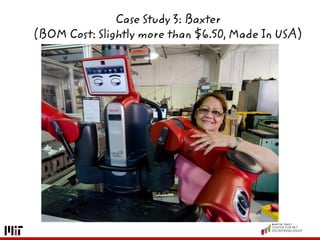

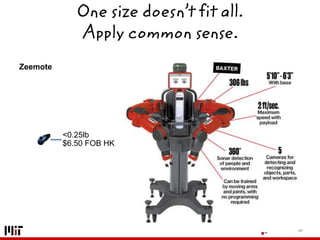

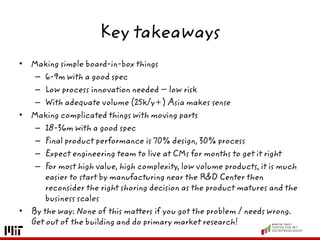

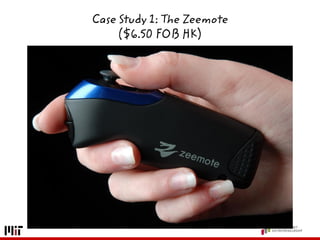

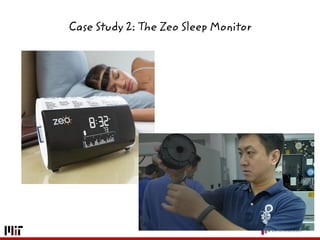

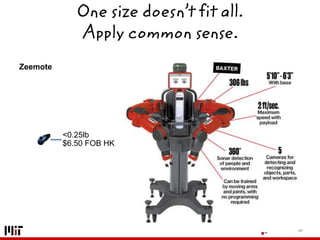

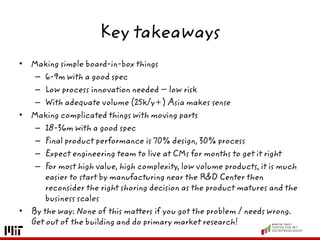

The document discusses the Martin Trust Center for MIT Entrepreneurship, highlighting its role in fostering innovation and entrepreneurship at MIT. It presents two case studies: the Zeemote and the Zeo sleep monitor, detailing key learnings about manufacturing processes for different product complexities. The importance of thorough market research before product development is emphasized to ensure the right problem is being solved.