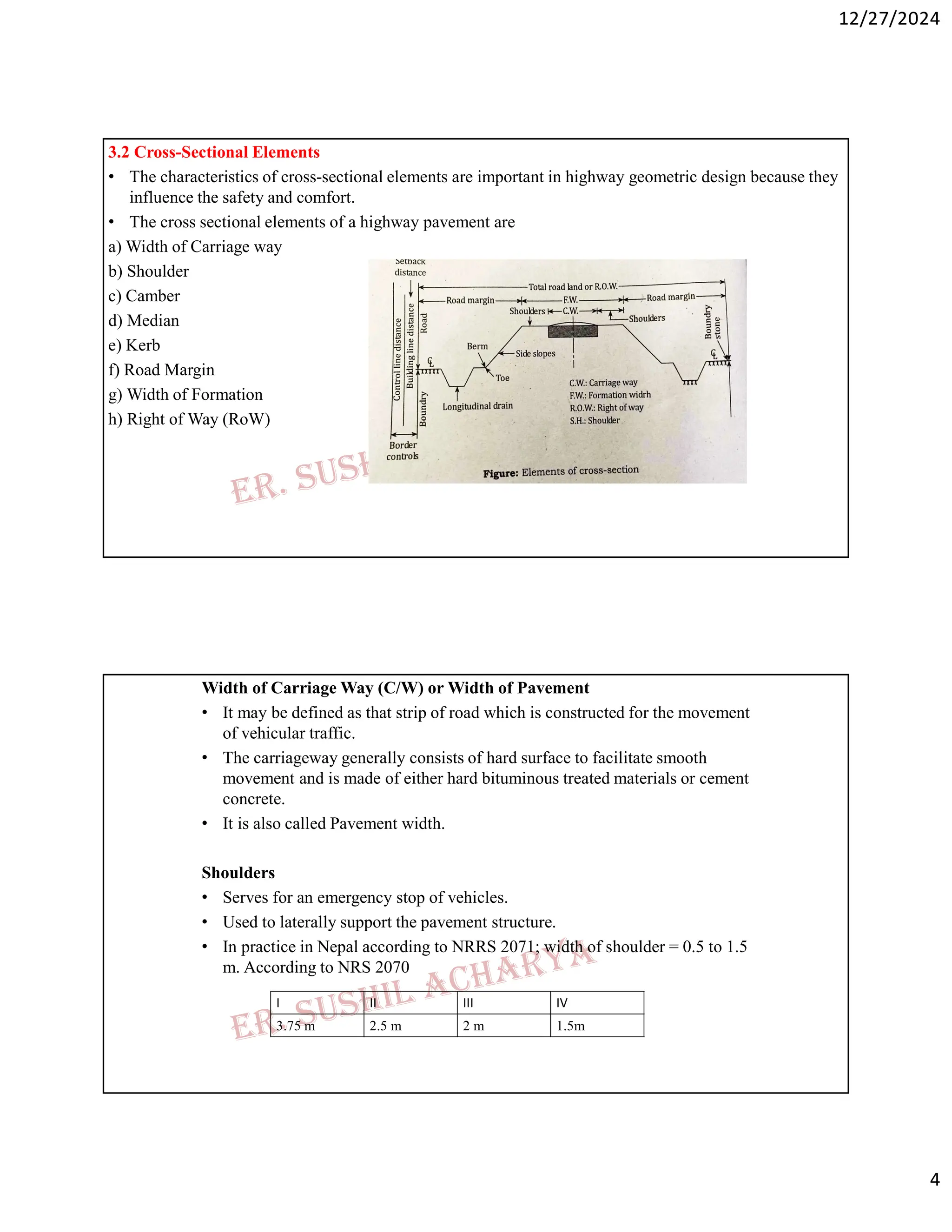

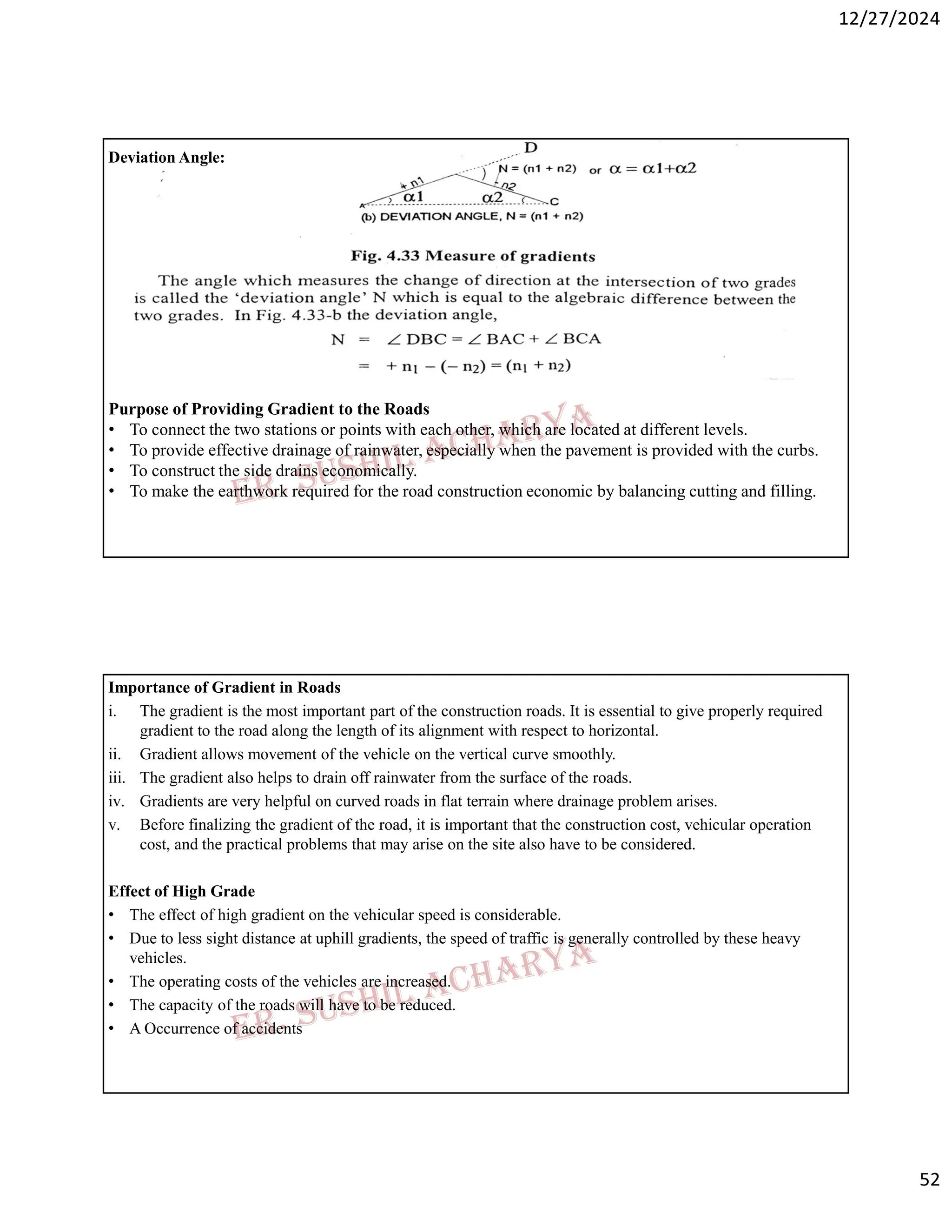

The document outlines the geometric design of highways, focusing on dimensions, alignments, sight distances, and safety standards required for efficient traffic operation. Key factors influencing the design include design speed, terrain, traffic characteristics, and environmental considerations, with detailed elements such as cross sections, camber, and superelevation discussed. Various road features such as carriageways, shoulders, sidewalks, and medians are described along with their functions in enhancing road safety and traffic management.

![12/27/2024

9

Functions:

• To separate different lanes of road.

• To strengthen and protect pavement edge. To facilitate and control drainage

• To provide good aesthetic appearance.

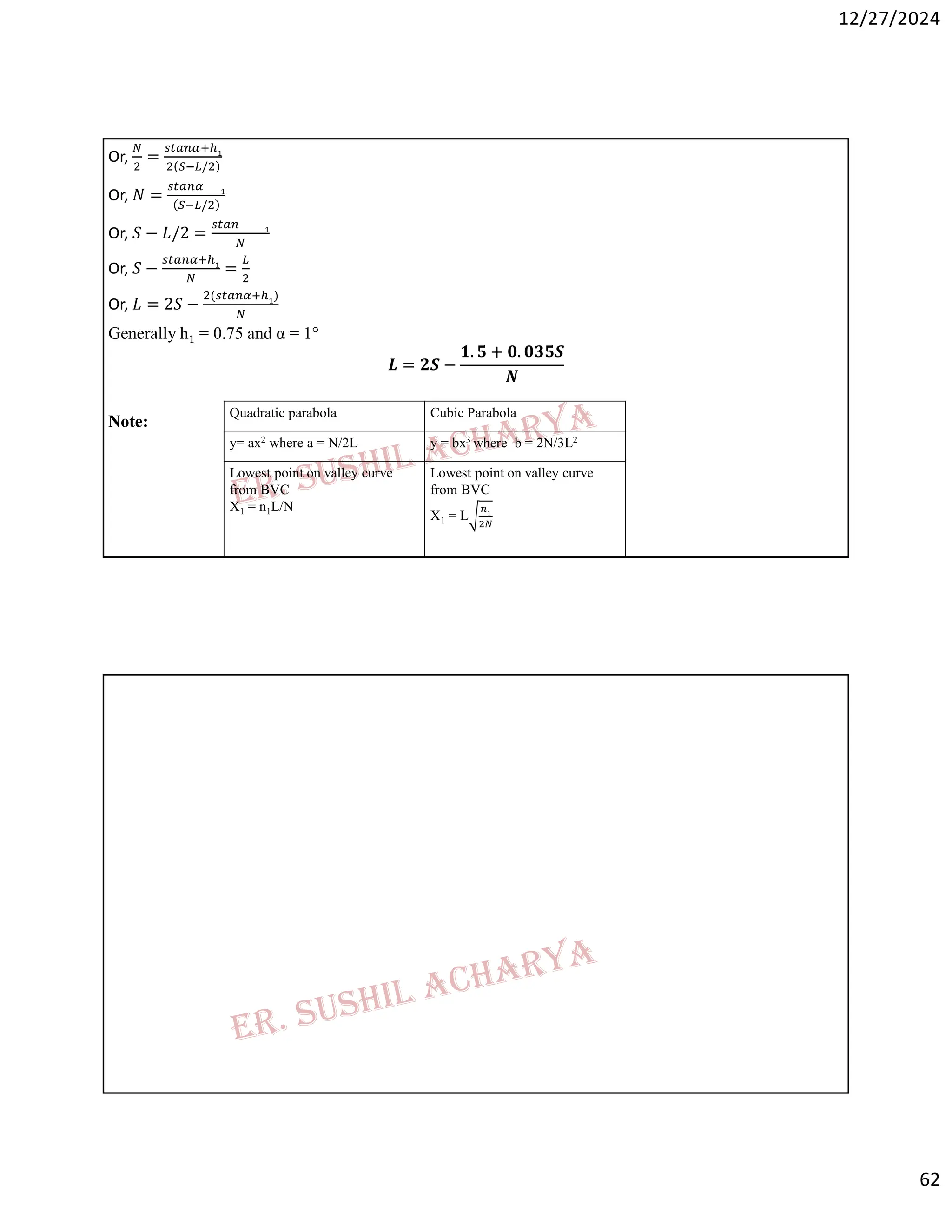

3.2.1 Rural Roads

District road/ core network(in hill)

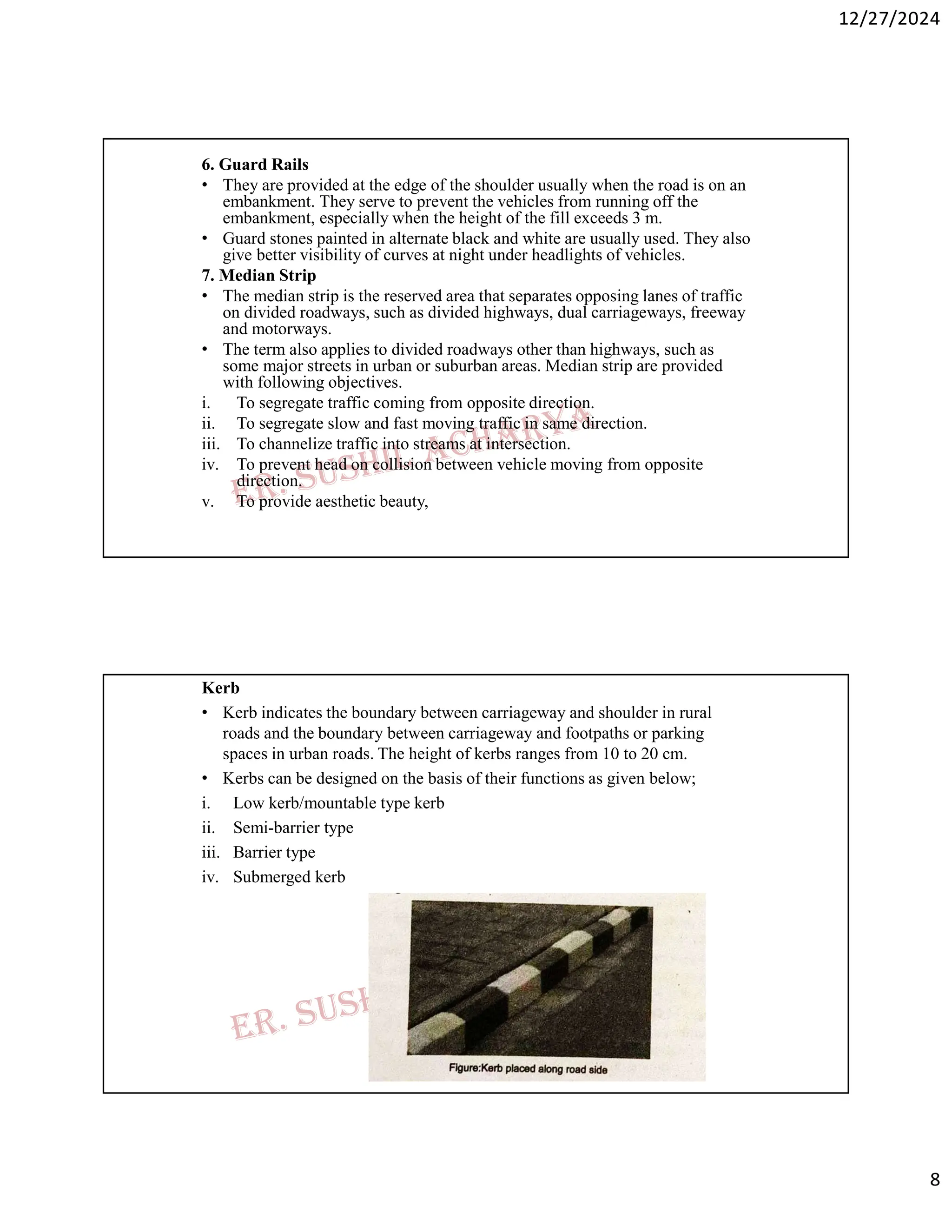

3.2.2Camber or Cross Slope or Cross Fall

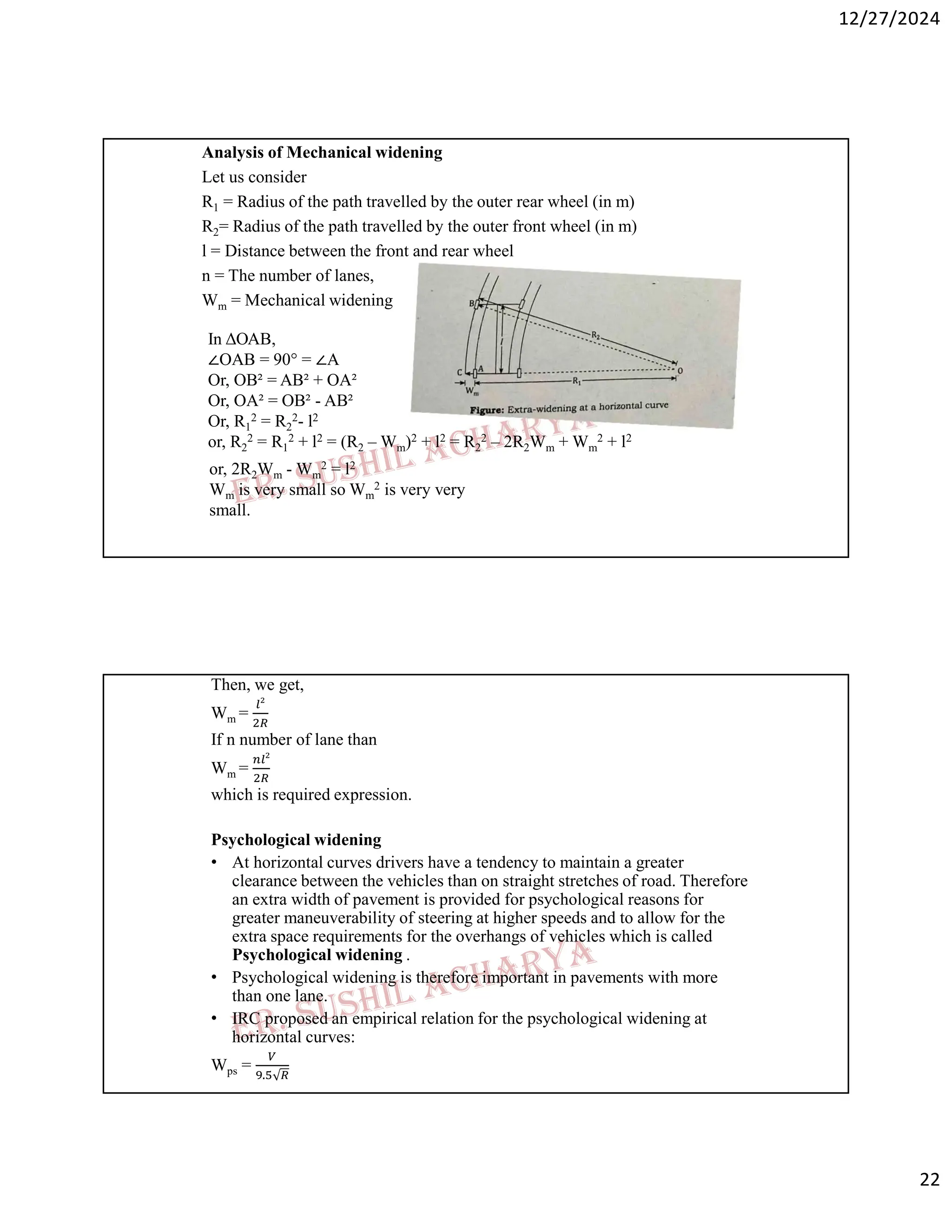

• A Camber is the cross slope provided to raise middle of the road surface in

the transverse direction to drain off rain water from road surface. It is

expressed as % or 1 in N

Objectives of Camber

The main objectives of providing camber for road construction are:

• Surface protection[Mainly for the bituminous or gravel roads].

• Facilitate quick drying of the Pavement. This helps to increase the safety.

• Proper drainage which helps to protect the sub-grade.](https://image.slidesharecdn.com/geo-second-last-250121143039-84a0dceb/75/geo-second-last-pdf-bbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbb-bggggggggggggggggggggggggg-9-2048.jpg)

![12/27/2024

61

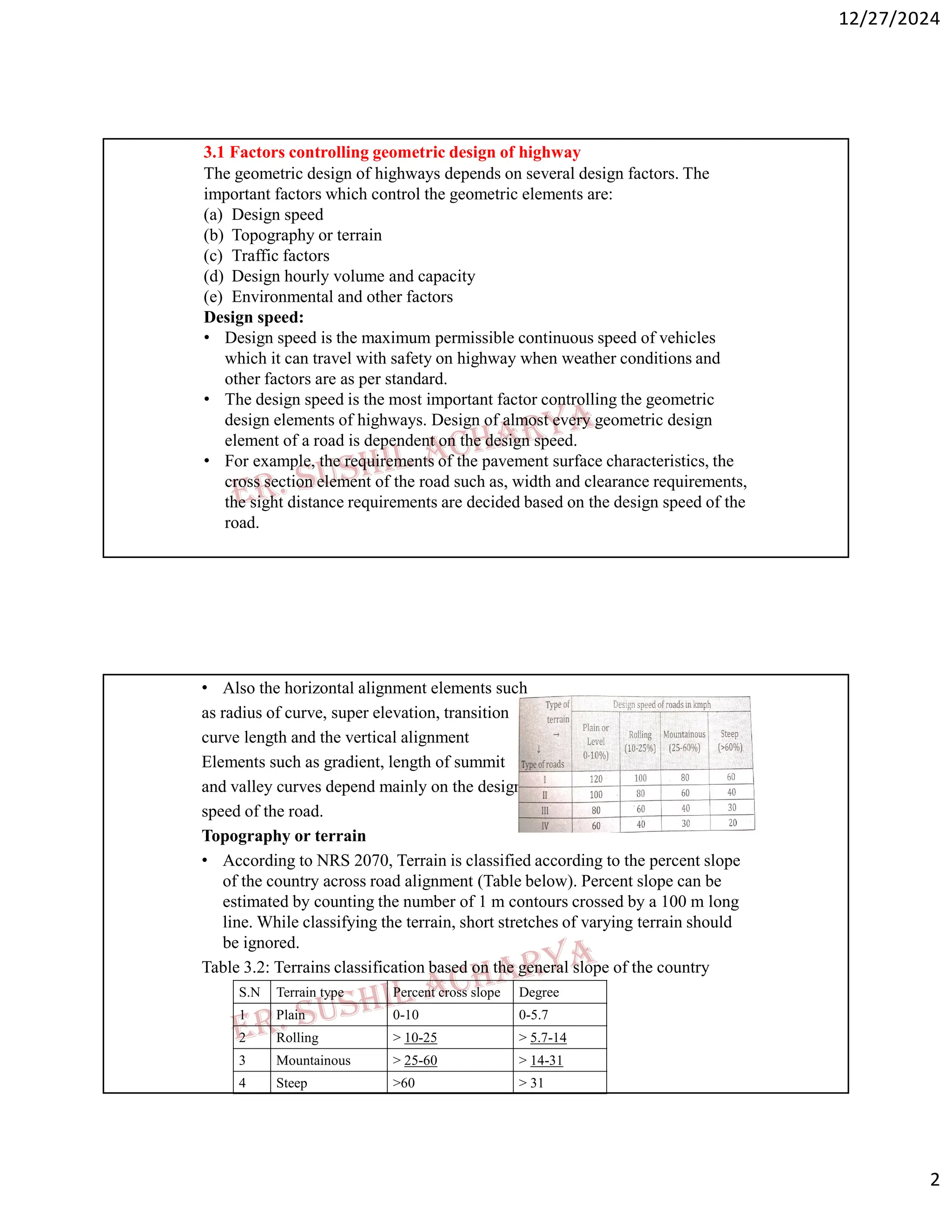

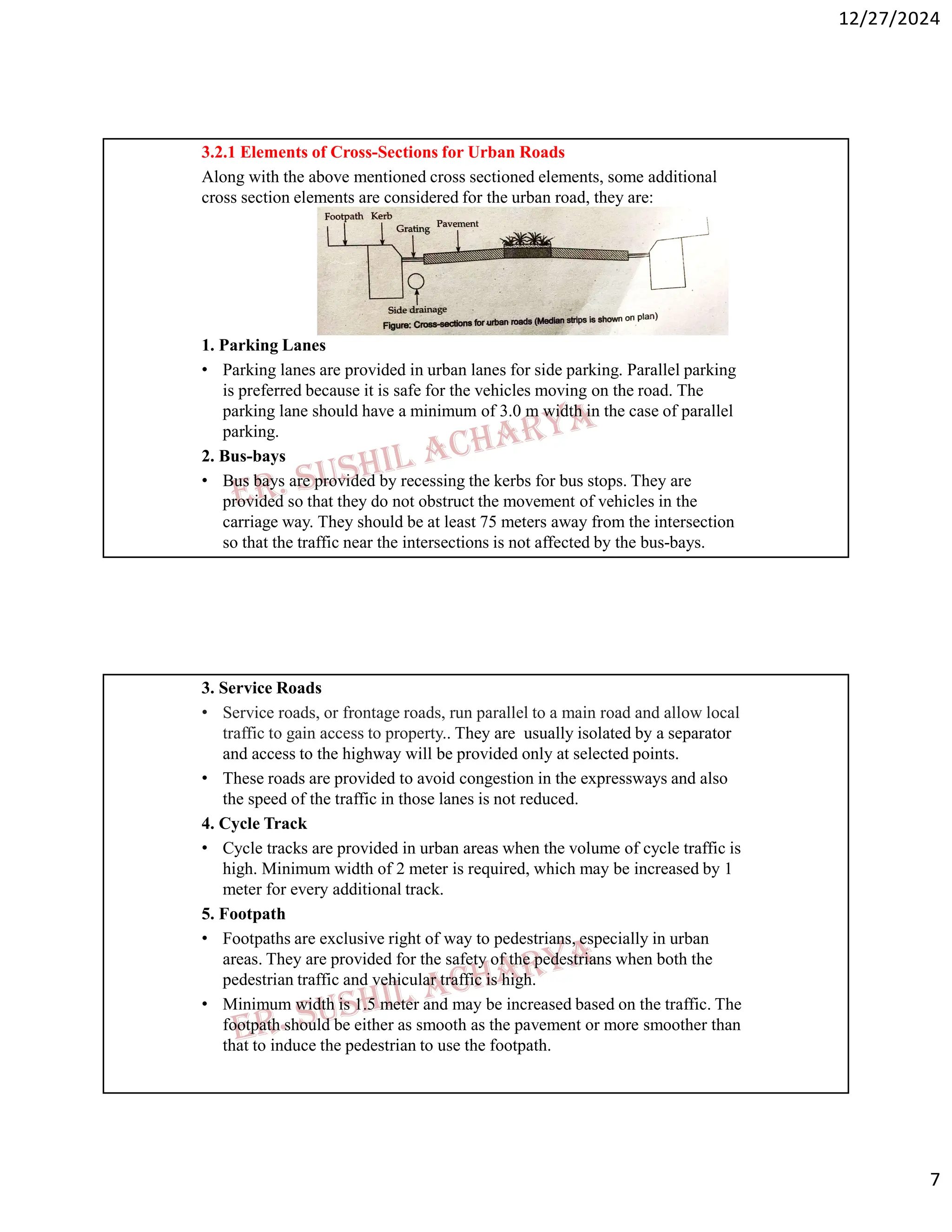

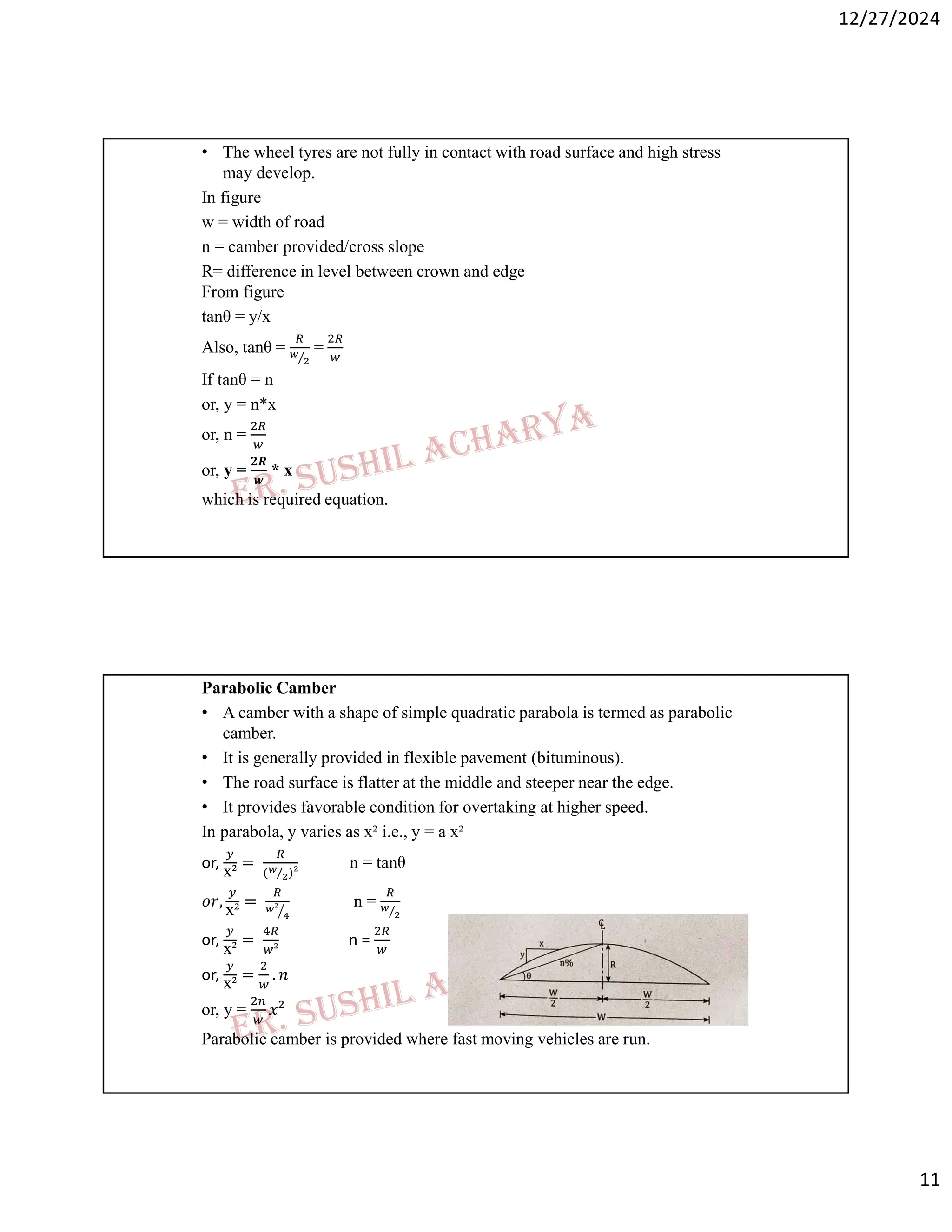

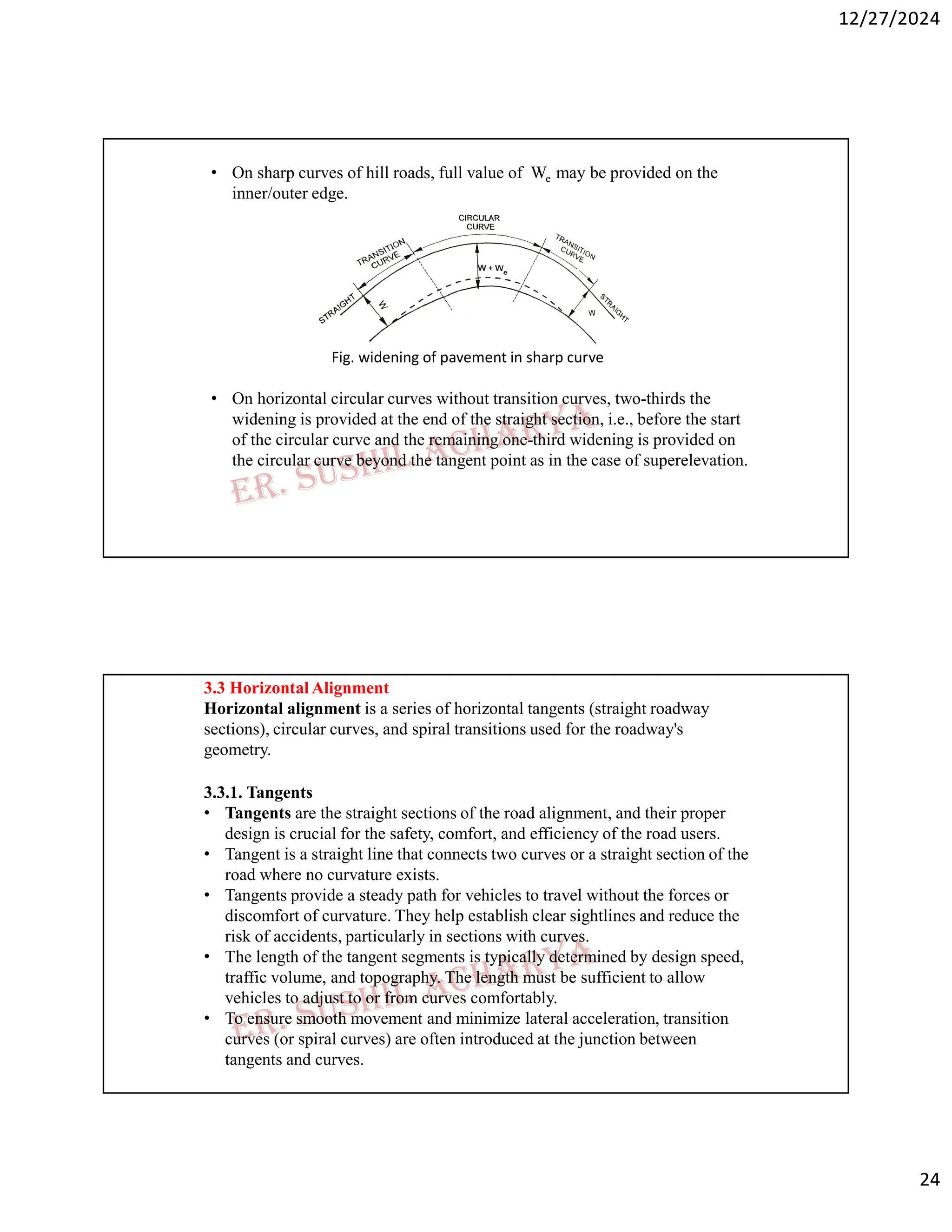

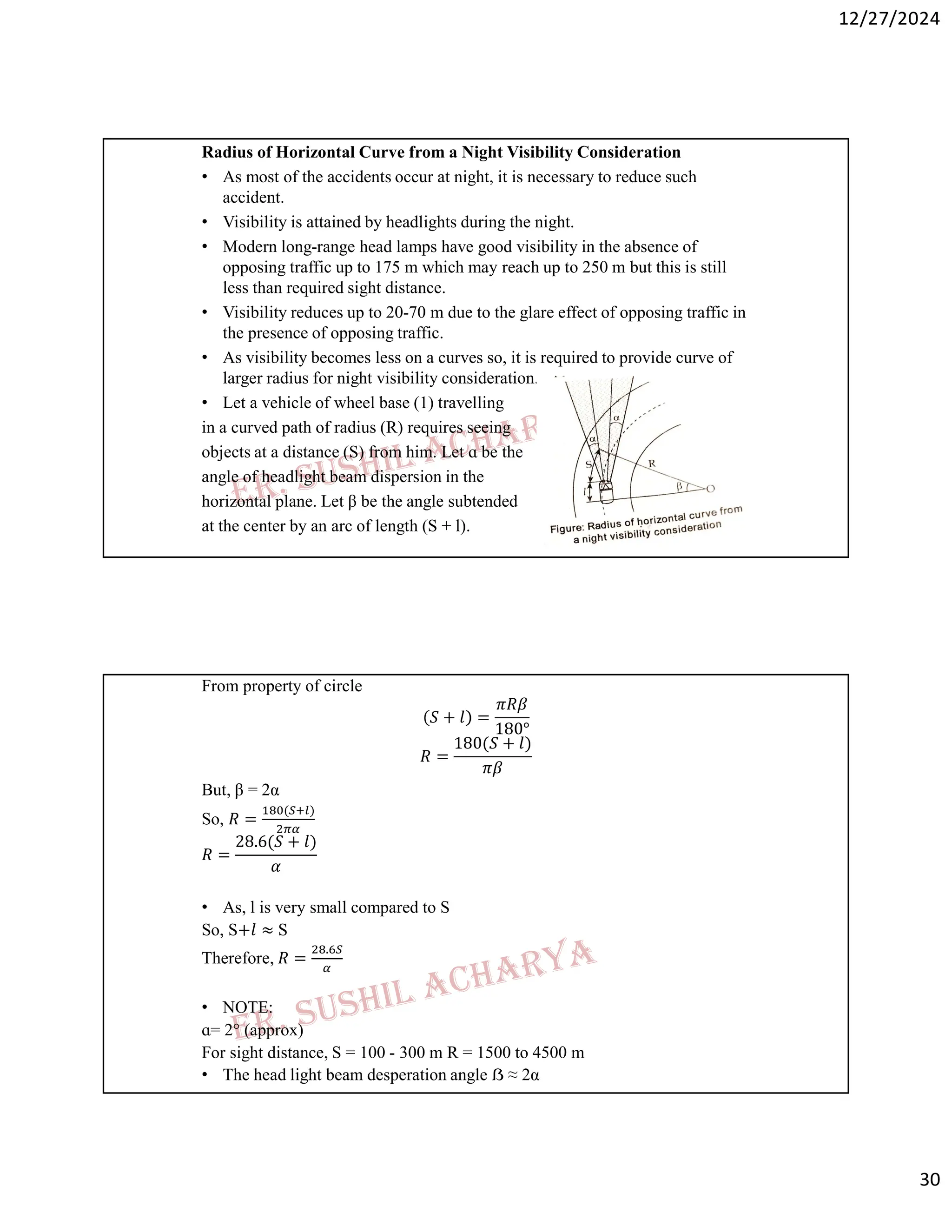

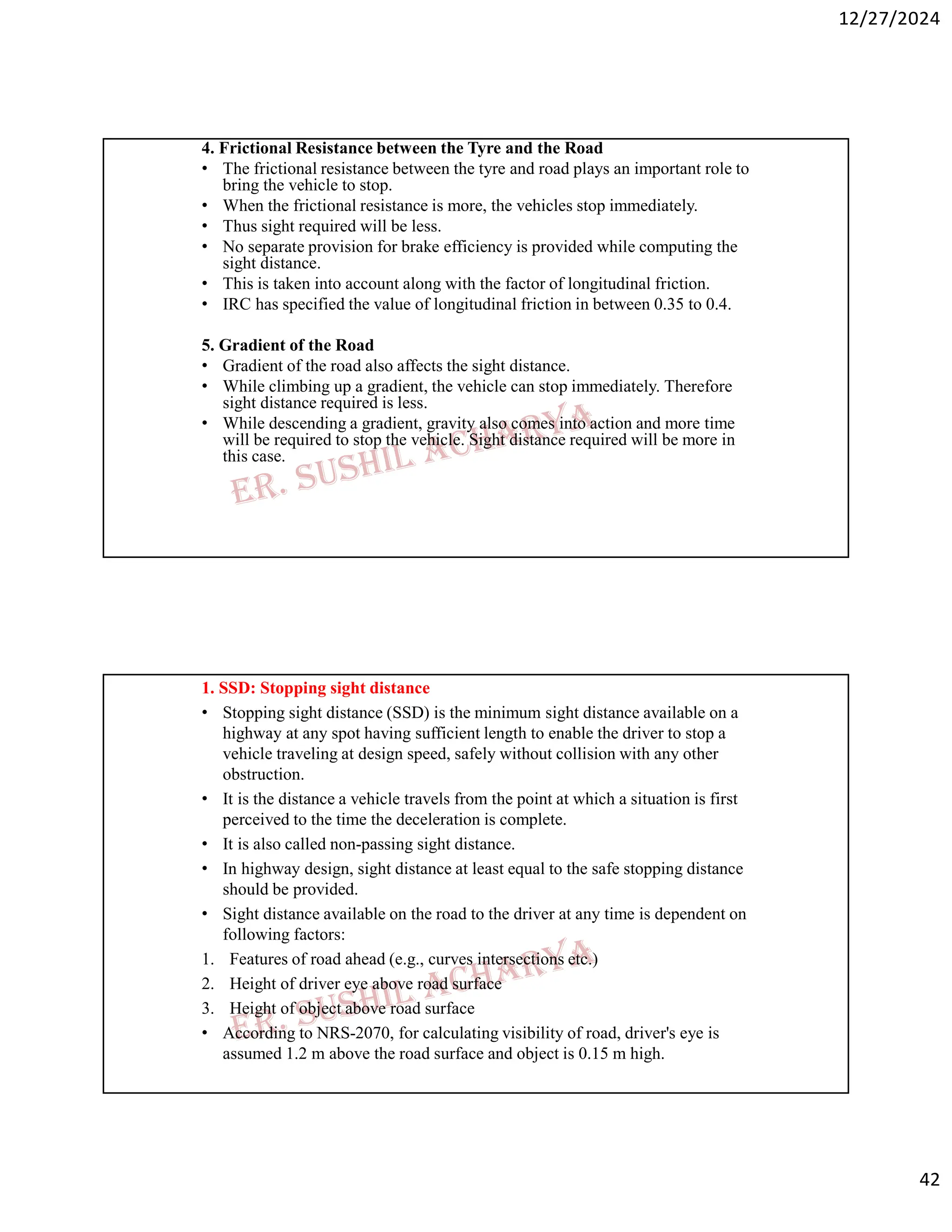

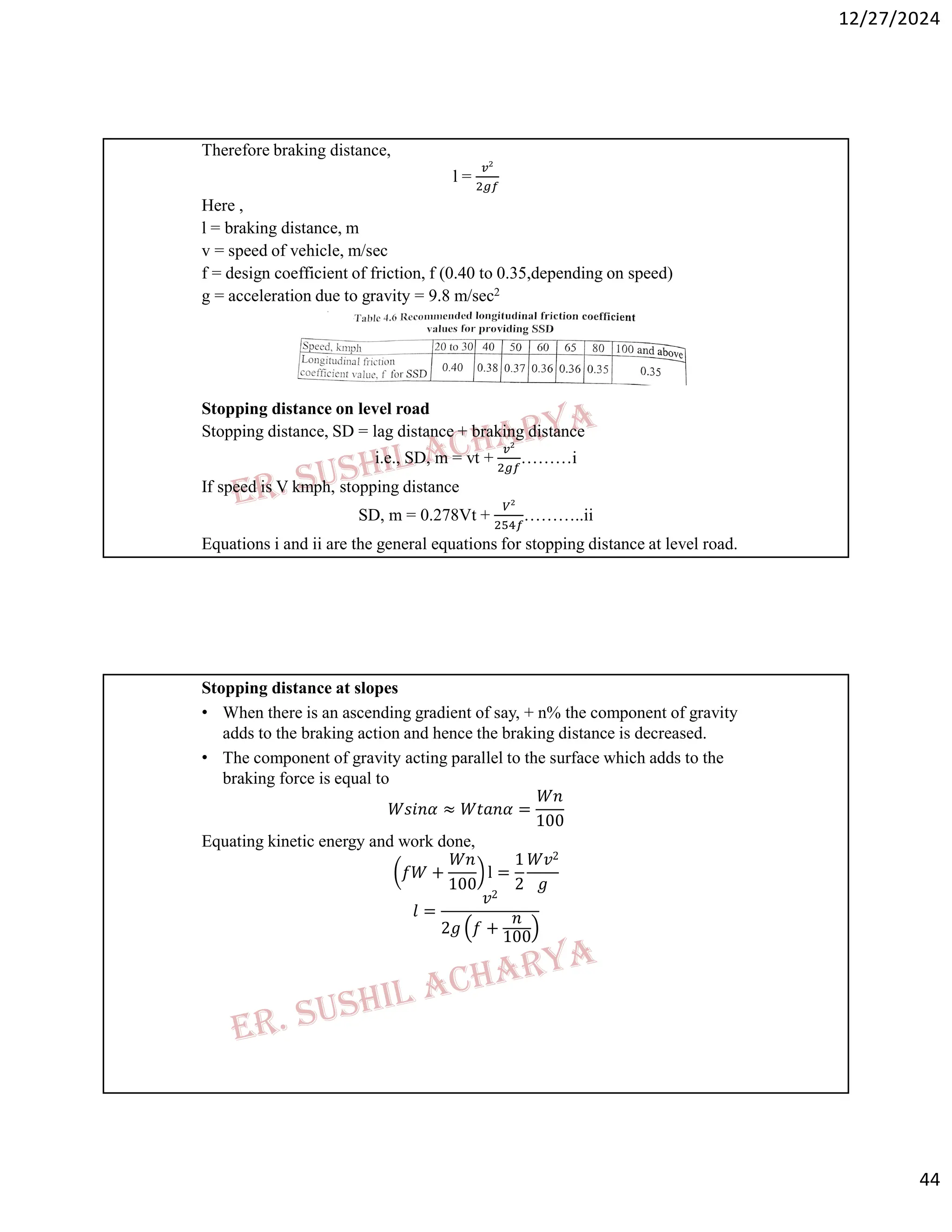

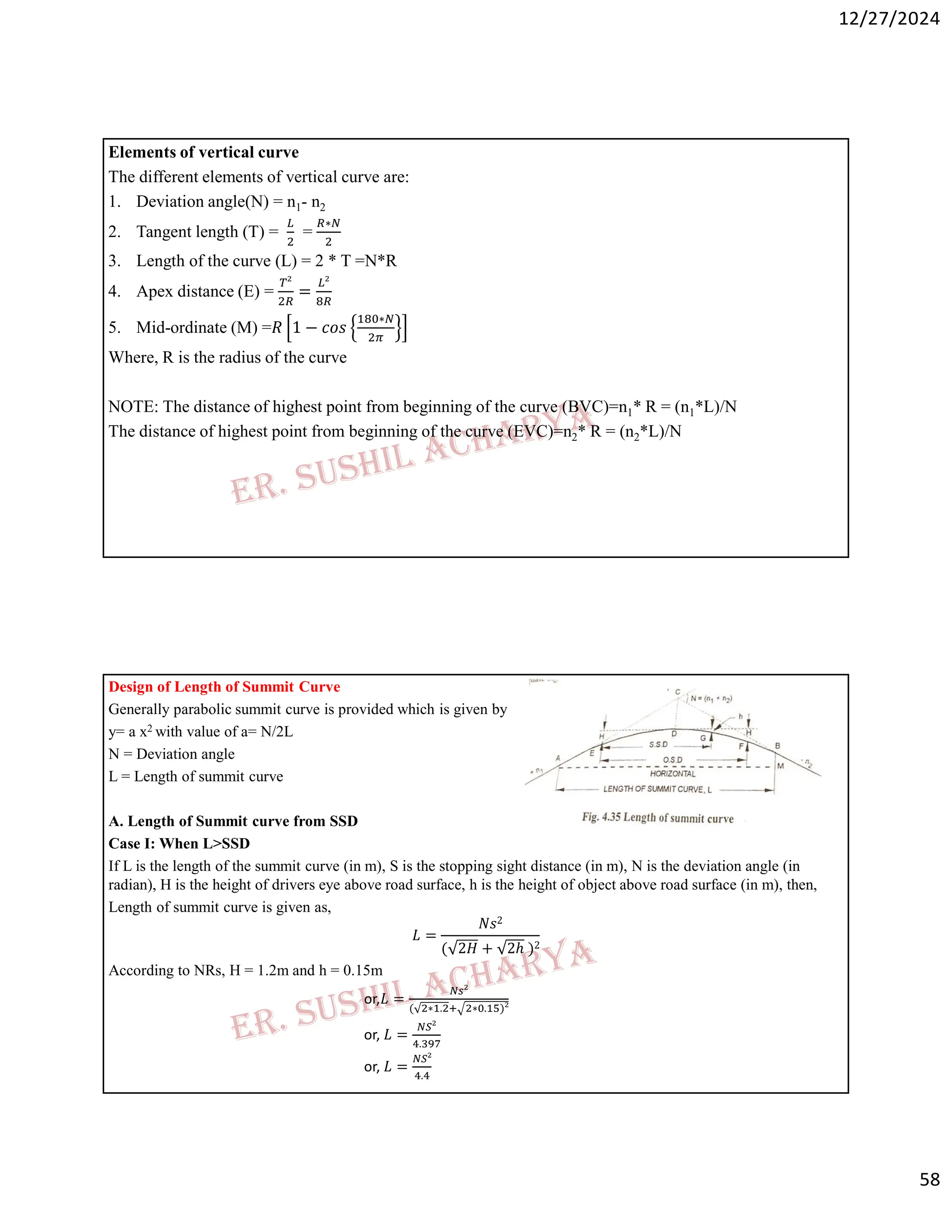

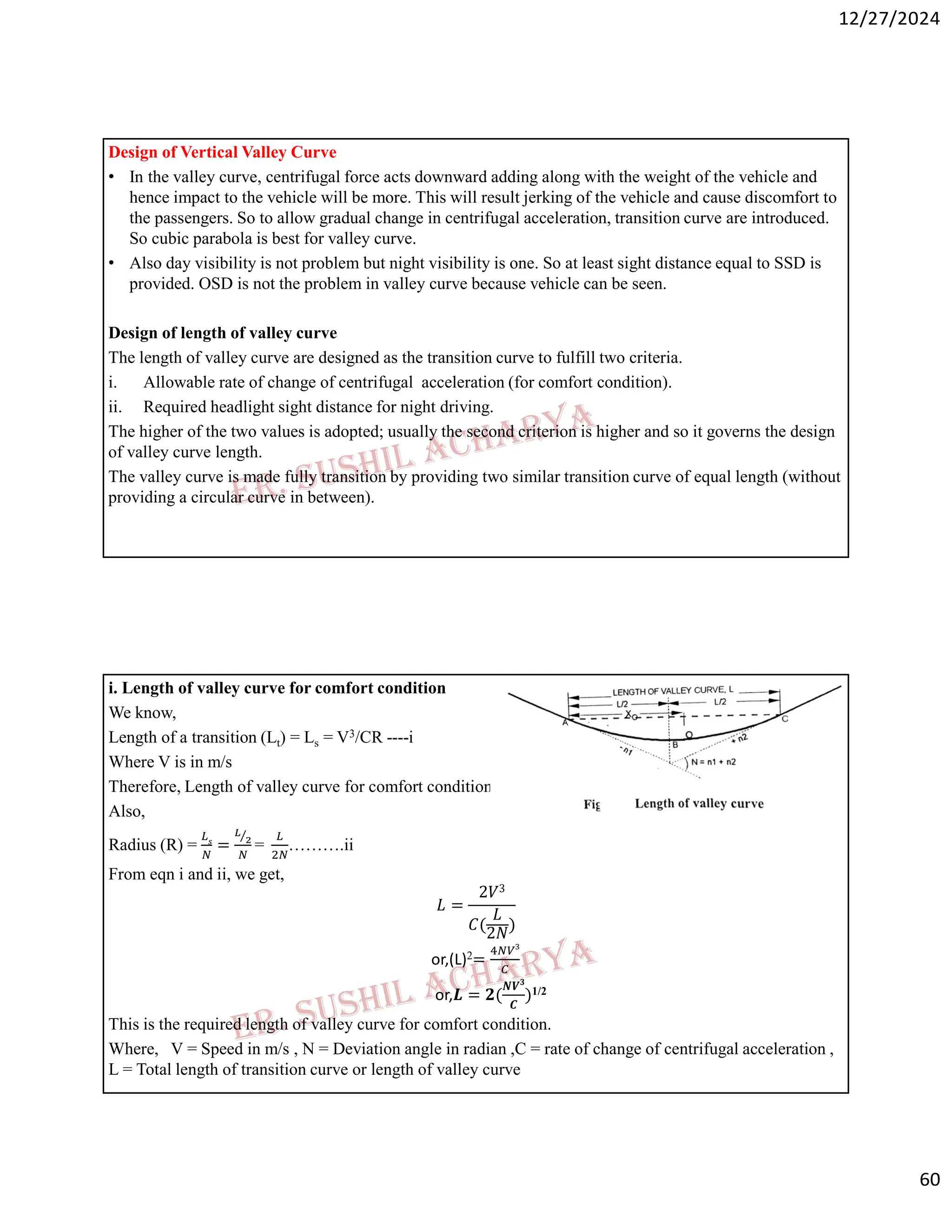

ii. Length of valley curve for headlight sight distance

Case a: When L>SSD

As we know,

Minimum sight distance is available when the vehicle

is at lowest point of valley curve. So length of

valley curve for this case is designed considering the

limiting condition. Considering parabolic vertical curve,

the equation is given as;

Y = ax2

Where a = N/2L

Therefore y = 𝑥2 ………….i

Let L be the length of valley curve h1 be the average height of head light and α be the beam angle, then,

At x = s , y = h1+stanα

So eqn i becomes,

ℎ1 + 𝑠𝑡𝑎𝑛𝛼 =

𝑁

2𝐿

∗ 𝑠2

ℎ1 + 𝑠𝑡𝑎𝑛𝛼

2𝐿

𝑠2

= 𝑁

𝐿 =

𝑁𝑠2

2[ℎ1 + 𝑠𝑡𝑎𝑛𝛼]

This is the equation for length of valley curve. Generally h1 = 0.75m and α = 1°

𝐿 =

𝑁𝑠2

2[0.75 + 𝑠𝑡𝑎𝑛1]

𝐿 =

𝑁𝑠2

2[0.75 + 0.0175]

𝑳 =

𝑵𝒔𝟐

𝟐[𝟏. 𝟓 + 𝟎. 𝟎𝟑𝟓𝟓]

Case b: When L<SSD

In this case the sight distance is minimum when the vehicle is at

the beginning of the valley curve.

In ∆CED

𝑡𝑎𝑛

𝑁

2

=

𝑠𝑡𝑎𝑛𝛼 + ℎ1

2

𝑆 − 𝐿/2

Or, 𝑡𝑎𝑛 =

/

here tan ≈](https://image.slidesharecdn.com/geo-second-last-250121143039-84a0dceb/75/geo-second-last-pdf-bbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbb-bggggggggggggggggggggggggg-61-2048.jpg)