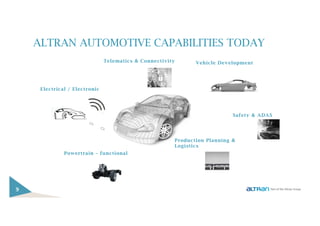

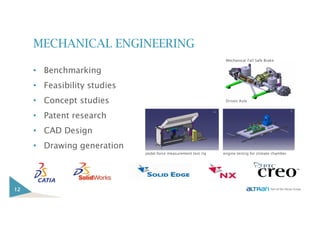

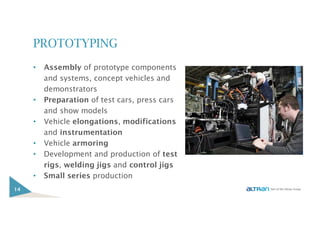

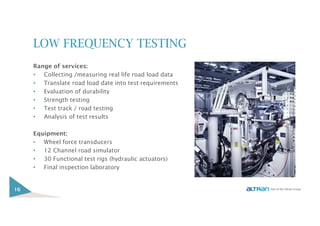

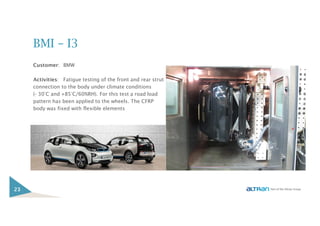

This document discusses Altran Engineering, a global engineering and R&D company with expertise in innovative product development, intelligent systems, lifecycle experience, and information systems. It provides an overview of Altran's operations in the Netherlands, including its history, offices, employees, clients, markets served, and capabilities. Examples of reference projects are also summarized for automotive, transportation, aerospace, energy, and other sectors.