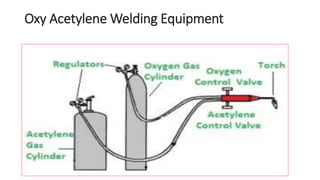

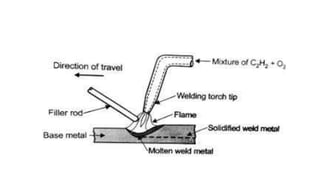

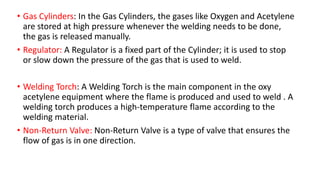

Gas welding involves burning a combustible gas like acetylene or hydrogen with oxygen to heat and melt metals for joining. Oxy-acetylene welding uses oxygen and acetylene gases to produce a flame reaching 3000-3500°C, melting a filler material and parent metals to join workpieces. Equipment includes gas cylinders, regulators, welding torches, and non-return valves. It has advantages of low cost, ability to weld various metals, and adjustable flame intensity, but disadvantages of lower temperature than arc welding and lack of flux shielding.