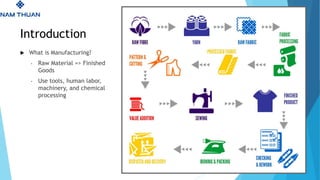

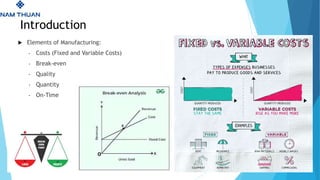

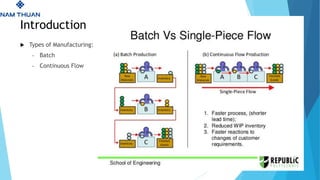

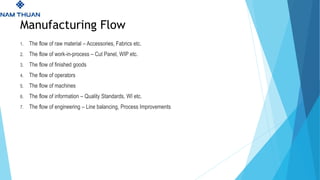

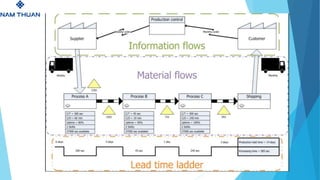

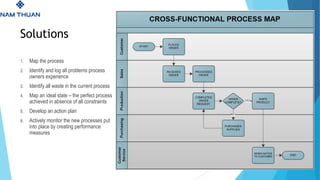

The document outlines the manufacturing process, highlighting the flow of raw materials to finished goods and the various types of manufacturing. It discusses barriers to flow, both physical and intangible, and provides solutions for improving manufacturing efficiency by mapping processes and identifying waste. An ideal state process is proposed, alongside an action plan for implementation and monitoring.