Embed presentation

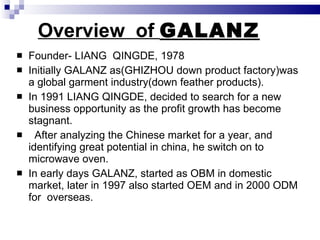

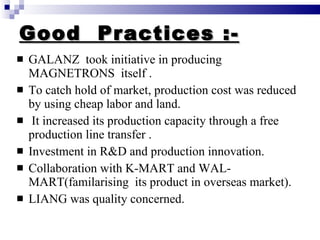

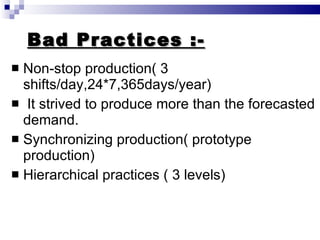

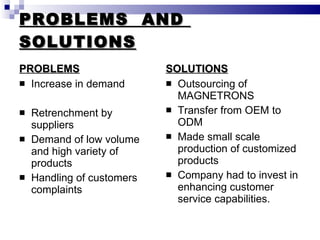

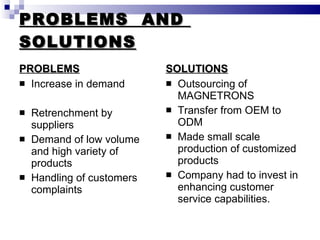

Galanz started as a garment manufacturer in 1978 but switched to producing microwave ovens in 1991 after identifying greater potential in the Chinese market. They took initiatives like producing their own magnetrons to reduce costs, increasing production capacity through transferring production lines, and investing in R&D and production innovation. They collaborated with large retailers to familiarize their products overseas. While their focus on low costs and high production led to issues like non-stop production and demand that exceeded forecasts, they solved problems like supplier retrenchment and customized demand through outsourcing, transitioning to an ODM model, and improving customer service.