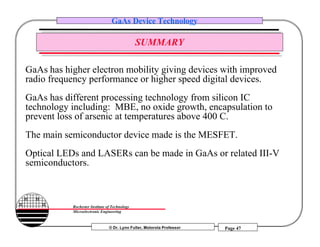

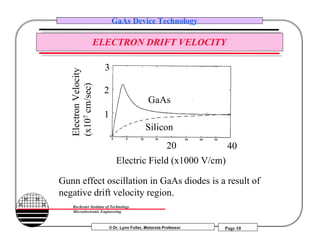

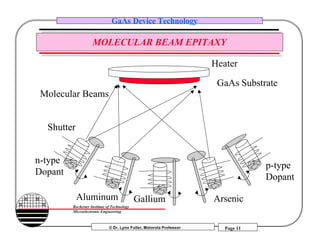

This document is a presentation by Dr. Lynn Fuller on Gallium Arsenide (GaAs) devices, technologies, and integrated circuits. It provides an overview and comparison of silicon and GaAs, describes GaAs crystal growth techniques like molecular beam epitaxy (MBE), and discusses GaAs field effect transistors (MESFETs) and the fabrication process for GaAs integrated circuits. The presentation contains numerous diagrams and equations to illustrate concepts in GaAs device physics and fabrication processes.

![© Dr. Lynn Fuller, Motorola Professor

Rochester Institute of Technology

Microelectronic Engineering

GaAs Device Technology

Page 18

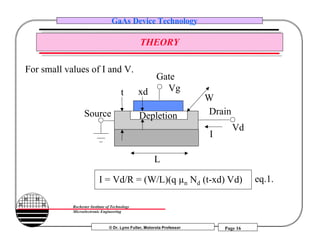

THEORY

Gate

Source Drain

L

Id

W

t xd

Vd

For larger values of I and V.

Depletion

Id = Go { V -2/3(2εs/qNdt2)0.5 [(Ψo-Vg+Vd)1.5 - (Ψo-Vg )1.5]}

Vg

eq. 2.](https://image.slidesharecdn.com/gaas-150924090435-lva1-app6891/85/Gaas-18-320.jpg)

![© Dr. Lynn Fuller, Motorola Professor

Rochester Institute of Technology

Microelectronic Engineering

GaAs Device Technology

Page 19

THEORY

Gate

Source Drain

L

Isat

W

t

Vd

For Pinch Off

Channel Pinched Off

Isat = Go [ qNd t2 - (Ψo-Vg ){1- 2/3[2εs (Ψo-Vg ) ]0.5}]

Depletion

Vg

qNdt26εs

eq. 3.](https://image.slidesharecdn.com/gaas-150924090435-lva1-app6891/85/Gaas-19-320.jpg)