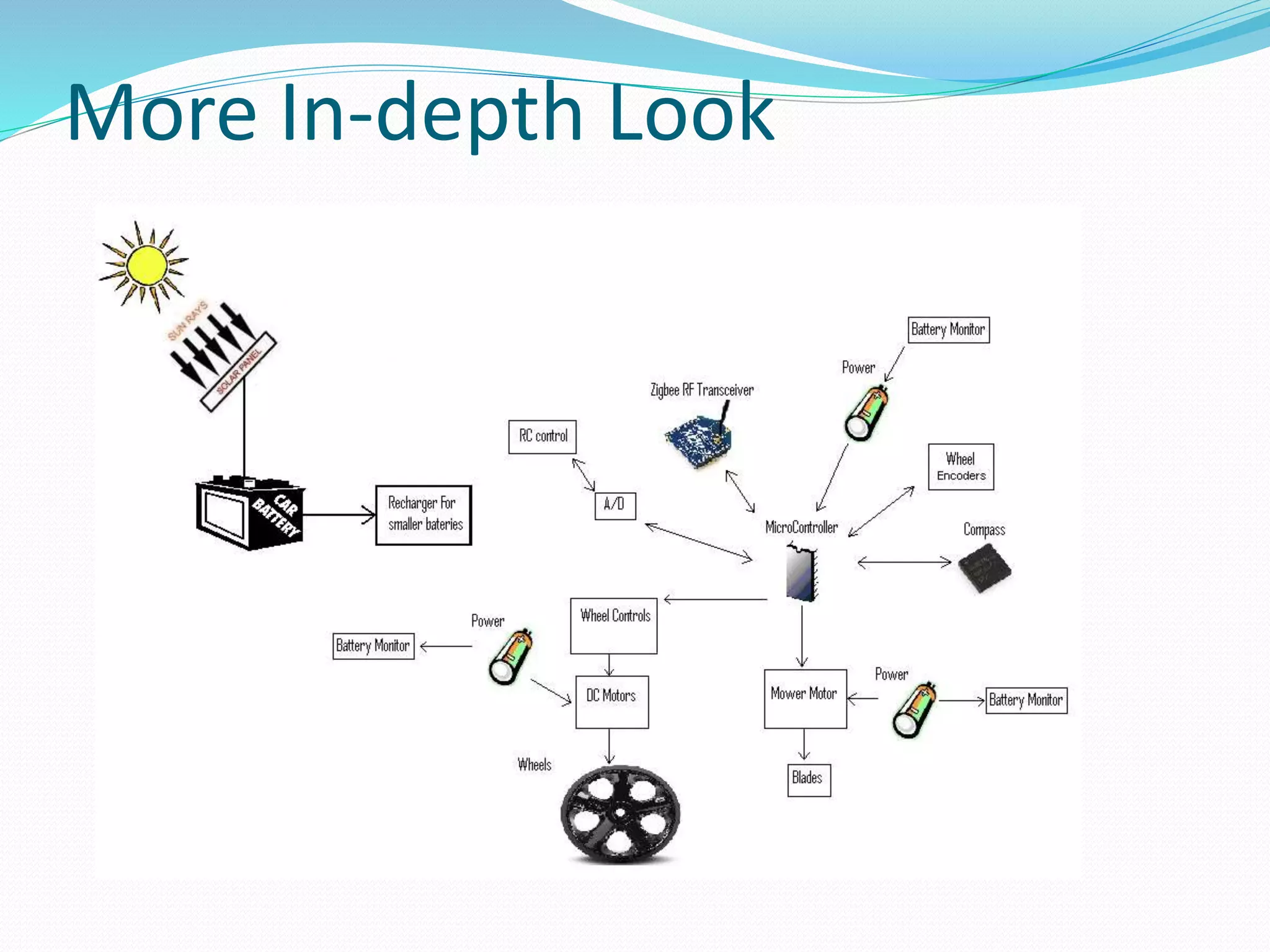

This document summarizes a project proposal for a fully automated solar-powered grass cutter. The grass cutter will be battery-powered and use solar charging. It will record a user's desired movement path and then autonomously replicate that path through AVR programming. The grass cutter will have wheels controlled by motors to move forward, backward, and turn. It will include interactions between the mower, solar charging station, and control unit. Potential applications include use in playgrounds, gardens, small farms, and nurseries. Risks include potential mechanical, motor, and electrical issues that would need to be addressed.