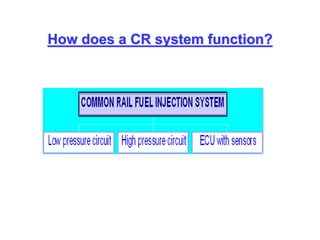

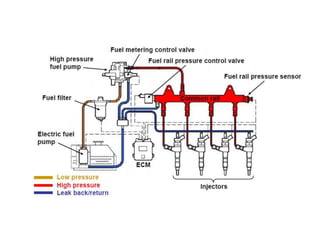

1. The common rail fuel injection system has low-pressure and high-pressure circuits to transport fuel and generate high injection pressures, controlled by an ECU and sensors.

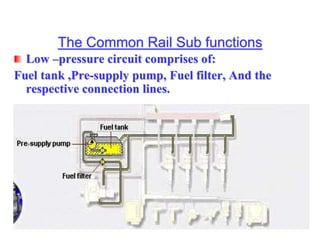

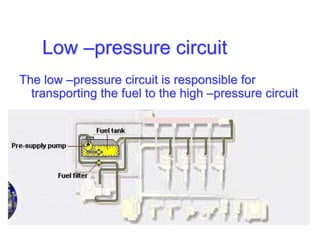

2. The low-pressure circuit cleans and moves fuel to the high-pressure circuit where a pump pressurizes the fuel up to 1,350 bar in a rail tank for storage.

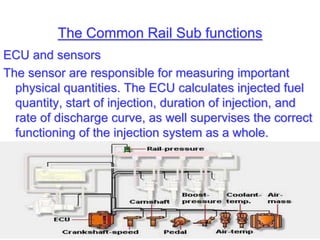

3. The ECU uses sensor readings to calculate injection values and trigger the injectors to inject precise amounts of fuel at optimal times from the constant-pressure rail tank.