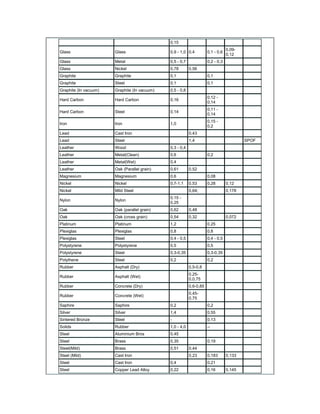

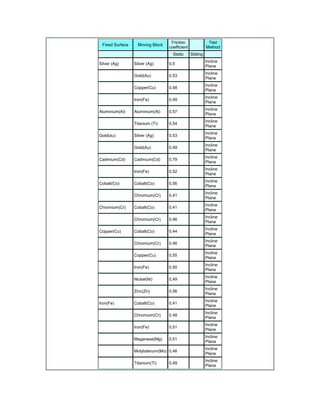

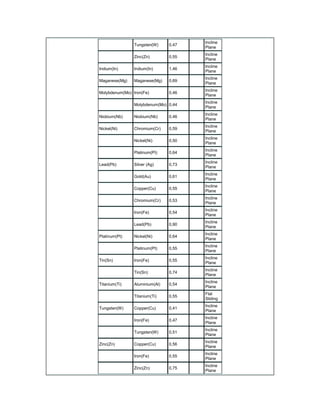

This document provides information on friction factors and coefficients of friction for various materials and configurations. It discusses factors that affect friction for both dry and lubricated surfaces. Tables with approximate coefficients are given for static friction, sliding friction, rolling friction, plain bearings, rolling bearings, bolted joints, power screws, and press fits. The document notes that friction values may vary depending on testing methods and conditions.