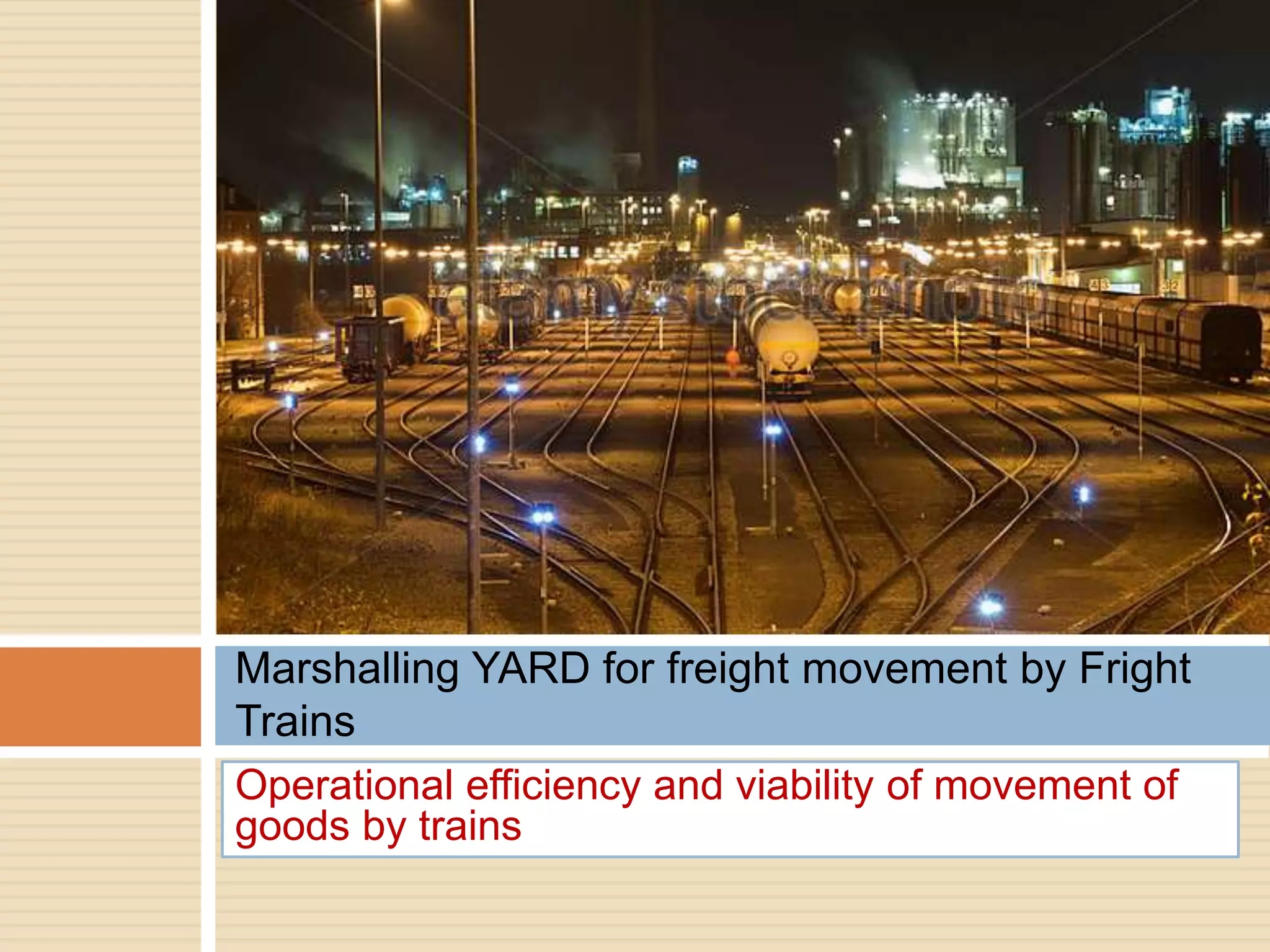

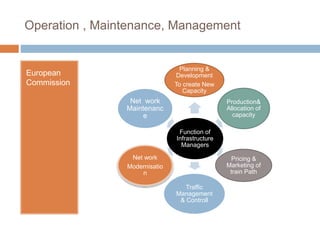

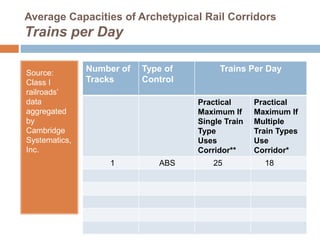

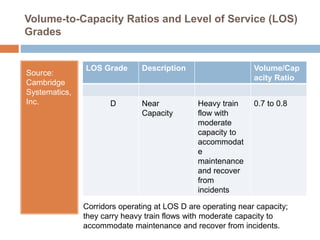

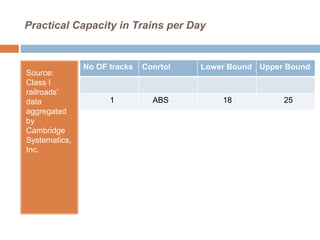

The document discusses the operational efficiency and viability of freight movement by trains, focusing on key performance indicators (KPIs) and productivity measures for railroads. It emphasizes the importance of technical and organizational improvements to enhance the rail freight market's profitability and capacity. Additionally, the document outlines how rail freight corridors are managed to ensure punctuality and traffic performance, while addressing factors that influence capacity.