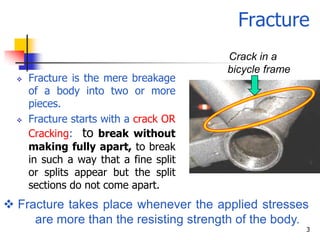

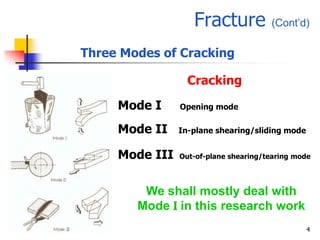

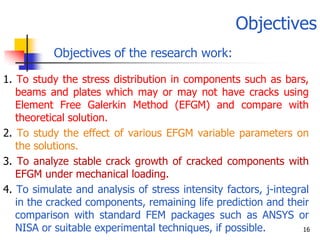

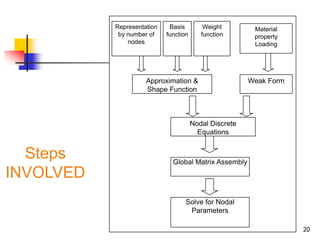

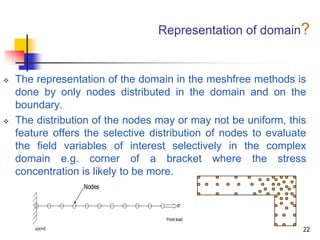

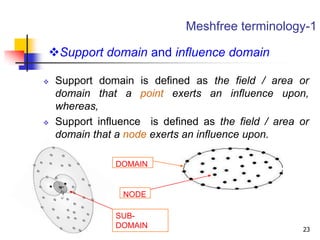

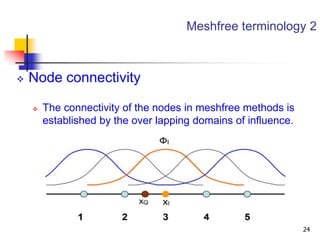

The document summarizes a presentation on fracture-fatigue simulation using meshfree methods. The objectives are to study stress distribution in cracked components using meshfree methods, analyze crack growth, and simulate stress intensity factors and J-integrals. Meshfree methods represent domains using nodes without elements, allowing selective node placement. They will be used to simulate fracture and fatigue crack propagation.