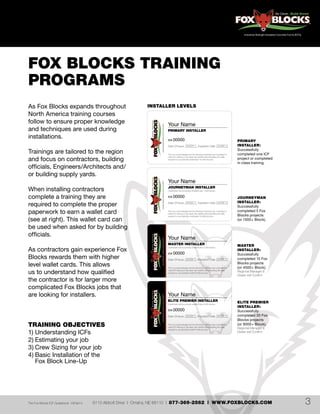

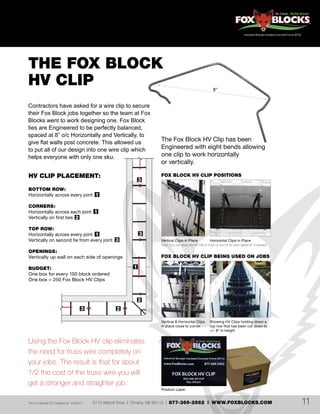

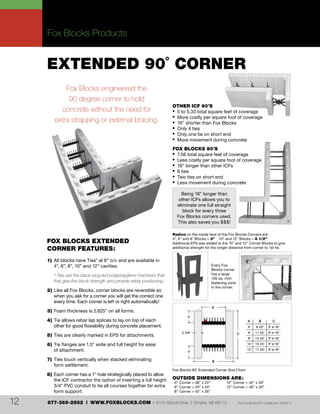

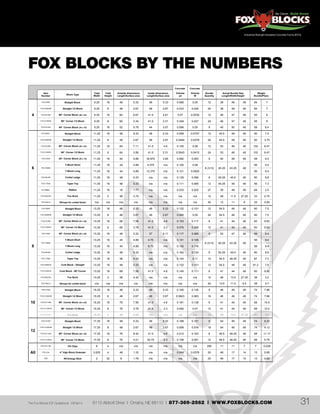

This document provides information about Fox Blocks insulated concrete forms (ICFs), including their training programs, product lineup, installation benefits, and estimating process. The training programs provide different certification levels as contractors gain experience. The product lineup includes straight blocks, corners, specialty pieces, and accessories. Key benefits are that the large interlocking system and extended corners eliminate the need for extra materials like truss wire or strapping. Contractors can save time and money on installations using Fox Blocks.