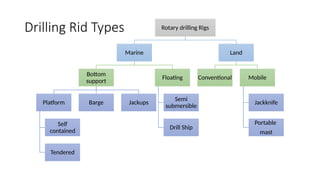

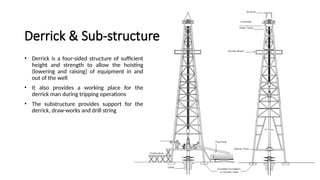

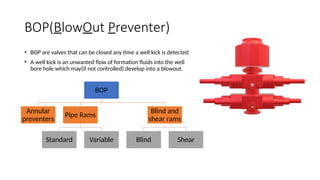

The document provides an overview of the micro, small, and medium enterprises (MSME) sector in India, emphasizing its significance in job creation and the training received from experts at MIT Pune. It details various types of drilling rigs, their components, and operational systems including rotary equipment, hoisting mechanisms, and circulation systems used in petroleum engineering. Additionally, it explains critical safety devices such as blowout preventers (BOP) that manage well kicks and prevent blowouts.