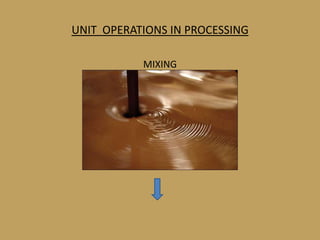

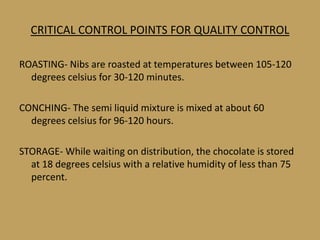

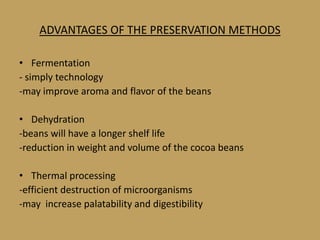

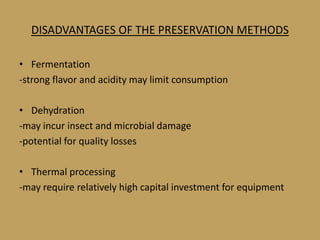

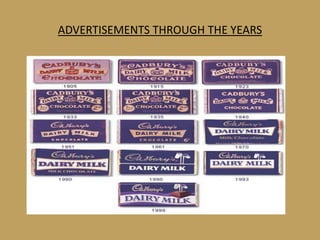

This document discusses the processing of chocolate. It describes the various unit operations involved such as sorting, splitting, fermentation, drying, bagging, winnowing, roasting, grinding, mixing, refining, conching, tempering, moulding and packaging. Critical control points like roasting and conching are identified. Preservation methods of fermentation, dehydration and thermal processing used in cocoa processing are discussed along with their advantages and disadvantages. Cadbury dairy milk chocolate storage, packaging, labeling and advertisements through the years are also outlined.