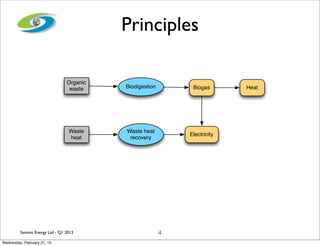

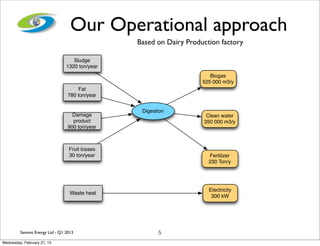

Sammo Energy proposes a solution for food industries to reduce costs by turning organic waste and waste heat into energy. They will fully fund and implement systems to generate power from biogas through digestion of organic waste and use waste heat. This will lower energy costs for industries through a long-term power purchase agreement without any investment needed from the industry. Sammo Energy will also manage programs to share benefits like carbon credits. Their approach involves surveying an industry's waste heat sources and organic waste to coordinate converting them into savings and revenue through technologies like organic Rankine cycle turbines and bio digestion.