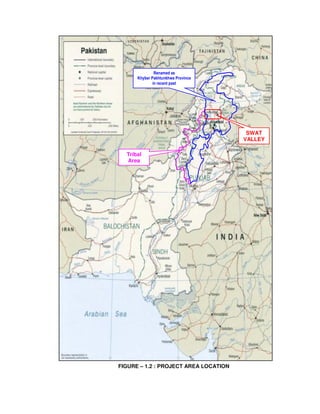

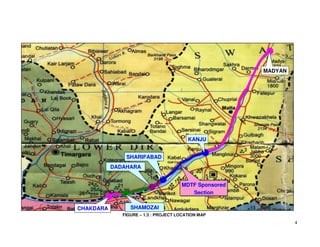

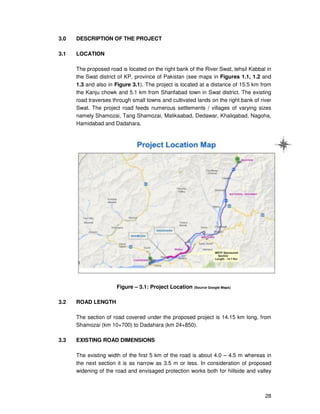

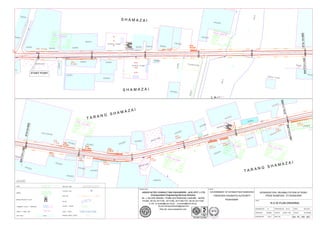

This document presents an environmental impact assessment for the proposed upgradation and rehabilitation of a road from Shamozai to Dadahara on the right bank of the Swat River in Khyber Pakhtunkhwa province, Pakistan. The project involves upgrading approximately 14.15 km of existing road to improve transportation in the area. An environmental and social assessment was conducted which included field surveys, consultation with local communities including women, and analysis of potential impacts. The assessment examines the existing physical, biological and social environment of the project area as well as applicable environmental regulations to identify issues and mitigate adverse effects of the road construction activities.

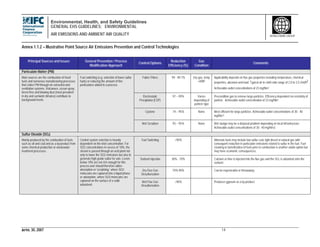

![Environmental, Health, and Safety Guidelines

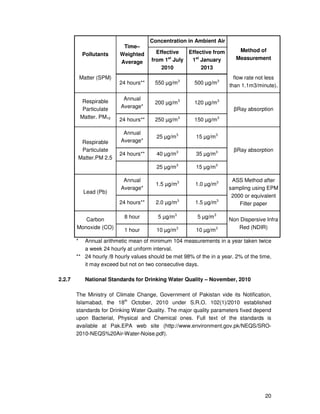

GENERAL EHS GUIDELINES: ENVIRONMENTAL

AIR EMISSIONS AND AMBIENT AIR QUALITY

APRIL 30, 2007 7

WORLD BANK GROUP

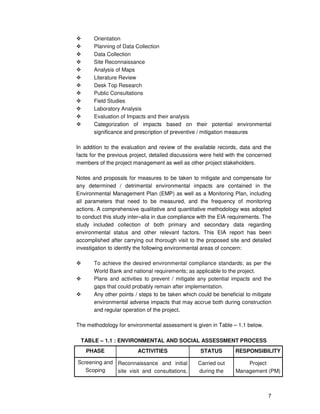

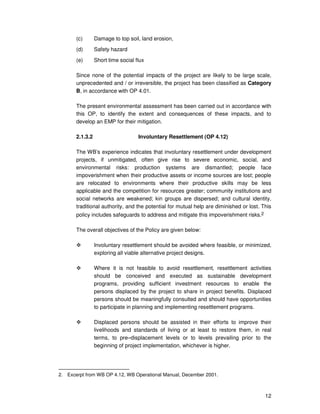

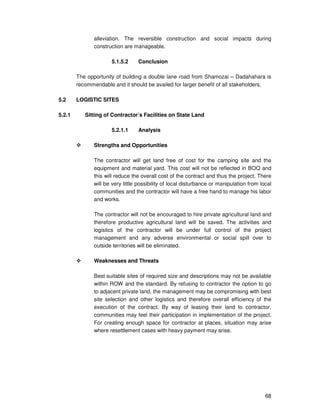

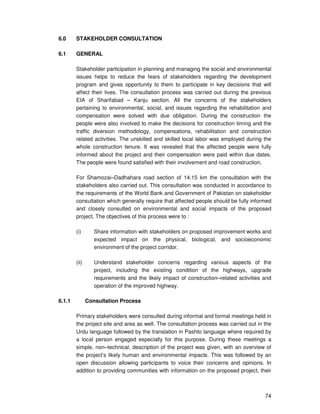

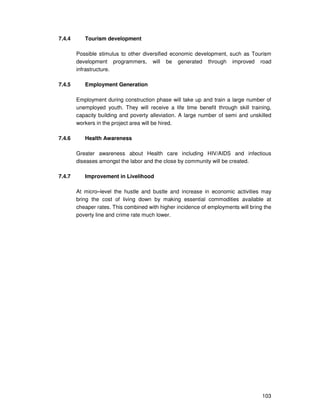

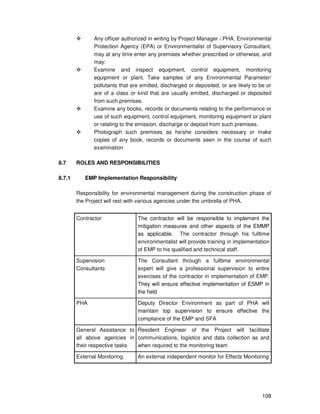

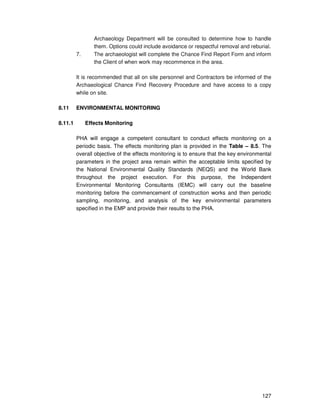

Table 1.1.2 - Small Combustion Facilities Emissions Guidelines (3MWth – 50MWth) – (in mg/Nm3 or as indicated)

Combustion Technology /

Fuel

Particulate Matter (PM) Sulfur Dioxide (SO2) Nitrogen Oxides (NOx)

Dry Gas, Excess

O2 Content (%)

Engine

Gas N/A N/A

200 (Spark Ignition)

400 (Dual Fuel)

1,600 (Compression Ignition)

15

Liquid

50 or up to 100 if justified by project specific

considerations (e.g. Economic feasibility of

using lower ash content fuel, or adding

secondary treatment to meet 50, and

available environmental capacity of the site)

1.5 percent Sulfur or up to 3.0 percent Sulfur if

justified by project specific considerations (e.g.

Economic feasibility of using lower S content fuel,

or adding secondary treatment to meet levels of

using 1.5 percent Sulfur, and available

environmental capacity of the site)

If bore size diameter [mm] < 400: 1460

(or up to 1,600 if justified to maintain high

energy efficiency.)

If bore size diameter [mm] > or = 400: 1,850

15

Turbine

Natural Gas

=3MWth to < 15MWth

N/A N/A

42 ppm (Electric generation)

100 ppm (Mechanical drive)

15

Natural Gas

=15MWth to < 50MWth

N/A N/A 25 ppm 15

Fuels other than Natural Gas

=3MWth to < 15MWth

N/A

0.5 percent Sulfur or lower percentSulfur (e.g. 0.2

percent Sulfur) if commercially available without

significant excess fuel cost

96 ppm (Electric generation)

150 ppm (Mechanical drive)

15

Fuels other than Natural Gas

=15MWth to < 50MWth

N/A

0.5% S or lower % S (0.2%S) if commercially

available without significant excess fuel cost

74 ppm 15

Boiler

Gas N/A N/A 320 3

Liquid

50 or up to 150 if justified by environmental

assessment

2000 460 3

Solid

50 or up to 150 if justified by environmental

assessment

2000 650 6

Notes: -N/A/ - no emissions guideline;Higher performance levels than these in the Table should be applicable to facilities located in urban / industrial areas with degraded airsheds or close to ecologically sensitive areas where more

stringent emissions controls may be needed.; MWth is heat input on HHV basis; Solid fuels include biomass; Nm3 is at one atmosphere pressure, 0°C.; MWth category is to apply to the entire facility consisting of multiple units that are

reasonably considered to be emitted from a common stack except for NOx and PM limits for turbines and boilers. Guidelines values apply to facilities operating more than 500 hours per year with an annual capacity utilization factor of

more than 30 percent.](https://image.slidesharecdn.com/finalizedeiashamozai-dadahara12-151027101757-lva1-app6891/85/Finalized-eia-shamozai-dadahara-12-12-2013-175-320.jpg)

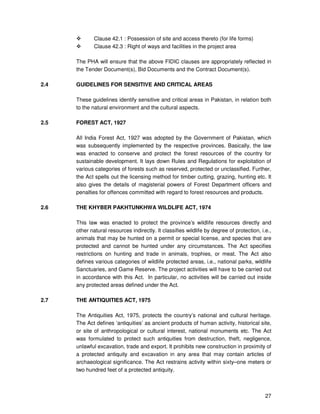

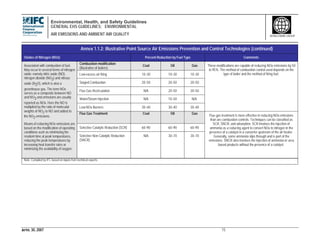

![Environmental, Health, and Safety (EHS) Guidelines

GENERAL EHS GUIDELINES: COMMUNITY HEALTH AND SAFETY

APRIL 30, 2007 81

WORLD BANK GROUP

meets the requirements of these L&FS guidelines. The

findings and recommendations of the review are then used to

establish the conditions of a Corrective Action Plan and a

time frame for implementing the changes.

• The suitably qualified professional conducts a review as part

of the project completion test at the time of life and fire safety

systems testing and commissioning, and certifies that

construction of these systems has been carried out in

accordance with the accepted design. The findings and

recommendations of the review are used as the basis for

establishing project completion or to establish the conditions

of a Pre-Completion Corrective Action Plan and a time frame

for implementing the changes.

Specific Requirements for Existing

Buildings

• All life and fire safety guideline requirements for new

buildings apply to existing buildings programmed for

renovation. A suitably qualified professional conducts a

complete life and fire safety review of existing buildings

slated for renovation. The findings and recommendations of

the review are used as the basis to establish the scope of

work of a Corrective Action Plan and a time frame for

implementing the changes.

• If it becomes apparent that life and fire safety conditions are

deficient in an existing building that is not part of the project

or that has not been programmed for renovation, a life and

fire safety review of the building may be conducted by a

suitably qualified professional. The findings and

recommendations of the review are used as the basis to

establish the scope of work of a Corrective Action Plan and a

time frame for implementing the changes.

Other Hazards

• Facilities, buildings, plants, and structures should be situated

to minimize potential risks from forces of nature (e.g.

earthquakes, tsunamis, floods, windstorms, and fires from

surrounding areas).

• All such structures should be designed in accordance with

the criteria mandated by situation-, climatic-, and geology-

specific location risks (e.g. seismic activity, wind loading, and

other dynamic loads).

• Structural engineers and architects responsible for facilities,

buildings, plants and structures should certify the applicability

and appropriateness of the design criteria employed.

• National or regional building regulations typically contain fire

safety codes and standards83 or these standards are found in

separate Fire Codes.84,85 Generally, such codes and

regulations incorporate further compliance requirements with

respect to methodology, practice, testing, and other codes

and standards86. Such nationally referenced material

constitutes the acceptable fire life safety code.

3.4 Traffic Safety

Traffic accidents have become one of the most significant causes

of injuries and fatalities among members of the public worldwide.

Traffic safety should be promoted by all project personnel during

displacement to and from the workplace, and during operation of

project equipment on private or public roads. Prevention and

control of traffic related injuries and fatalities should include the

adoption of safety measures that are protective of project workers

and of road users, including those who are most vulnerable to

road traffic accidents87. Road safety initiatives proportional to the

scope and nature of project activities should include:

83 For example, Australia, Canada, South Africa, United Kingdom

84 Réglementation Incendie [des ERP]

85 USA NFPA, 2006.

86 Prepared by National Institutes and Authorities such as American Society for

Testing and Materials (ASTM), British Standards (BS), German Institute of

Standardization (DIN), and French Standards (NF)

87 Additional information on vulnerable users of public roads in developing

countries is provided by Peden et al., 2004.](https://image.slidesharecdn.com/finalizedeiashamozai-dadahara12-151027101757-lva1-app6891/85/Finalized-eia-shamozai-dadahara-12-12-2013-249-320.jpg)