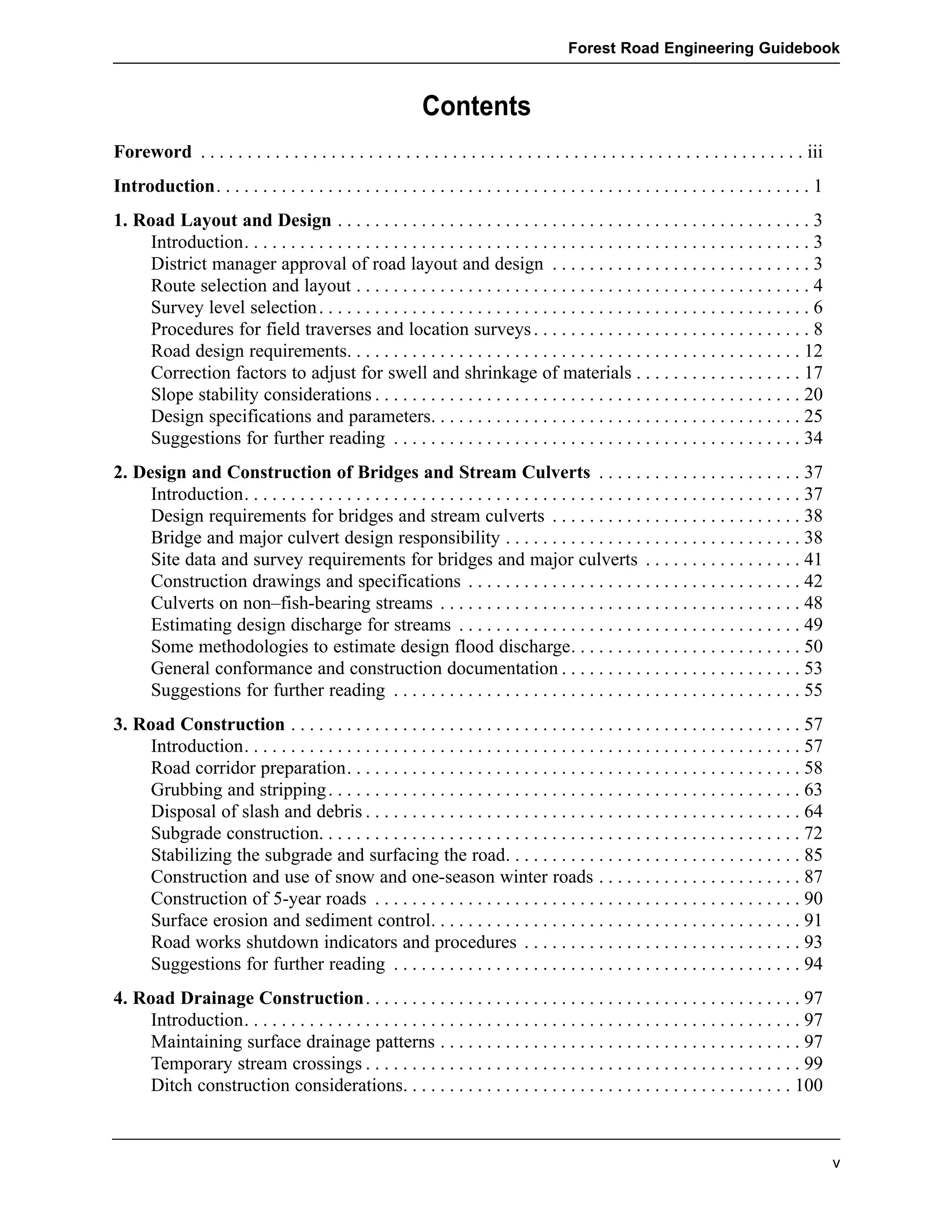

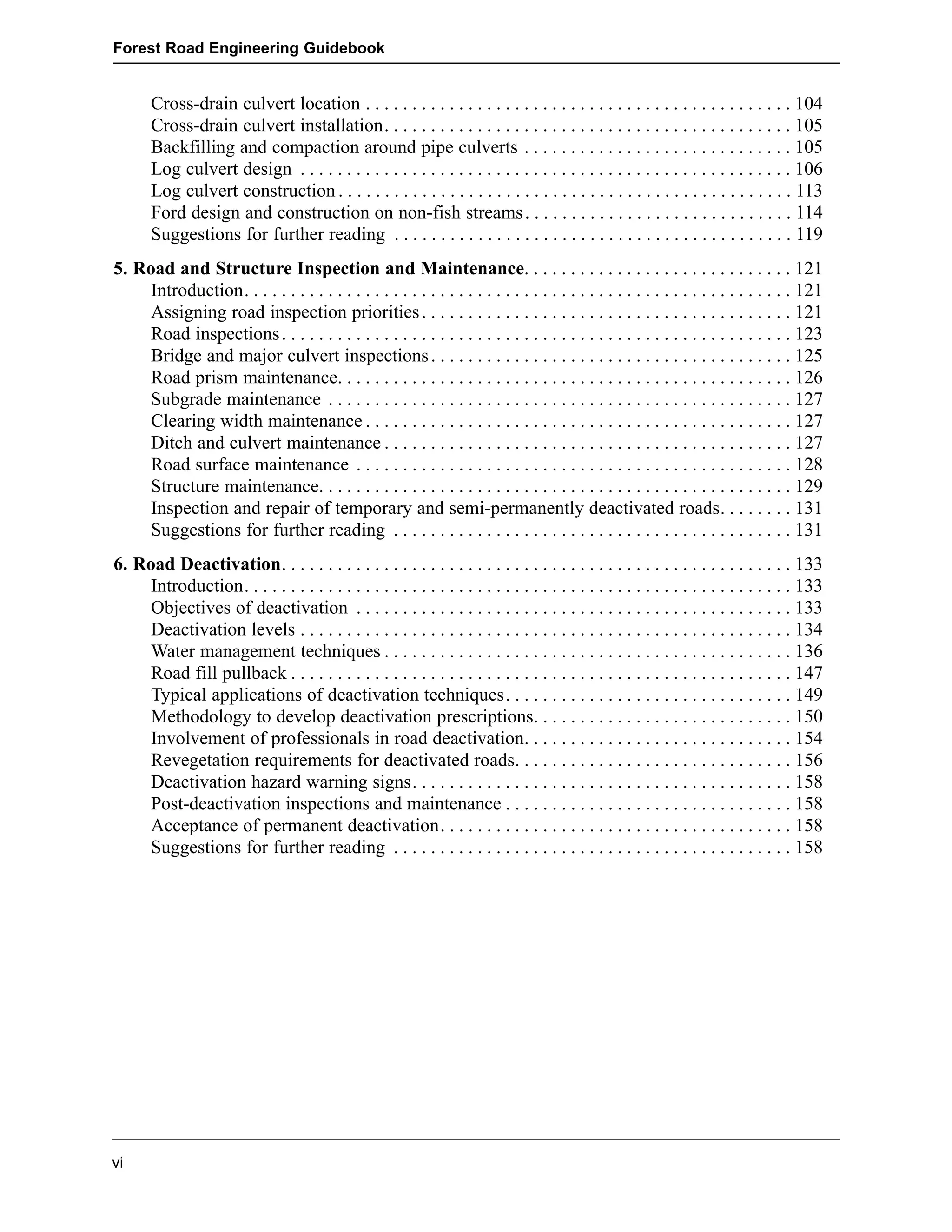

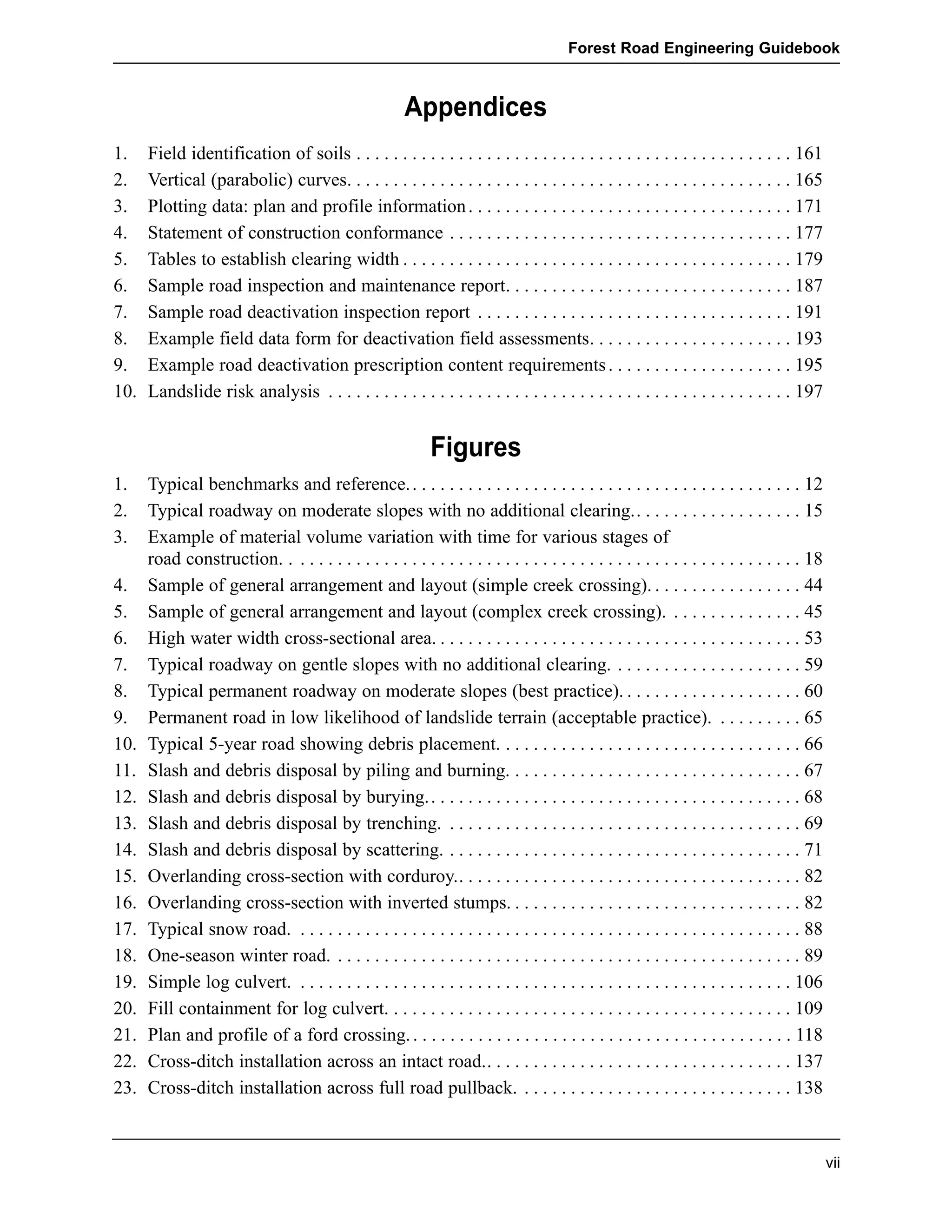

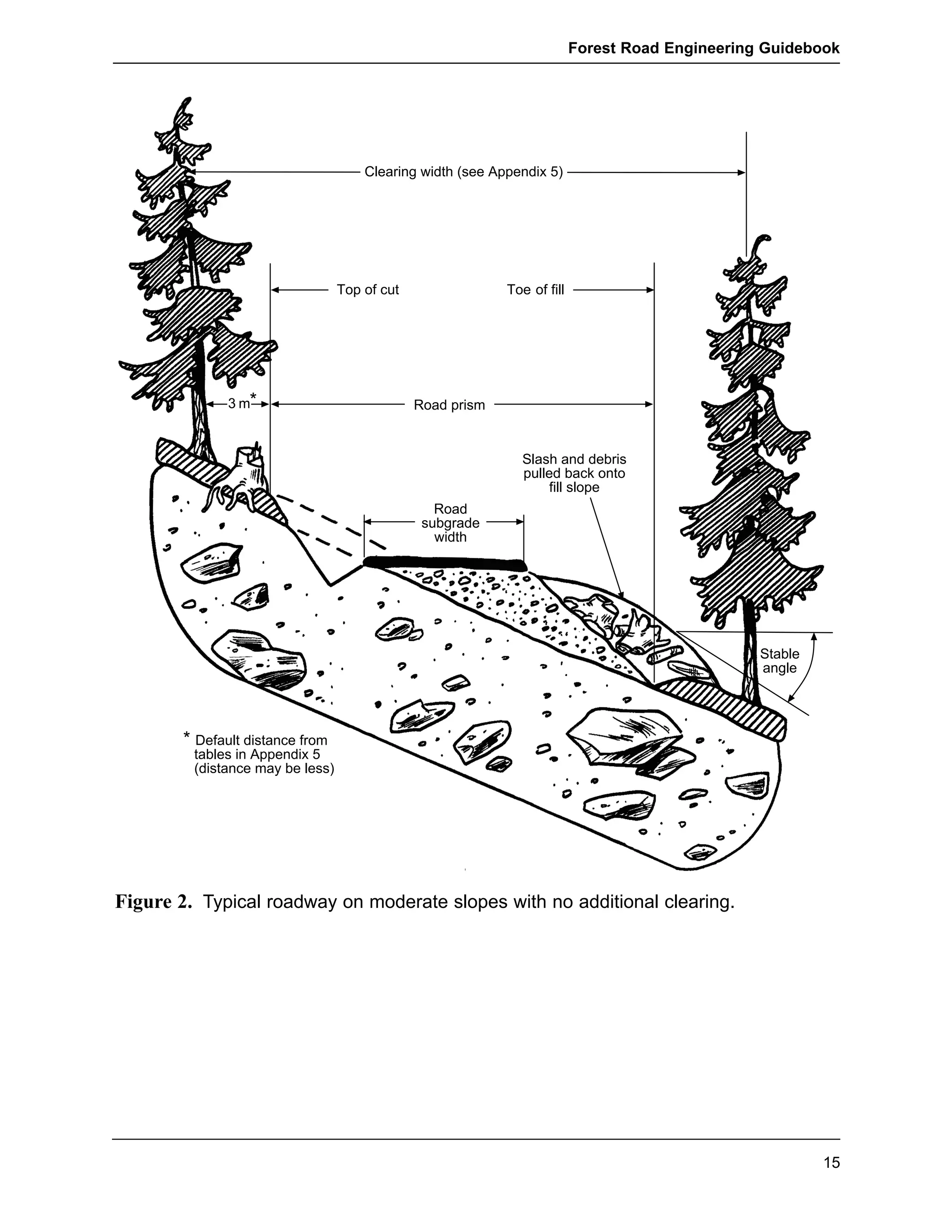

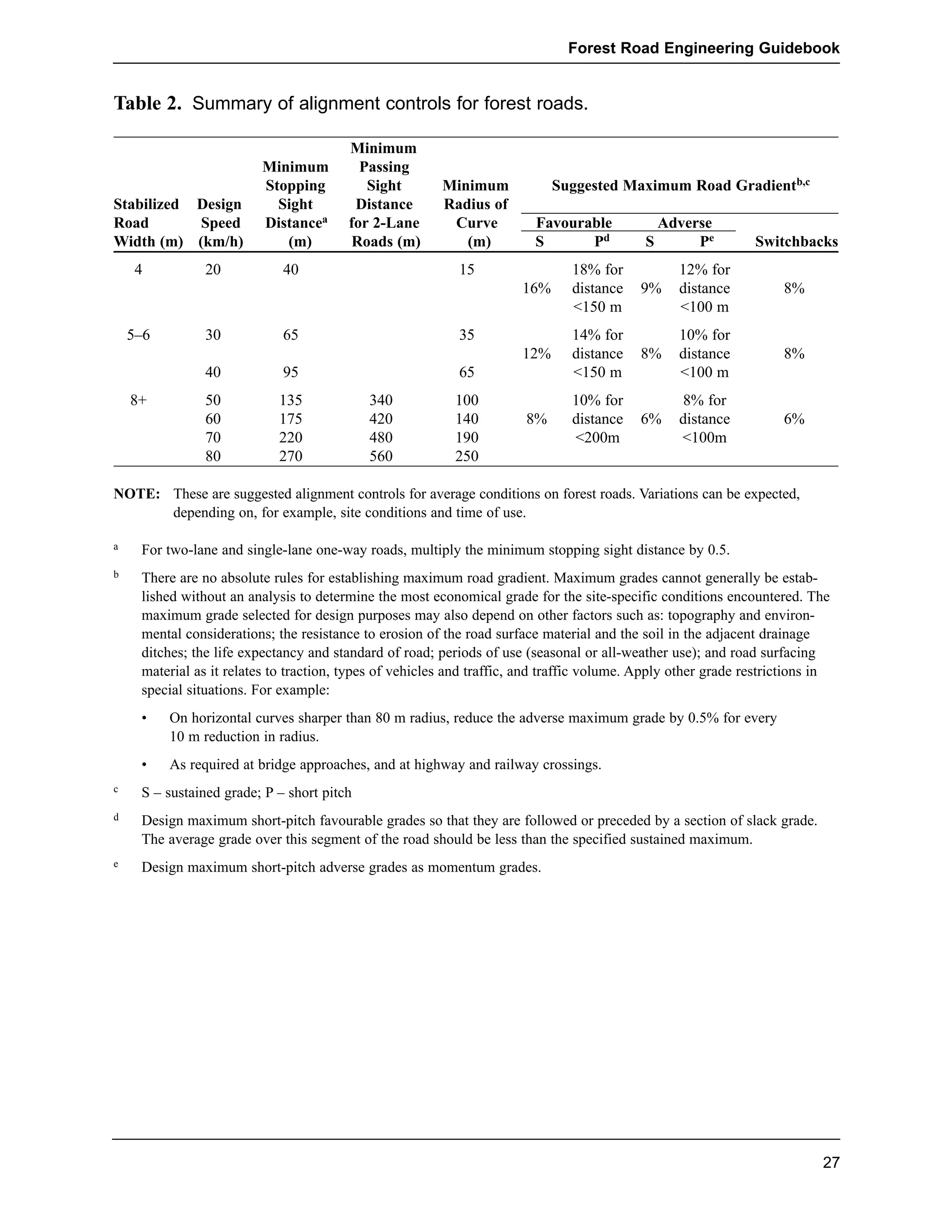

This document is the Forest Road Engineering Guidebook published by the Ministry of Forests of British Columbia. It provides guidance on road design, construction, drainage, inspection and maintenance to help forest practitioners meet the requirements of the Forest Practices Code. The guidebook covers topics such as route selection, surveys, design specifications, bridge and culvert design, road construction techniques, drainage structures, and road inspection and maintenance best practices. It is intended as advice rather than mandatory requirements.