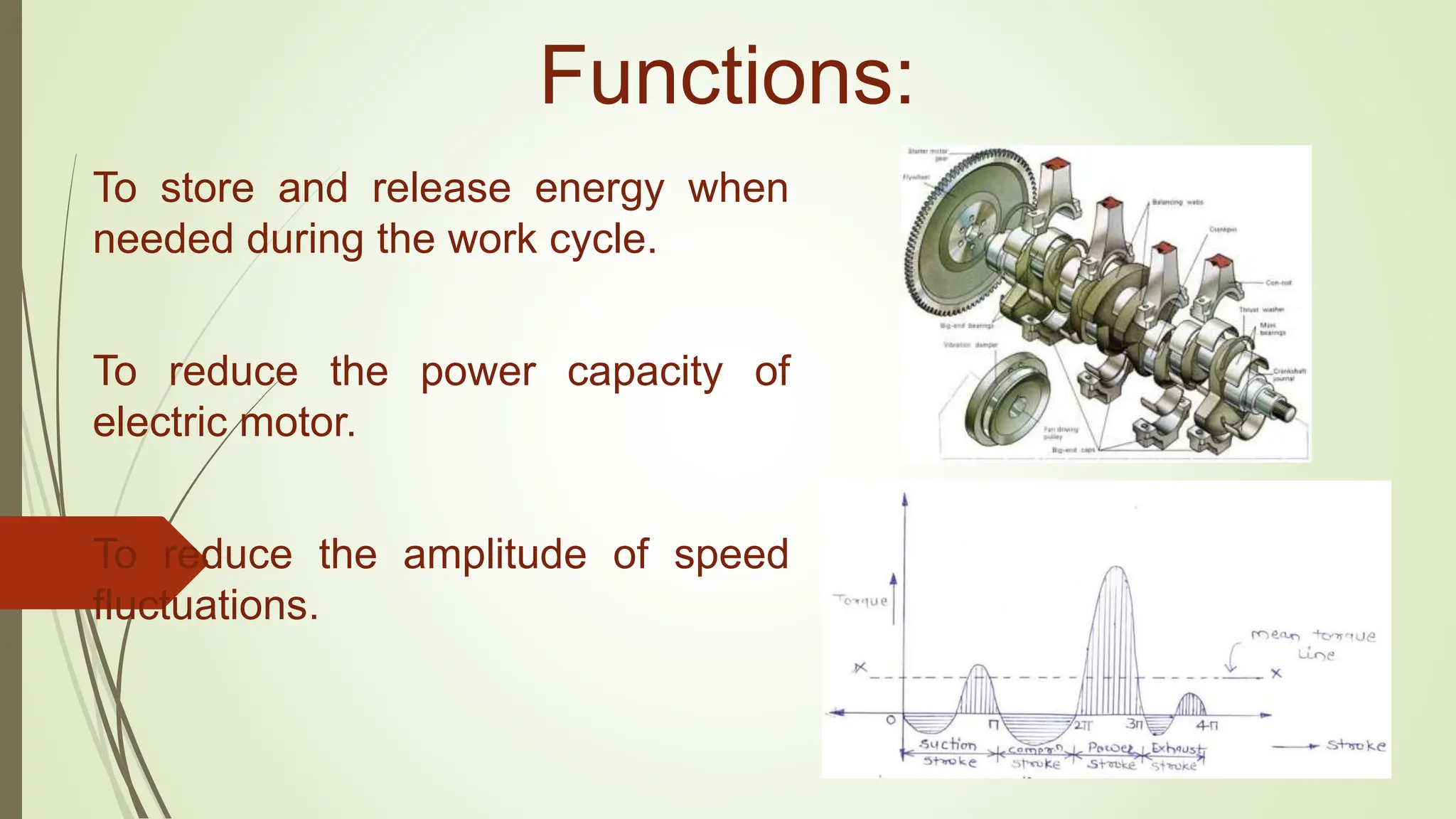

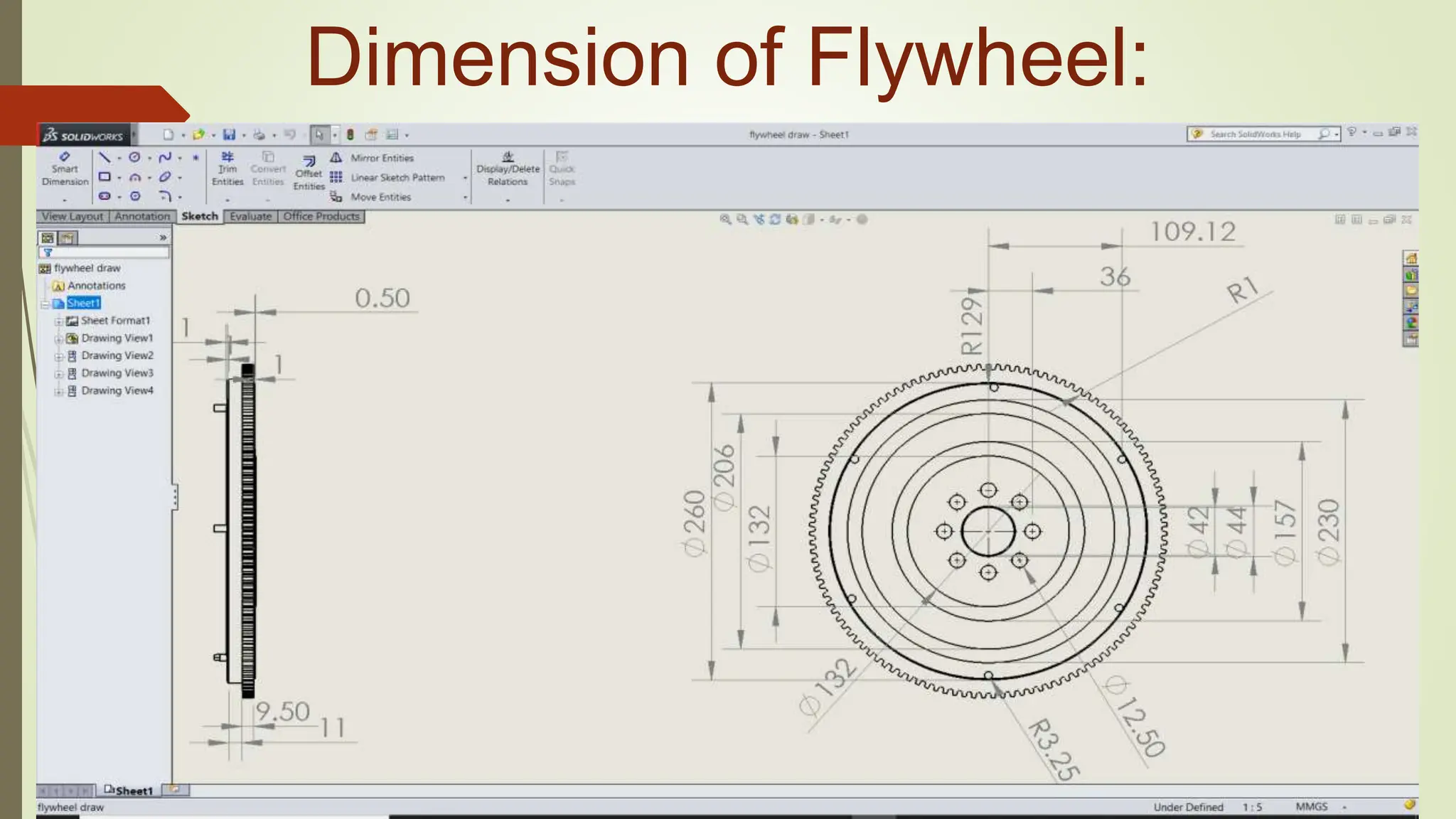

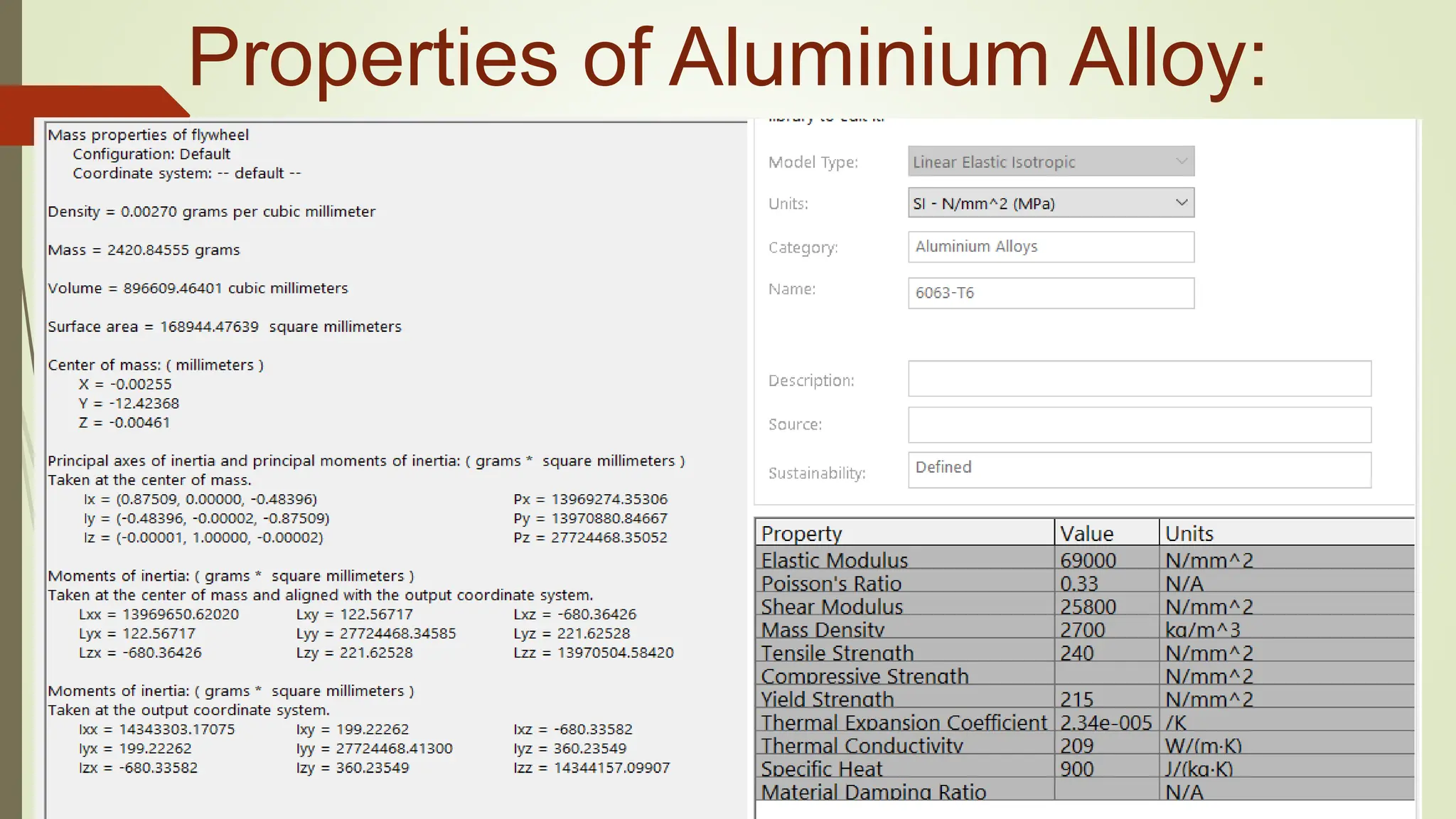

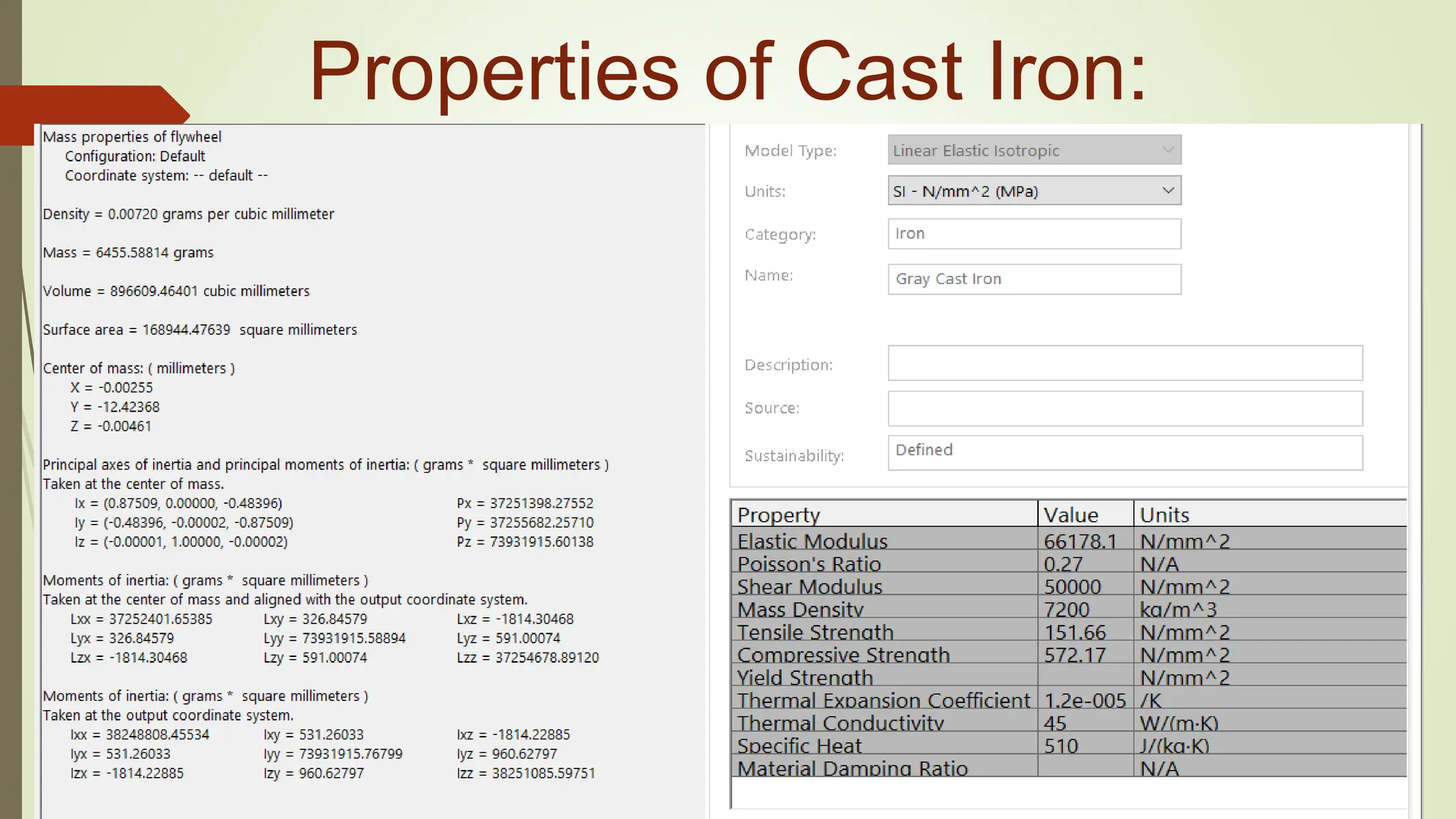

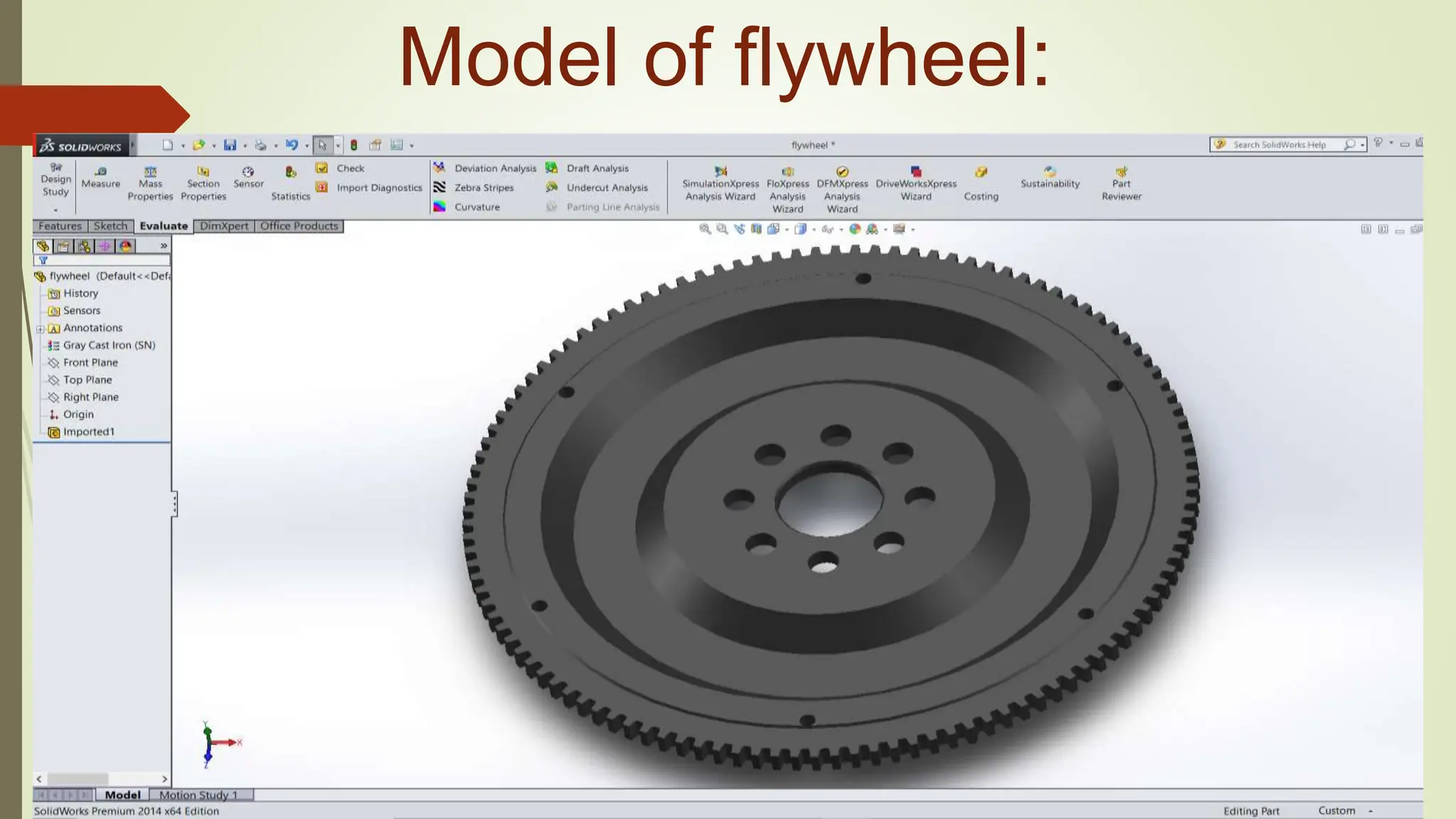

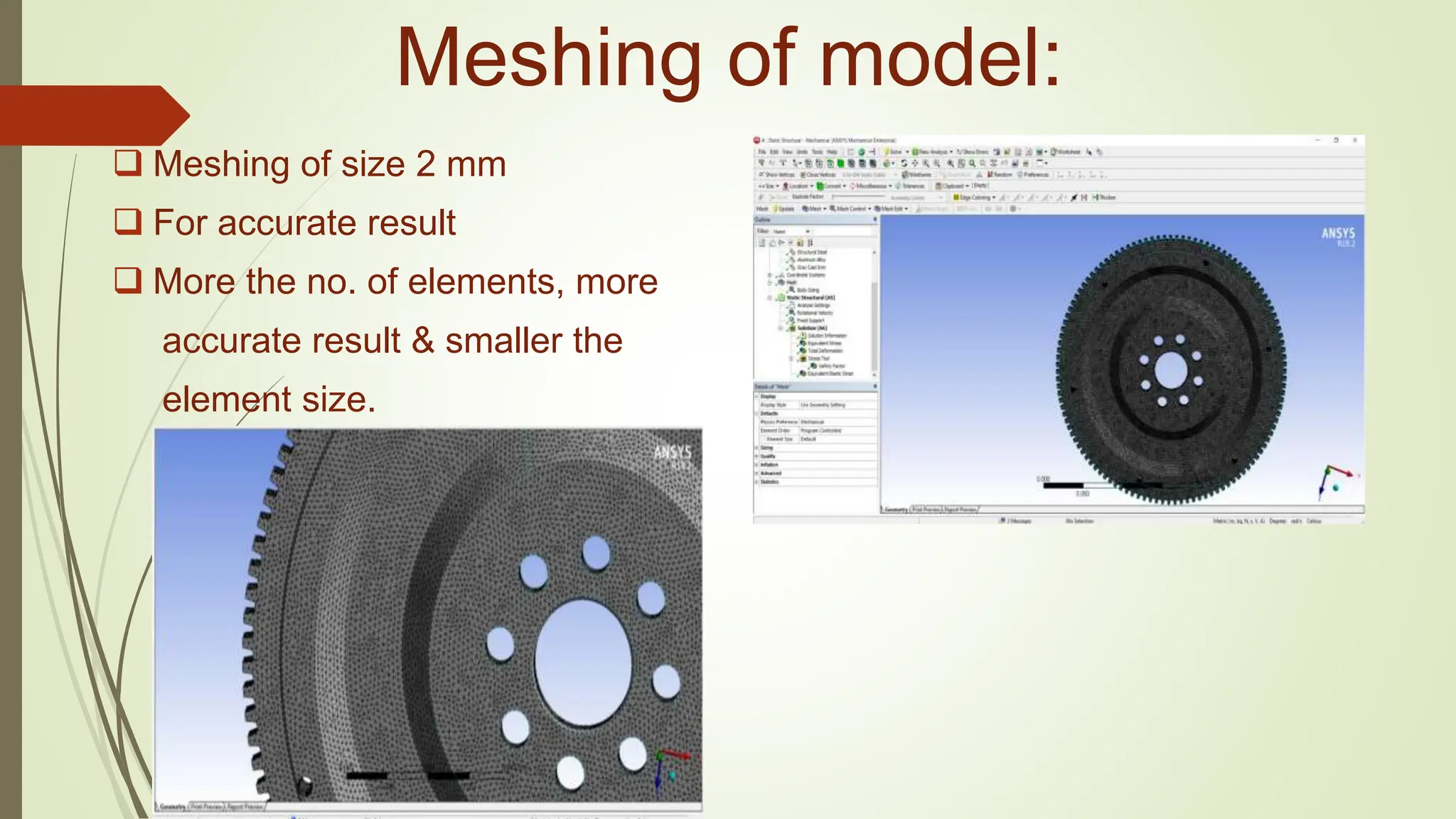

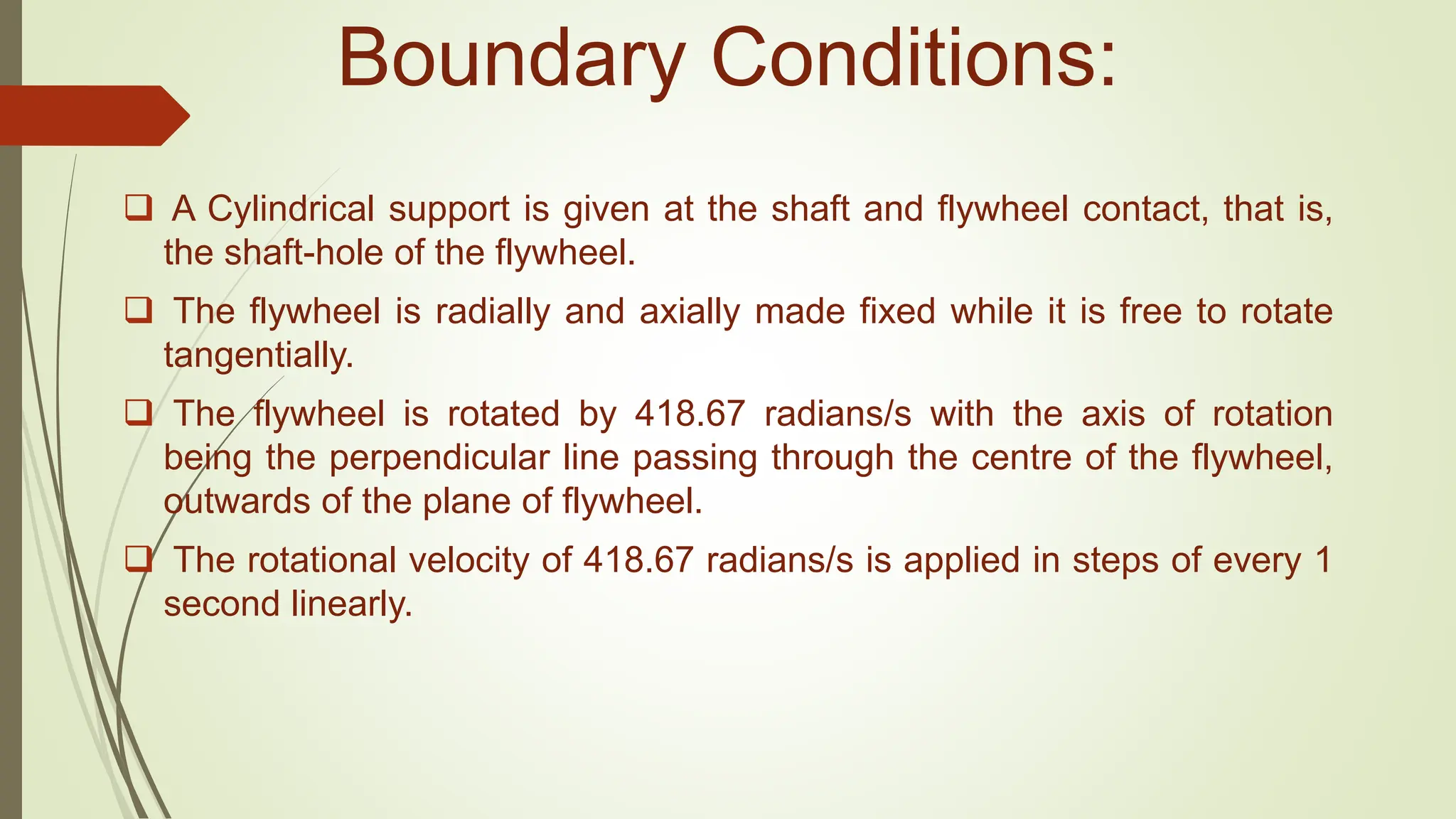

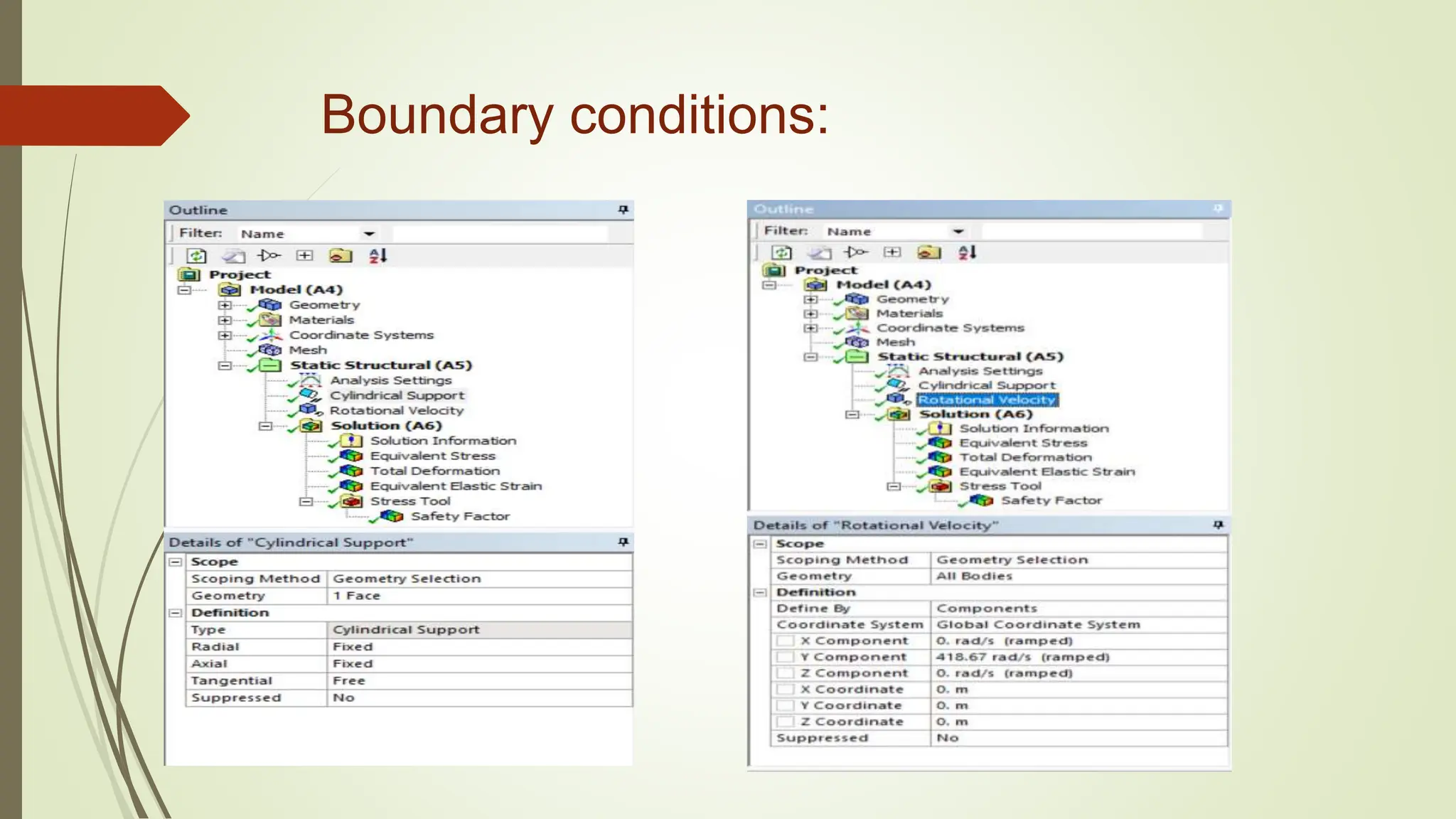

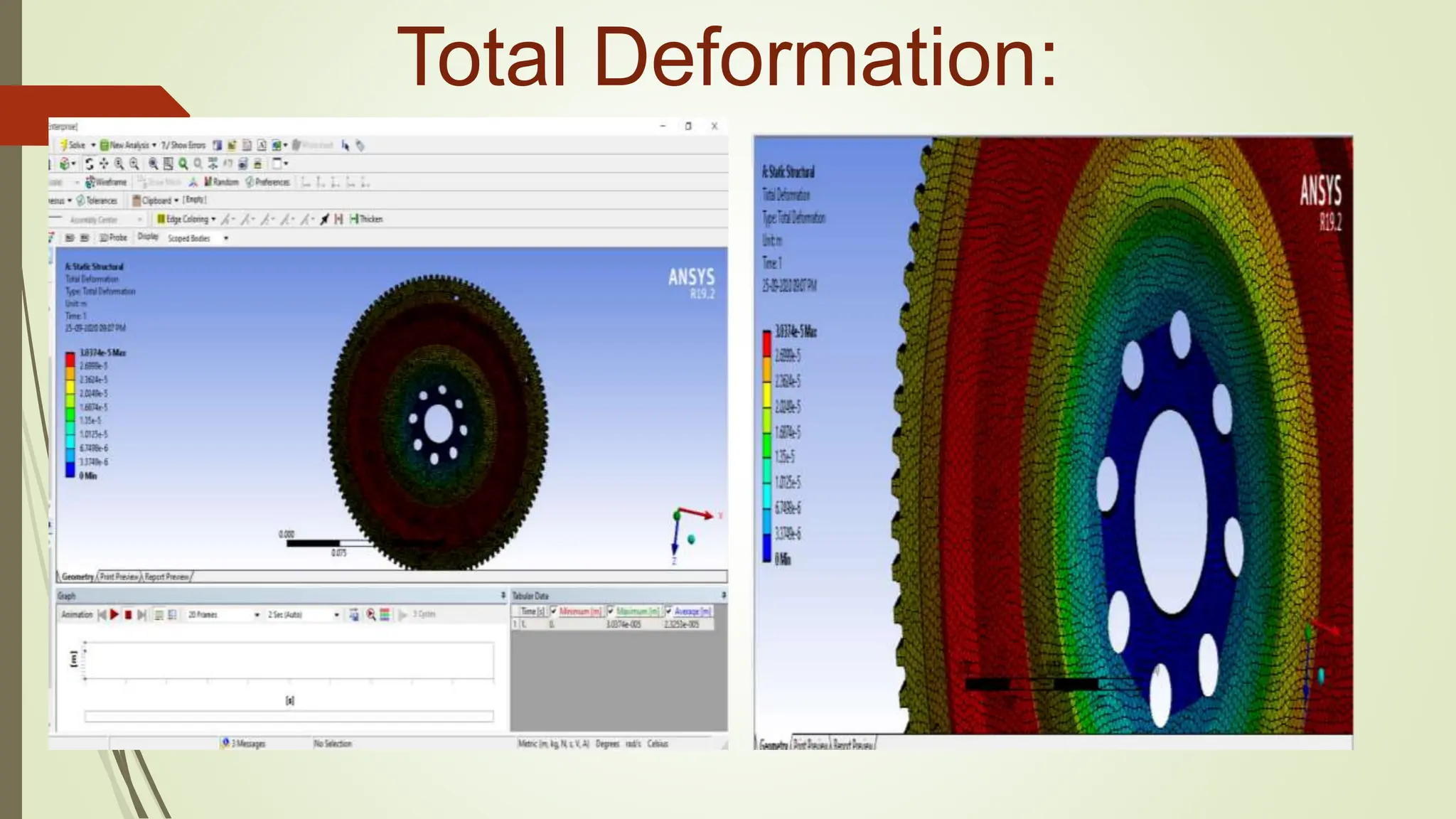

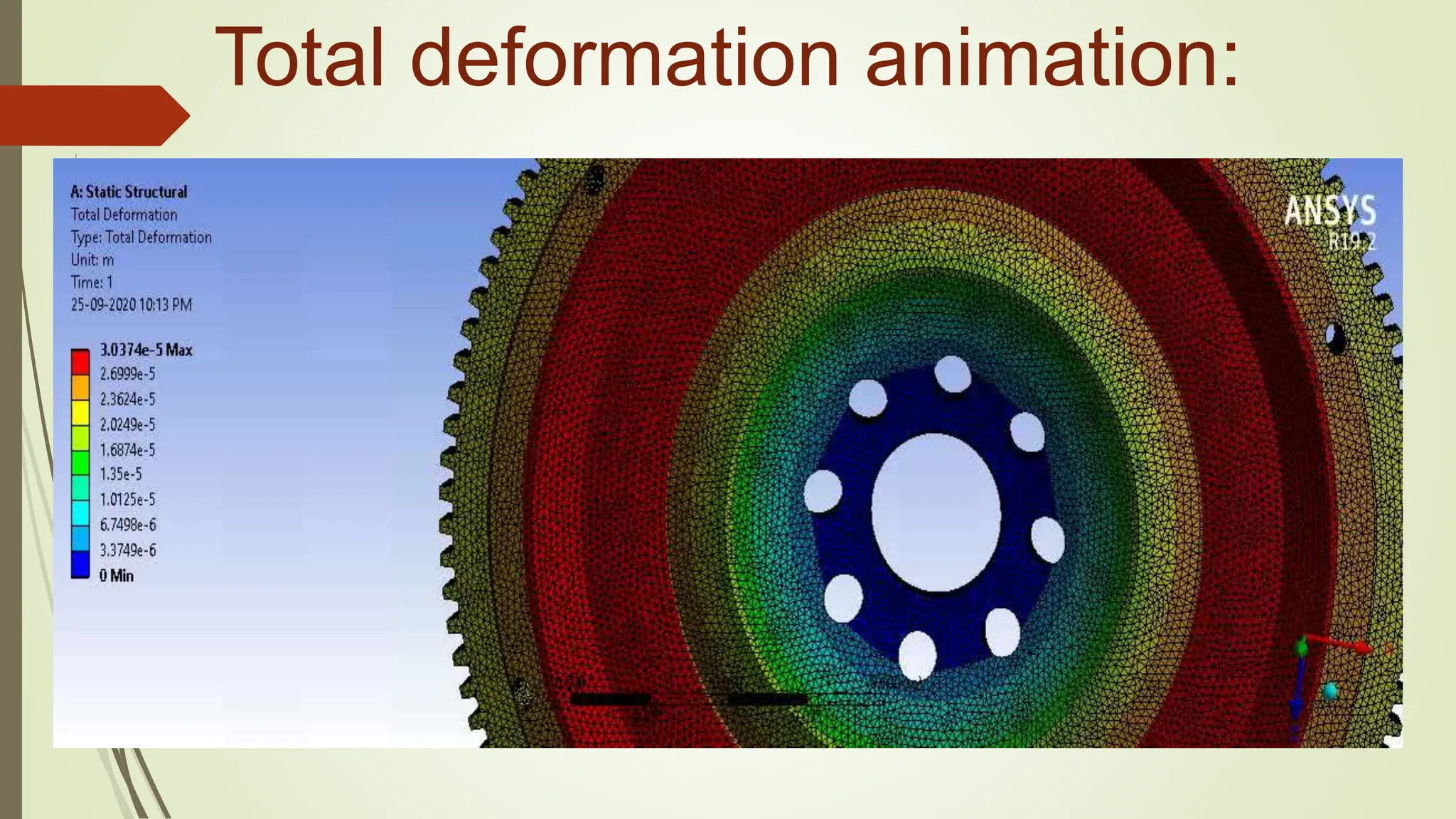

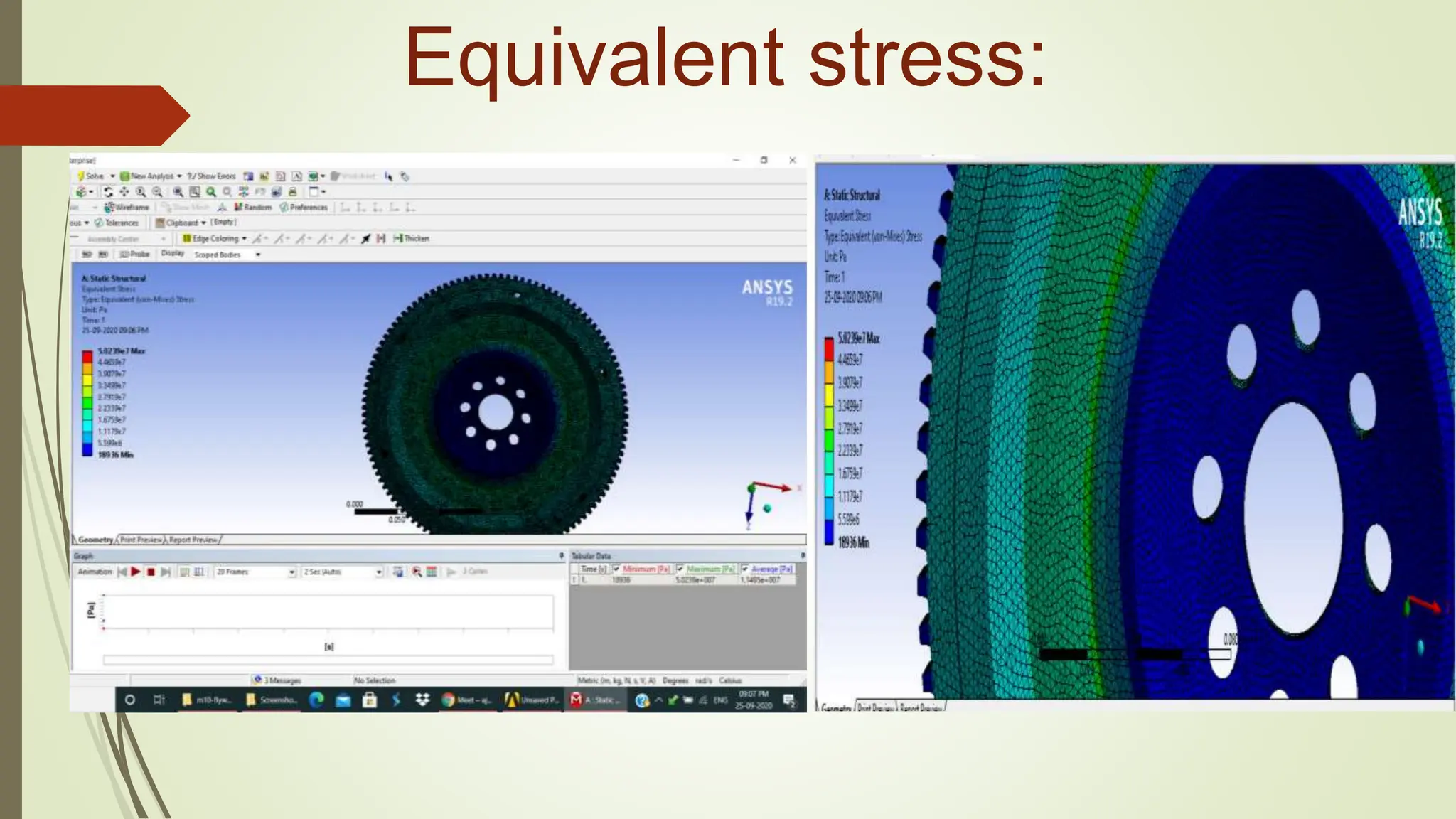

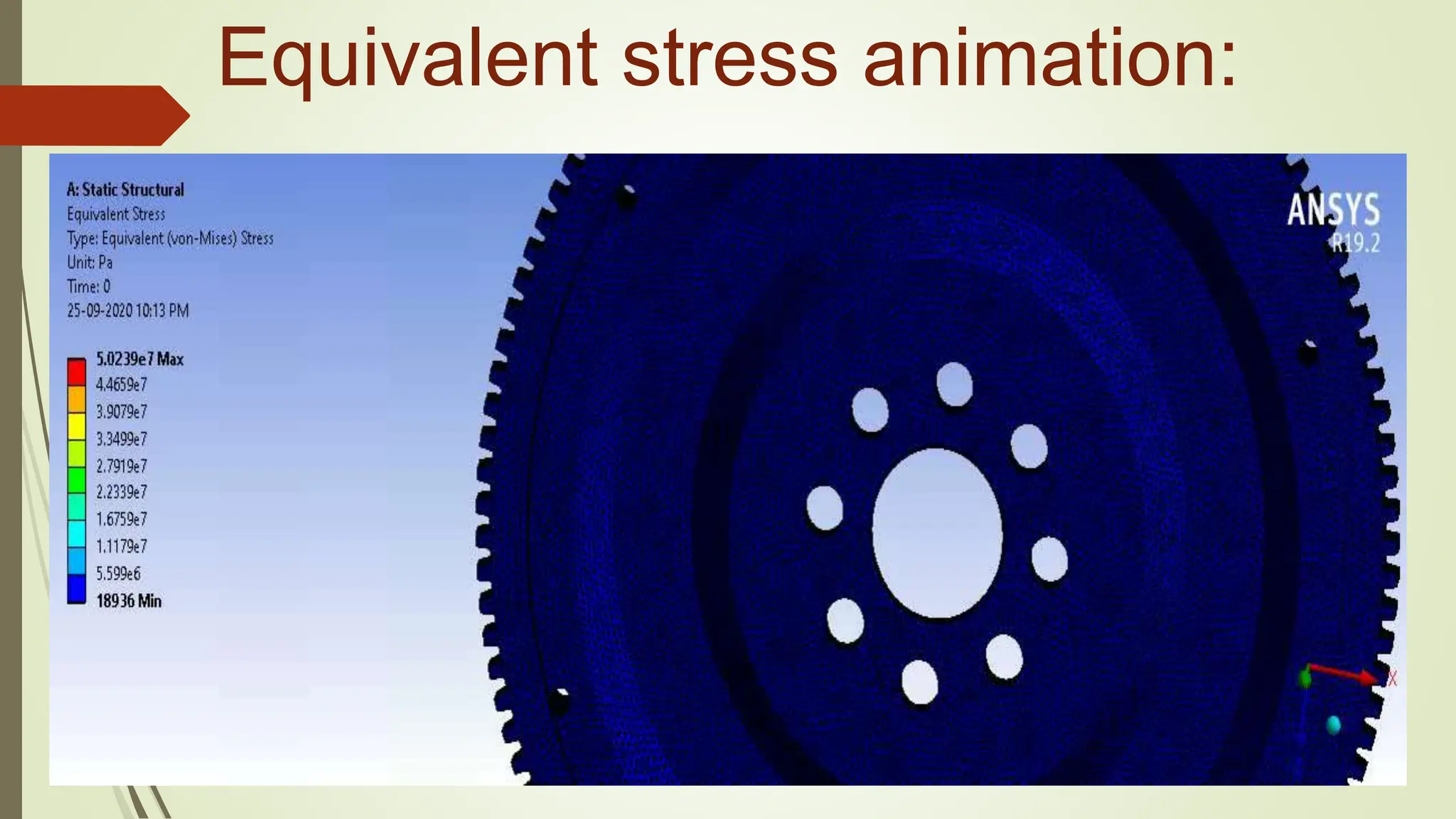

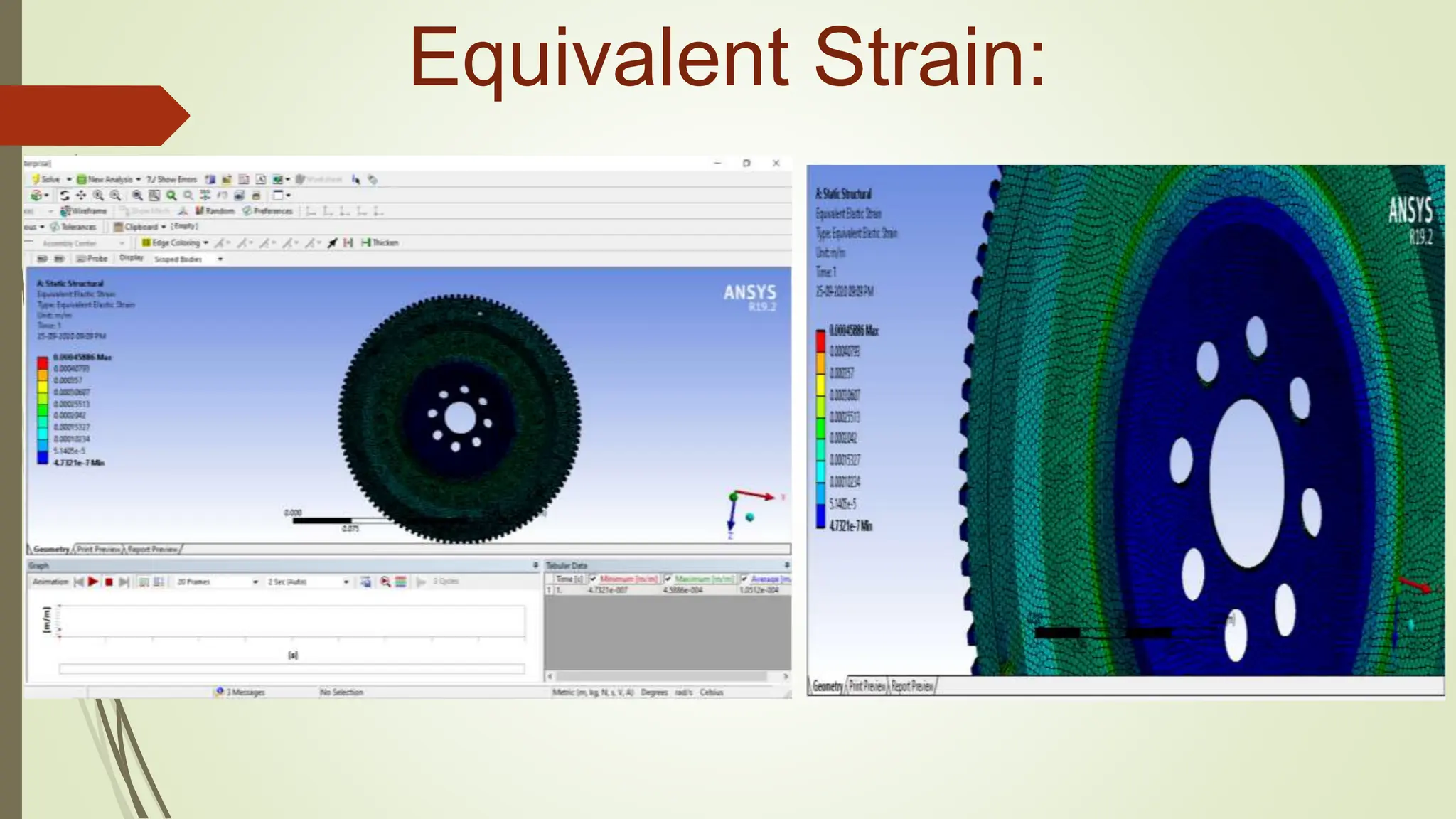

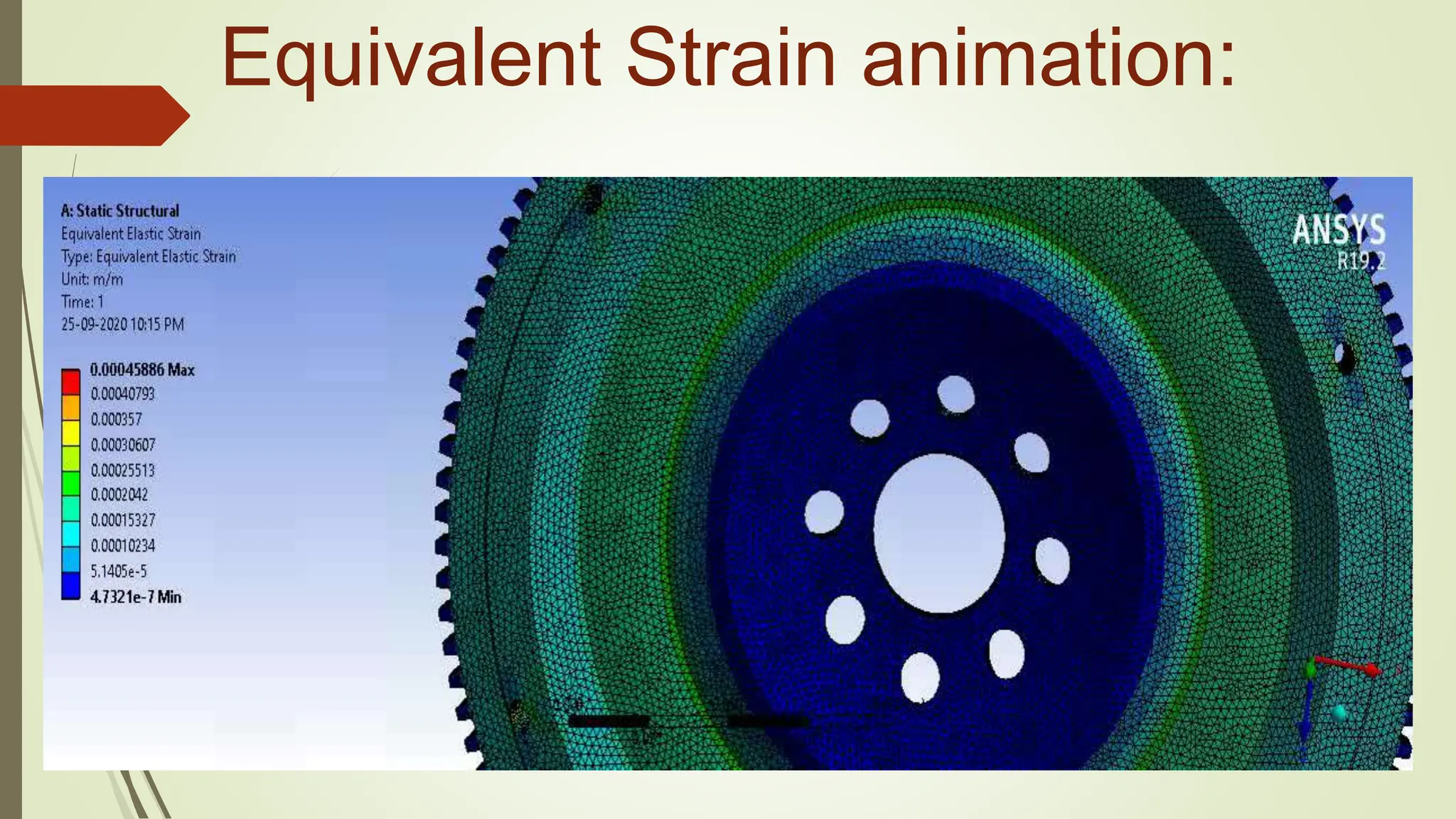

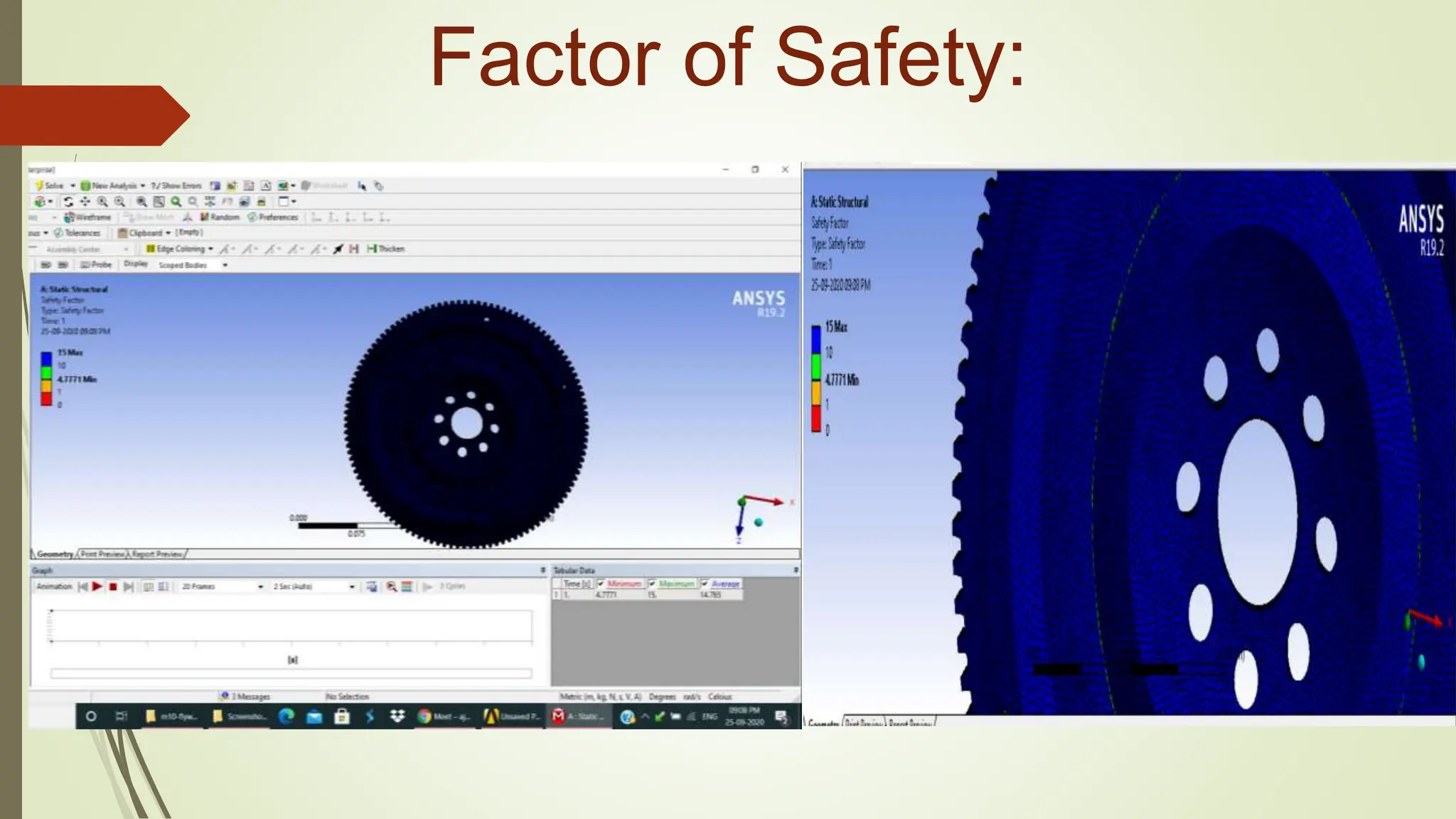

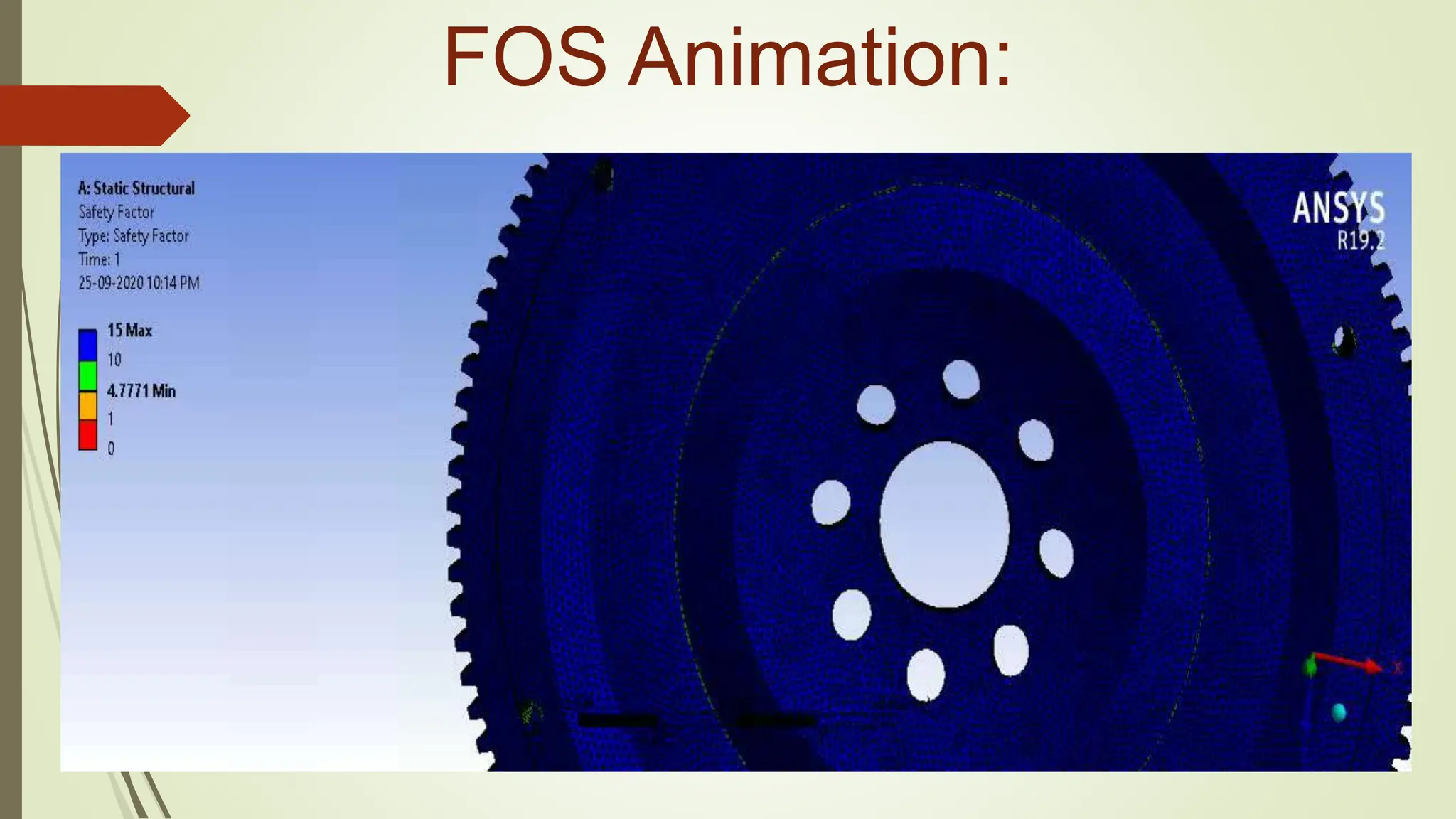

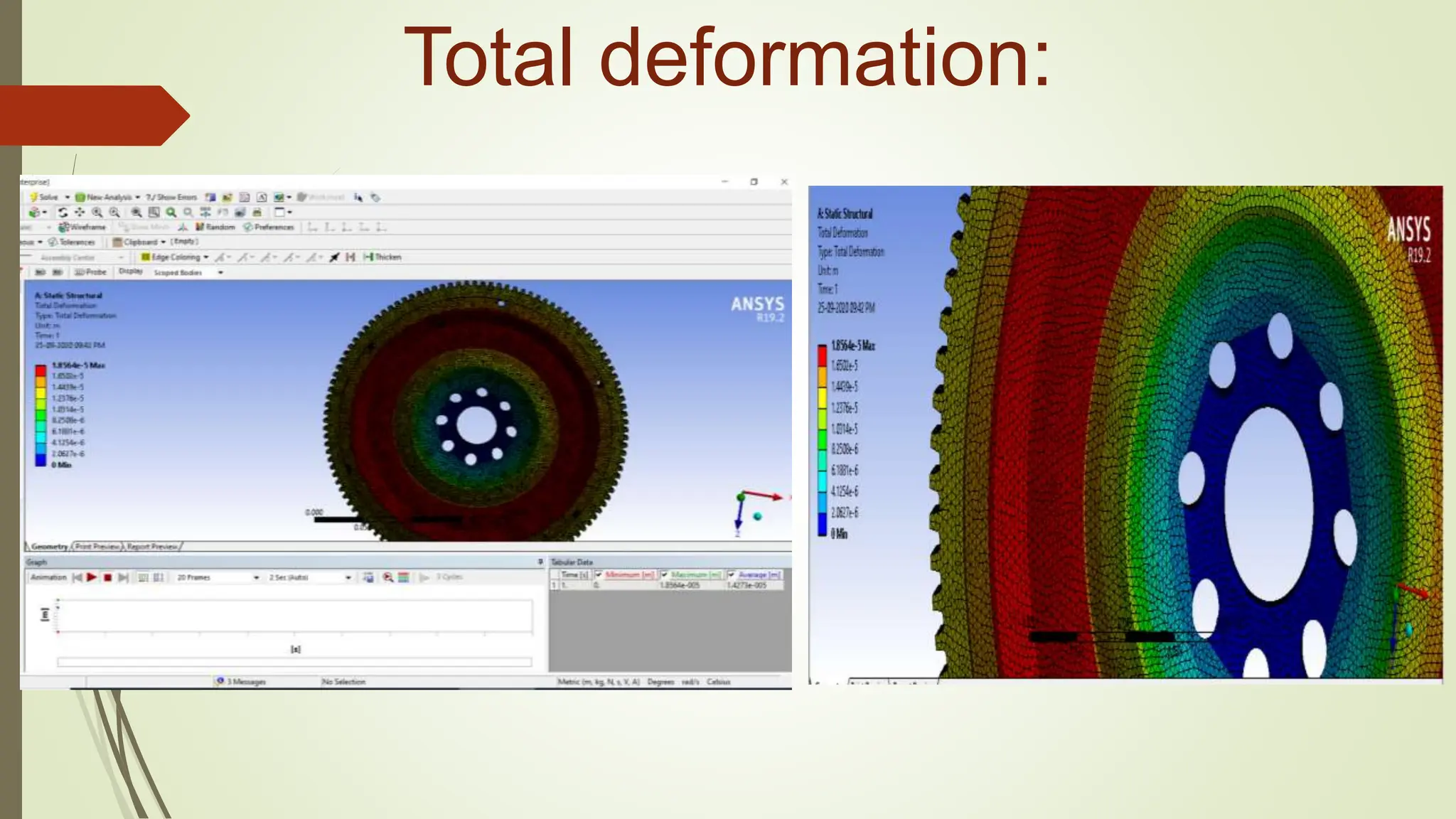

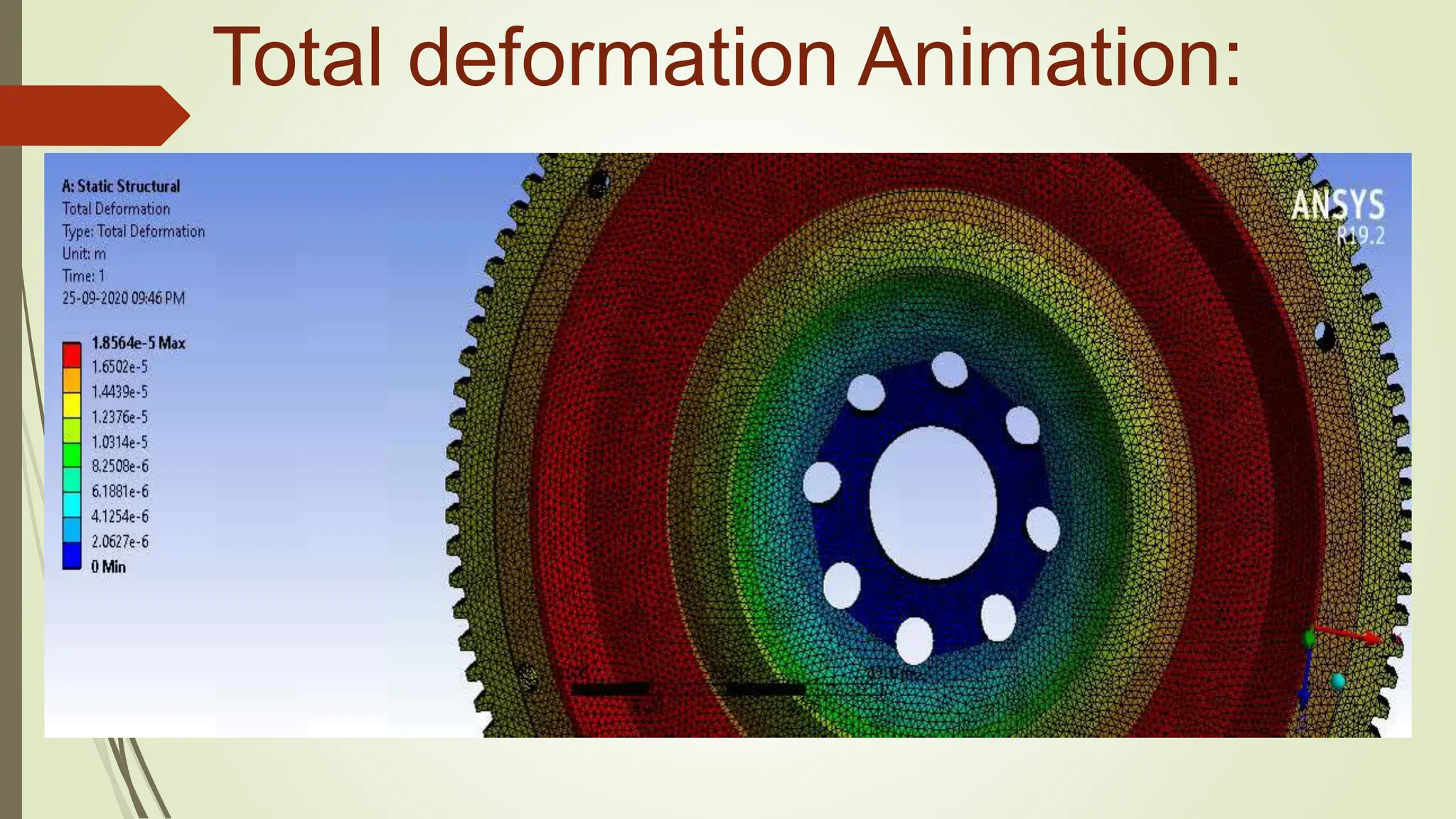

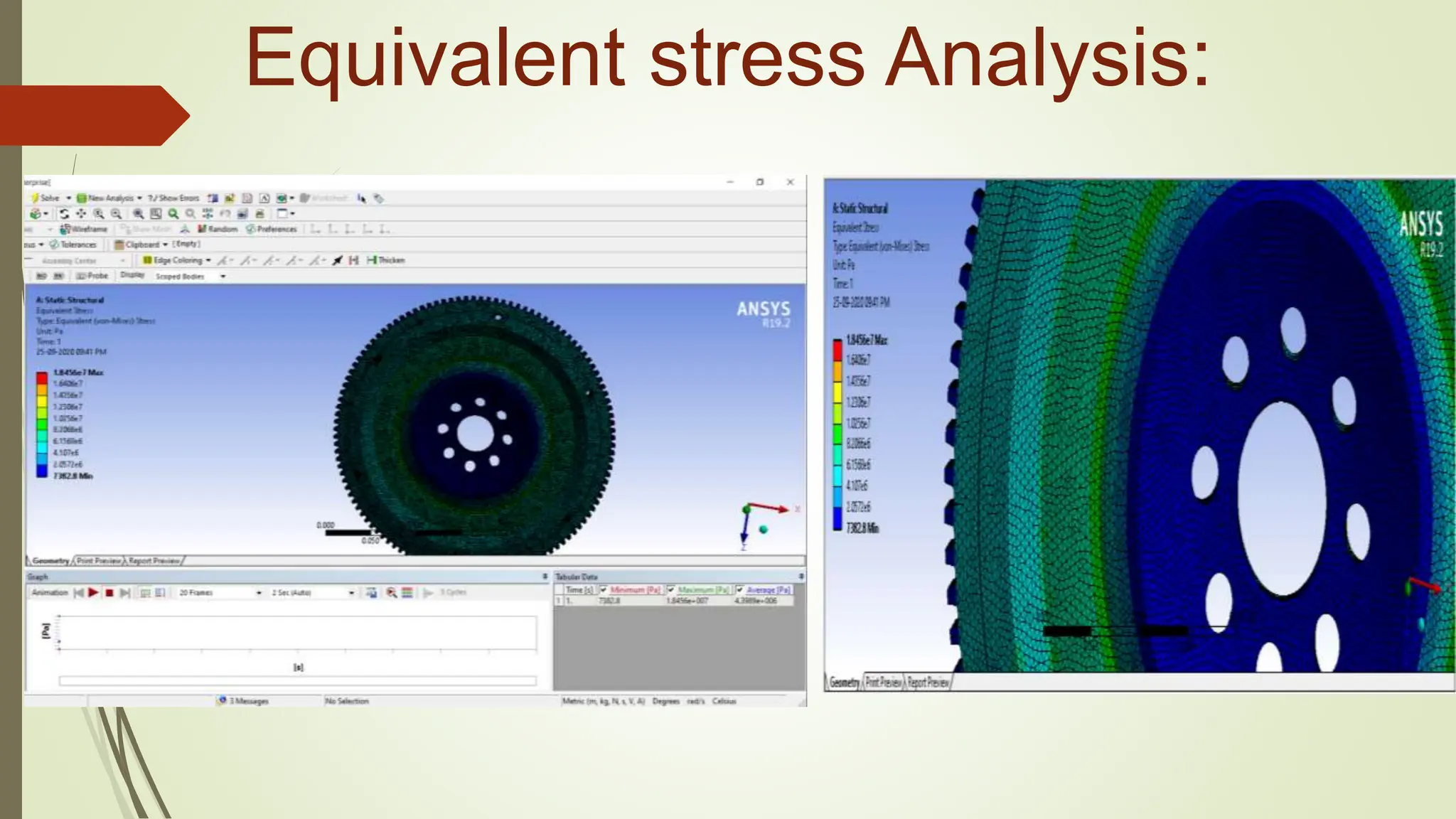

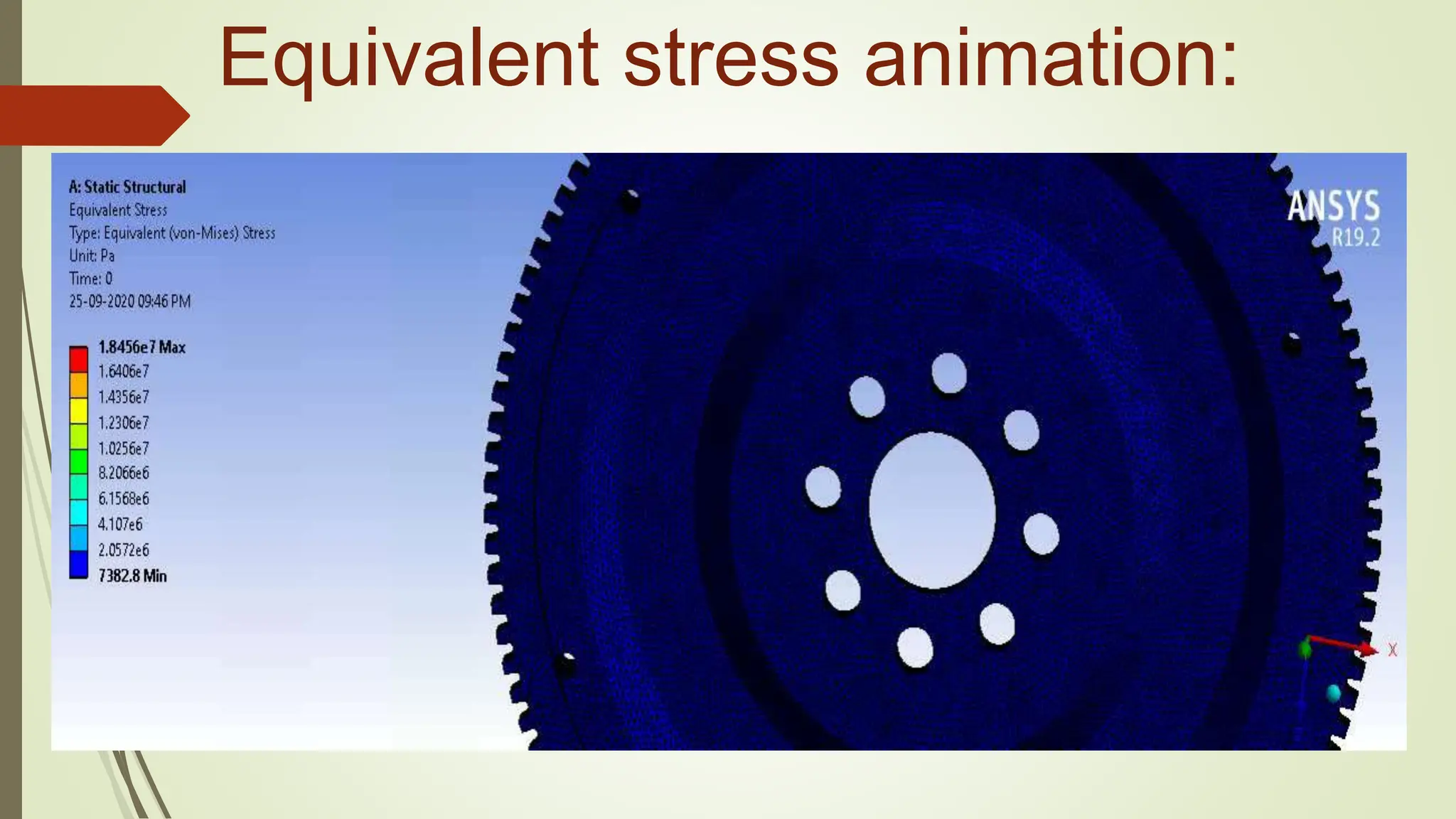

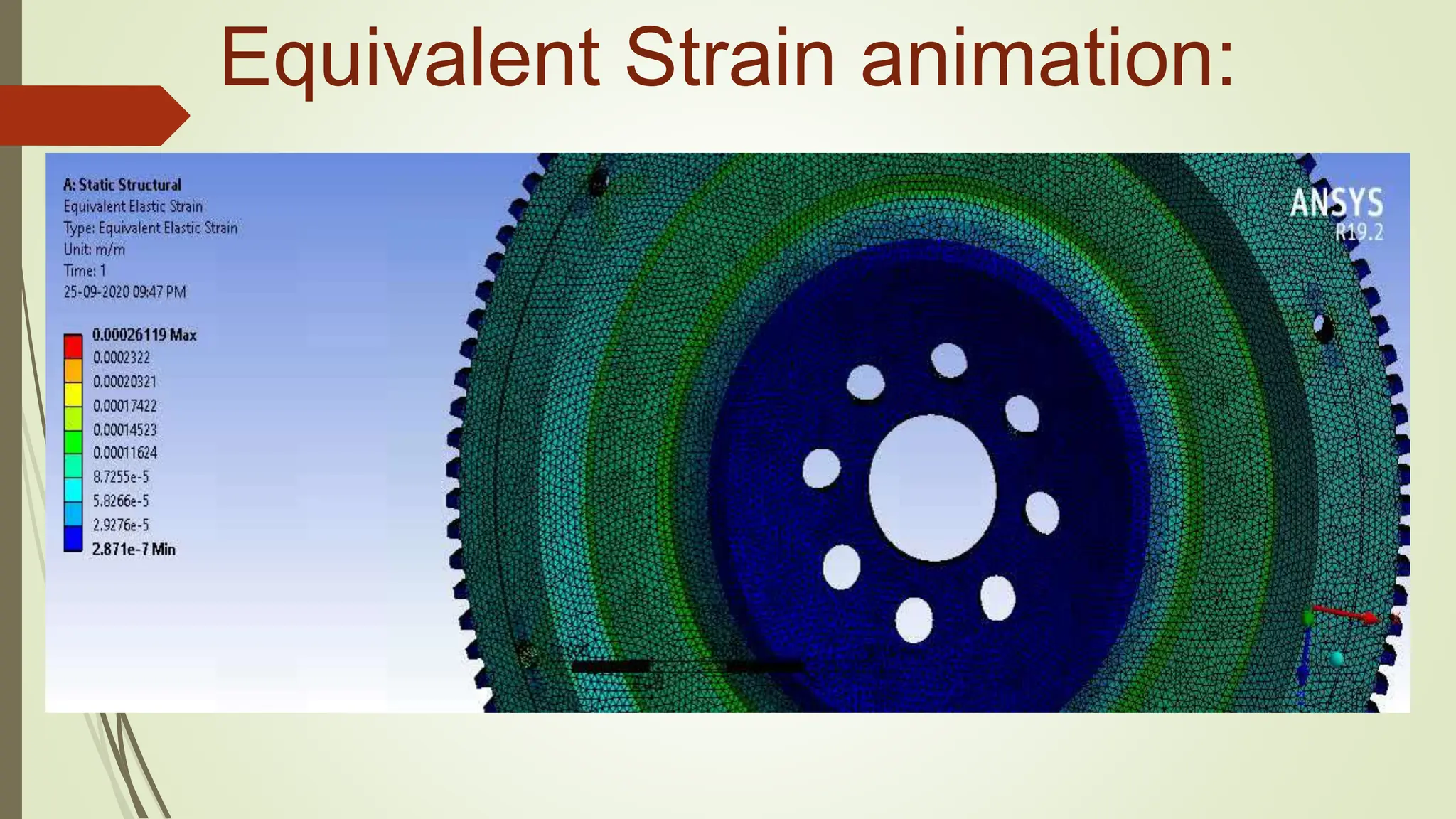

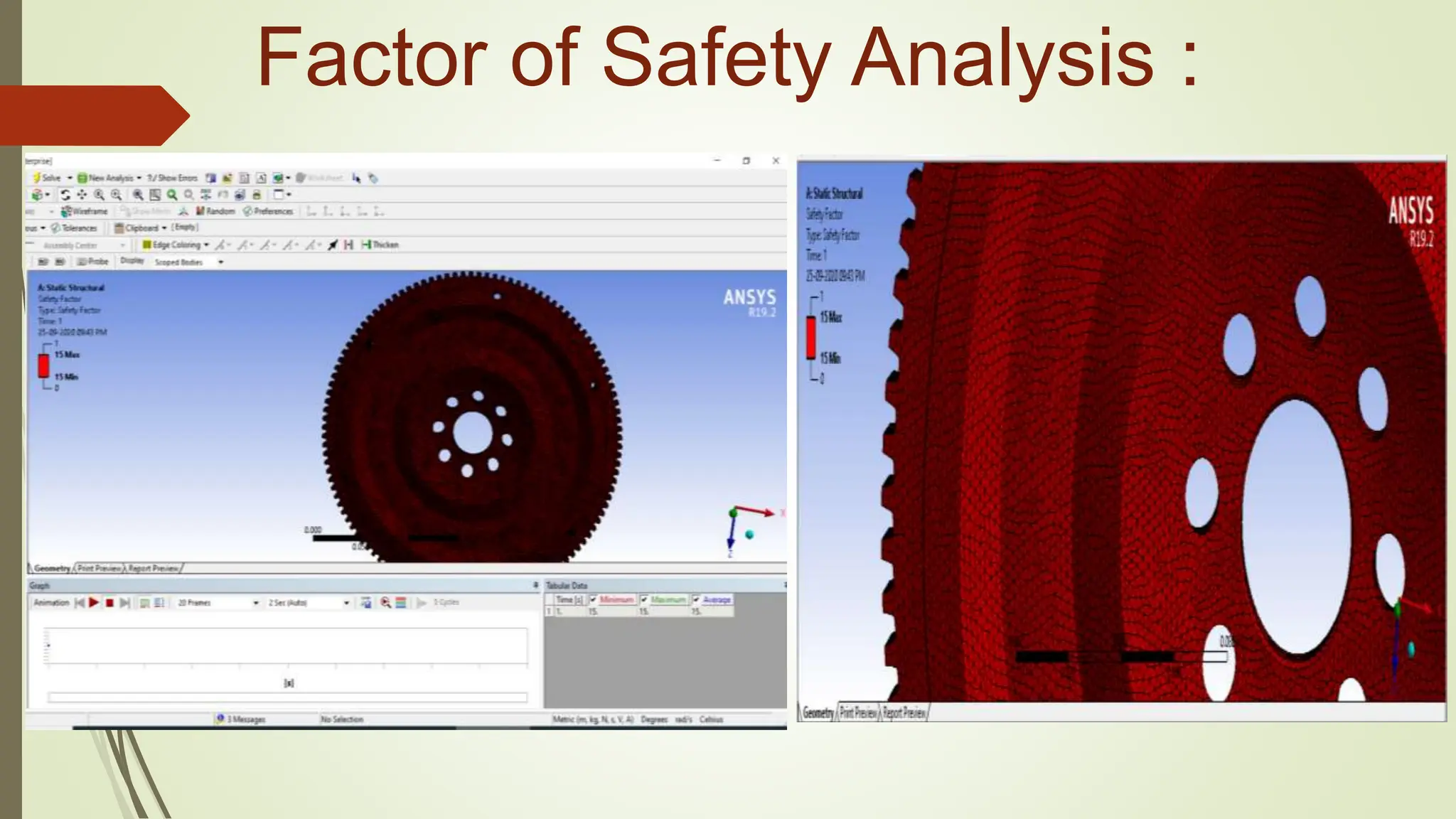

This document summarizes a project analyzing the static and dynamic behavior of a flywheel made from two materials: aluminum alloy and gray cast iron. The objectives were to determine the total deformation, equivalent stress, equivalent strain, and factor of safety for each material. The flywheel was modeled in SolidWorks and analyzed in ANSYS Workbench. The results showed lower stresses in the aluminum alloy flywheel compared to the gray cast iron one, making aluminum alloy better suited for withstanding the rotational forces while keeping weight lower.