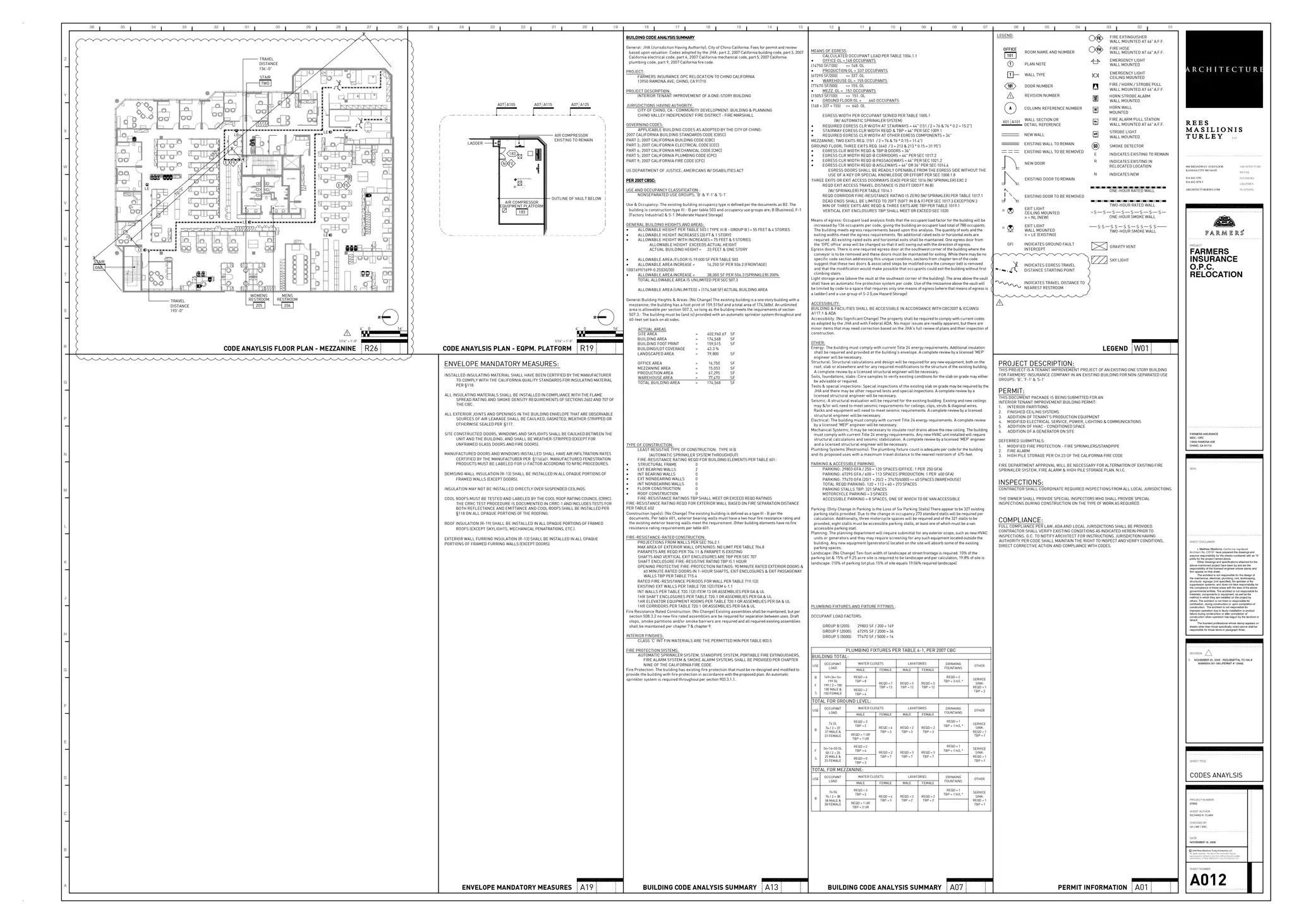

The document provides a code analysis summary for a proposed tenant improvement project at an existing one-story building. The building has a footprint of 159,515sf and total area of 174,568sf. The occupancies include office, production, and warehouse. The analysis finds the building meets egress requirements based on an increased occupant load of 788. Accessibility and parking requirements are identified.

![010203040506070809101112131415161718192021222324252627282930313233343536

Z

Y

X

W

V

U

T

S

R

Q

P

N

M

L

K

J

H

G

F

E

D

C

B

A

ARCHITECTURE

RETAIL

INTERIORS

GRAPHICS

PLANNING

L L C

f

ARCHITECTURERMT.COM

908 BROADWAY 6TH FLOOR

KANSAS CITY MO 64105

816.842.1878

816.842.1292

PROJECT

SEAL

SHEET DISCLAIMER

REVISION

SHEET TITLE

SHEET AUTHOR

CHECKED BY

DATE

SHEET NUMBER

All rights reserved. No part of this document may be

reproduced or utilized in any form without the prior written

authorization of Rees Masilionis Turley Architecture, LLC.

c 2008 Rees Masilionis Turley Architecture, LLC

NOVEMBER 18, 2008

07655

PROJECT NUMBER

FARMERS INSURANCE

MDC / OPC

13950 RAMONA AVE

CHINO, CA 91710

RELOCATION

O.P.C.

INSURANCE

FARMERS

I, Matthew Masilionis, California registered

Architect No. C29101 have prepared the drawings and

assume responsibility for the sheets numbered with an "A"

prefix for the project named above.

Other drawings and specifications attached for the

above-mentioned project have been by and are the

responsibility of the licensed engineer whose stamp and

firm appear on that sheet.

The architect is not responsible for the design of

the mechanical, electrical, plumbing, civil, landscaping,

structural, signage (not specified), fire sprinkler or fire

suppression systems; and does not take responsibility for

the compliance of these areas with the laws of the above

governmental entities. The architect is not responsible for

materials, components or equipment, as well as the

method in which they are installed on the project by

others. The architect is not hired or responsible for

certification, during construction or upon completion of

construction. The architect is not responsible for

improper operation due to faulty installation or product

failure during construction or after completion of

construction when operation has begun by the landlord or

tenant.

The licensed professional whose stamp appears on

sheets other than those specifically noted above shall be

responsible for those items in paragraph three.

SH / MP / RRC

A01TITLE 24 - BUILDING ENVELOPE

TITLE 42

BUILDING ENVELOPE

RICHARD R. CLARK

A031

GENERAL INFORMATION

BUILDING TYPE

CERTIFICATE OF COMPLIANCE ENV-1-C(Part 1 of 2)

PROJECT NAME

PROJECT ADDRESS

PRINCIPAL DESIGNER-ENVELOPE

DOCUMENTATION AUTHOR

TELEPHONE

TELEPHONE

DATE OF PLANS BUILDING CONDITIONED FLOOR AREA CLIMATE ZONE

NONRESIDENTIAL HIGH RISE RESIDENTIAL HOTEL/MOTEL GUEST

DATE

Building Permit #

Checked by/Date

Enforcement Agency Use

2005 Nonresidential Compliance Forms January 2006

RELOCATABLE - Indicate: specific climate - list ____________________________, or all climates

PHASE OF CONSTRUCTION NEW CONSTRUCTION ADDITION ALTERATION UNCONDITIONED

METHOD OF ENVELOPE

COMPLIANCE

COMPONENT OVERALL ENVELOPE

SUPPORTING FORMS

SUBMITTED

ENV-2-C (Component) ENV-3-C (Overall Envelope) ENV-4-C (Skylight Worksheet)

STATEMENT OF COMPLIANCE

This Certificate of Compliance lists the building features and performance specifications need to comply with Title 24, Parts 1 and 6 of the California

Code of Regulations. This certificate applies only to building envelope requirements.

The documentation preparer hereby certifies that the documentation is accurate and complete.

DOCUMETNATION AUTHOR SIGNATURE DATE

The Principal Envelope Designer hereby certifies that the proposed building design represented in this set of construction documents is consistent

with the other compliance forms and worksheets, with the specifications, and with any other calculations submitted with this permit application. The

proposed building has been designed to meet the envelope requirements contained in sectiosn 110, 116 through 118, and 140, 142, 143 or 149 of

Title 24, Part 6. Please check one:

I hereby affirm that I am eligible under the provisions of Division 3 of the Business and Professions Code to sign this document as the person

responsible for its preparation; and that I am licensed in the State of California as a civil engineer or mechanical engineer, or I am a licensed

architect.

I affirm that I am eligible under the provisions of Division 3 of the Business and Professions Code by section 5537.2 or 6737.3 to sign this

document as the person responsible for its preparation; and that I am a licensed contractor performing this work.

I affirm that I am eligible under Division 3 of the Business and Professions Code to sign this document because it pertains to a structure or type

of work described as exempt pursuant to Business and Professions Code Sections 5537, 5538 and 6737.1.

(These sections of the Business and Professions Code are printed in full in the Nonresidential Manual.)

PRINCIPAL ENVELOPE DESIGNER NAME SIGNATURE DATE LIC #

ENVELOPE MANDATORY MEASURES

Indicate location on plans of Note Block for Mandatory Measures A13/A001 -or- A01/A031

INSTRUCTIONS TO APPLICANT ENVELOPE COMPLIANCE & WORKSHEETS (check box if worksheet is included)

For detailed instructions on the use of this and all Energy Efficiency Standards compliance forms, please refer to the Nonresidential Manual published

by the California Energy Commission.

ENV-1-C

ENV-2-C

ENV-3-C

ENV-4-C

Certificate of Compliance. Required on plans for all submittals. Part 2 may be incorporated in schedules on

plans.

Use with the Envelope Component compliance method.

Use with the Overall Envelope compliance method.

Optional. Use for the minimum skylight requirements for large enclosed spaces.

(file

affidavit)

FARMERS INSURANCE - O.P.C. RELOCATION 11/18/2008

13950 RAMONA AVE; CHINO, CA 91710

MATT MASILIONIS 816/842-1292

816/842-1292

11/18/2008 1050,046.SF

X

X

X

X

MATT MASILIONIS

MATT MASILIONIS

11/18/2008

X

MATT MASILIONIS 11/18/2008 C29101

X

X

OPAQUE SURFACES

CERTIFICATE OF COMPLIANCE ENV-1-C(Part 2 of 2)

PROJECT NAME DATE

2005 Nonresidential Compliance Forms January 2006

Surface

Type SQFT U-factor

Insulation

Cavity Continuous

Actual

Azimuth Tilt

Condition

Status*

Joint App

IV Reference

Location/Comments

(e.g.,Suspended

Ceiling, Demising, etc.)

NOTES TO FIELD

For Building

Use Only

FENESTRATION SURFACES

* N, E, A, (New, Existing, Altered)

More than or equal to 10,000 ft of site-built fenestration area must include a label certificate issued by NFRC or provide a CEC Default

Label Certificate using the default U-factors from Standard Tables 116-A and B. Certificate shall be filed in the contractor's project office during

construction and in the building manager's office after construction.

A B C D E F G H I J K

Fenestration Name

Fenestration

Type Area Azimuth

U-

factor

U-factor

Type

D A N

Fenestration

SHGC

SHGC

Type

D C N

2 Condition

Status 3 Location / Comments

NOTES TO FIELD -

For Bldg. Dept.

Use Only

U-factor Type: D, A or N (D for Default Table from Section 116, A for ACM Manual Appendix Default Table, or N for NFRC Labeled)

SHGC Type: D, C or N (D for Default table from Section 116, C for Center of Glass, or N for NFRC).

Condition Status: N, E, or A (New, Existing, or Altered).

1

1

2

3

EXTERIOR SHADING

Fenestration

Name

Exterior Shade

Type SHGC

Window

Height Width Length Height LExt. RExt.

Overhang

MINIMUM SKYLIGHT AREA FOR LARGE ENCLOSED SPACES

The proposed building contains an enclosed space with floor area greater than 25,000 ft , a ceiling height greater than 15 feet, and an

LPD for general lighting of at least 0.5 W/ft. If this box is checked, ENV-4-C must be filled out.

NOTES TO FIELD - For Building Department Use Only

2

2

Construction

Type

KJIHGFEDCBA

Window

Window

Window

Window

Skylight

Skylight

Skylight

Skylight

FARMERS INSURANCE - O.P.C. RELOCATION 11/18/2008

E0-

WOOD

50046ROOF

WALL-F

WALL-3

FRAME

CONCRETE

METAL

METAL

FRAME

WALL-F

CONCRETE

WALL-F

CONCRETE

3494

10903

3789

7482

A

A

A

N

90

90

90

90

0%

90%

180%

270%

EXTERIOR

EXTERIOR

EXTERIOR

DEMISING

WALL-E

METAL

FRAME 830 E900% ADIABATIC

E180-50046FLOOR

SLAB ON

GRADE

DOORS

METAL

DOORS 142 E90 DOORS0.700

Area

IV.5 A2--

--

-R-19

R-0-

--

-R-19

0.153

-

0.167

0.049

IV.11 A30

IV.26 A1

IV.13 E5

IV.2 A22

WALL-3

METAL

FRAME 345 N90180% DEMISING-R-19

ROOF/CEILING

EAST FACE

SOUTH FACE

WEST FACE

NORTH

NORTH DEMISING

FLOOR

NORTH

WALL-E

METAL

FRAME 3381 E90270% ADIABATIC--

0.153 IV.11 A30

NORTH DEMISING

DOORS

METAL

DOORS 21 E90 DOORS0.700 IV.5 A2--

DOORS

METAL

DOORS 142 E90 DOORS0.700 IV.5 A2--

DOORS

METAL

DOORS 21 E90 DOORS0.700 IV.5 A2-- 0%

90%

180%

270%

- -

- -

R-13 IV.19 N17FURRING

METAL

FURRING

METAL

FURRING

-- IV.13 E5

R-13 IV.19 N17

-- IV.13 E5

R-13 IV.19 N17

0.167

0.167

ENVELOPE COMPONENT METHOD ENV-2-C(Part 1 of 2)

PROJECT NAME DATE

WINDOW AREA CALCULATION

FT×6 FT =

SF×0.40 =

SF MINIMUM STANDARD AREA

SF

SF DISPLAY AREA

SF PROPOSED WINDOW AREA

C. ENTER LARGER OF A OR B

A. DISPLAY PERIMETER

B. GROSS EXTERIOR WALL AREA

January 20062005 Nonresidential Compliance Form

D. ENTER PROPOSED WINDOW AREA

If the PROPOSED WINDOW AREA is greater than the MAXIMUM STANDARD AREA then the envelope component method may not be used.

E. WINDOW WALL RATIO = Proposed Window Area Divided by Gross Exterior Wall Area =

F. WEST DISPLAY PERIMETER

G. WEST EXTERIOR WALL AREA

H. ENTER THE LARGER OF F AND G

I. ENTER PROPOSED WEST WINDOW AREA

If the PROPOSED WINDOW AREA is greater than the MAXIMUM STANDARD AREA then the envelope component method may not be used.

J. WEST WINDOW WALL RATIO = Proposed West Window Area Divided by West Exterior Wall Area =

SKYLIGHT AREA CALCULATION

FT×6 FT =

SF×0.40 =

SF

SF

SF

SF

A. ATRIUM or SKYLIGHT HEIGHT

GROSS ROOF

AREA

FT

SF X 0.05 =

SF X 0.10 =

STANDARD

ALLOWED

SKYLIGHT AREA

SF

SFB. IF Atrium/Skylight Height in A <= 55 FT

C. IF Height in A > 55 FT

D. PROPOSED SKYLIGHT AREA

SF

If the PROPOSED SKYLIGHT AREA is greater than the STANDARD ALLOWED SKYLIGHT AREA then the envelope component

method may not be used.

SKYLIGHTS

SKYLIGHT NAME

(e.g., Sky-1, Sky-2)

SKYLIGHT GLAZING # OF

PANES

U-FACTOR SOLAR HEAT GAIN COEFFICIENT

With

Curb

With No

Curb

Plastic

PROPOSED ALLOWED PROPOSED ALLOWED

40% of GROSS EXTERIOR

WALL AREA

WEST DISPLAY AREA

40% of WEST EXTERIOR

WALL AREA

MAXIMUM STANDARD

WEST AREA

PROPOSED WEST

WINDOW AREA

RELOCATABLE PUBLIC SCHOOL BUILDINGS - See §143(a)8 in the Energy Standards

For Any (All) Climate Zone, use Table 143-C-

Prescriptive Envelope Criteria.

For Specific Climate Zone, use Table 143-A-

Prescriptive Envelope Criteria.

Specific Climate Zone Metal Identification Label - Place two labels on each relocatable

building and indicate on the building plans.

Any (All) Climate Zone Metal Identification Label - Place two labels on each

relocatable building and indicate on the building plans.

FARMERS INSURANCE - O.P.C. RELOCATION 11/18/2008

N/A 0

0

N/A 0

0

26,013. 10,405.2

10,405.2

0

4,134. 1,653.6

1,653.6

0

ENVELOPE COMPONENT METHOD ENV-2-C(Part 2 of 2)

PROJECT NAME DATE

OPAQUE SURFACES

January 2006Nonresidential Compliance Form

ASSEMBLY NAME

(e.g. roof-1, Wall-1,

Floor-1)

TYPE

(e.g. Roof, Wall,

Floor)

HEAT

CAPACITY

INSULATION R-VALUE*

PROPOSED

MINIMUM

ALLOWED PROPOSED

Joint

Appendix IV REF

MAXIMUM

ALLOWED

*For each assembly type, meet the minimum insulation R-value or the maximum assembly U-factor.

WINDOWS

WINDOW NAME

(e.g., Window-1, Window-2)

ORIENTATION Fenestration

U-FACTOR # OF Fen.

N E S W PROP. ALLOW. PANES SHGC*

PROPOSED RSHG

H V H/V OHF

PROP. ALLOWED

RSHG RSHG

* From Fenestration Surfaces ENV-1-C, Part 2, Column G, or when Column H has a "C" identifier, calculate using the center of glass value SHGCc in

SHGCFEN = .08 + (.86 x SHGCc)and enter value.

ASSEMBLY U-FACTOR*

COOL ROOFS - LOW-SLOPED- See Section 3.4 in the NRM and §118(i)3 and §143(a)1 in the Energy Standards for further description about exterior roofs

and mandatory requirements for Cool Roofs.

CHECK APPLICABLE BOXES

Option 1 - Tested - Initial Thermal Emittance >= 0.75 and Initial Solar Reflectance >= 0.70

Proposed emittance and reflectance must be >= the

standard when tested with CRRC-1 Proposed Standard

1. Enter proposed initial thermal emittance, einitial

2. Enter the proposed initial solar relectance, ρinitial

If proposed >= to the standard then it complies.

If proposed >= to the Standard then it complies.

3. When applying Liquid Field Applied Coatings, the coating must be applied with a minimum dry mil thickness of 20 mils across the entire roof surface and

meet minimum performance requirments listed in §118(i)3 and Table 118-C. Select the applicable coating:

Option 2 - CRRC - 1 Tested - Initial Thermal Emittance < 0.75

Aluminum-Pigmented Asphalt

Roof Coating

Cement-Based

Roof Coating

Other: _______________________________________________________

Proposed initial thermal emittance < 0.75 when tested with

CRRC-1 Proposed Standard

1. Enter proposed initial thermal emittance, einitial

2. Enter the initial solar reflectance, ρinitial

3. To apply Liquid Field Applied Coating, the coating must be applied with a minimum dry mil thickness of 20 mils across the entire roof surface and

meet minimum performance requirements listed in §118(i)3 and Table 118-C. Select theapplicable coating:

Aluminum-Pigmented Asphalt

Roof Coating

Cement-Based

Roof Coating

Other: _______________________________________________________

CRRC - 1 Label Attached to Submittal

(Note if no CRRC -1 label is available, this compliance method can not be used.)

> .75

> .70

< 0.75

0.70 + [0.34 x (0.75 - einitial)]

Go to line 2. Insert einitial value in calculation.

ρ

Standard

FARMERS INSURANCE - O.P.C. RELOCATION 11/18/2008

ROOF R-19 R-19 0.051

WALL-F R-13 R-13

WALL-3 R-19 R-13 0.217

X

0.90

0.83

CRRC PRODUCT ID 0850-0009X

WOOD FRAMED

RAFTER ROOF

CONCRETE

FURRING

METAL FRAMED

DEMISING WALL

DOORS

FLOOR

WALL-E

ADIABATIC

DEMISING

OPAQUE

METAL DOORS

CONCRETE SLAB

ON GRADE

-

-

16.80

-

-

-

-

R-0

-

-

-

-

-

-

0.700

-

-

-

0.650

IV.2 A22

METAL

IV.13 E5

IV.19 N17

0.167

0.049

IV.11 A300.153

IV.26 A1

IV.5 A2

-

ENVELOPE MANDATORY MEASURES:

INSTALLED INSULATING MATERIAL SHALL HAVE BEEN CERTIFIED BY THE MANUFACTURER TO COMPLY WITH

THE CALIFORNIA QUALITY STANDARDS FOR INSULATING MATERIAL PER §118.

ALL INSULATING MATERIALS SHALL BE INSTALLED IN COMPLIANCE WITH THE FLAME SPREAD RATING AND

SMOKE DENSITY REQUIREMENTS OF SECTIONS 2602 AND 707 OF THE CBC.

ALL EXTERIOR JOINTS AND OPENINGS IN THE BUILDING ENVELOPE THAT ARE OBSERVABLE SOURCES OF AIR

LEAKAGE SHALL BE CAULKED, GASKETED, WEATHER-STRIPPED OR OTHERWISE SEALED PER §117.

SITE CONSTRUCTED DOORS, WINDOWS AND SKYLIGHTS SHALL BE CAULKED BETWEEN THE UNIT AND THE

BUILDING, AND SHALL BE WEATHER-STRIPPED (EXCEPT FOR UNFRAMED GLASS DOORS AND FIRE

DOORS).

MANUFACTURED DOORS AND WINDOWS INSTALLED SHALL HAVE AIR INFILTRATION RATES CERTIFIED BY THE

MANUFACTURER PER §116(a)1. MANUFACTURED FENESTRATION PRODUCTS MUST BE LABELED FOR

U-FACTOR ACCORDING TO NFRC PROCEDURES.

DEMISING WALL INSULATION (R-13) SHALL BE INSTALLED IN ALL OPAQUE PORTIONS OF FRAMED WALLS

(EXCEPT DOORS).

INSULATION MAY NOT BE INSTALLED DIRECTLY OVER SUSPENDED CEILINGS.

COOL ROOFS MUST BE TESTED AND LABELED BY THE COOL ROOF RATING COUNCIL (CRRC). THE CRRC TEST

PROCEDURE IS DOCUMENTED IN CRRC-1 AND INCLUDES TESTS FOR BOTH REFLECTANCE AND

EMITTANCE AND COOL ROOFS SHALL BE INSTALLED PER §118 ON ALL OPAQUE PORTIONS OF THE

ROOFING.

ROOF INSULATION (R-19) SHALL BE INSTALLED IN ALL OPAQUE PORTIONS OF FRAMED ROOFS (EXCEPT

SKYLIGHTS, MECHANICAL PENATRATIONS, ETC.).

EXTERIOR WALL FURRING INSULATION (R-13) SHALL BE INSTALLED IN ALL OPAQUE PORTIONS OF FRAMED

FURRING WALLS (EXCEPT DOORS).](https://image.slidesharecdn.com/chino-151018052527-lva1-app6891/75/Farmers-PDC-Chino-CA-11-2048.jpg)