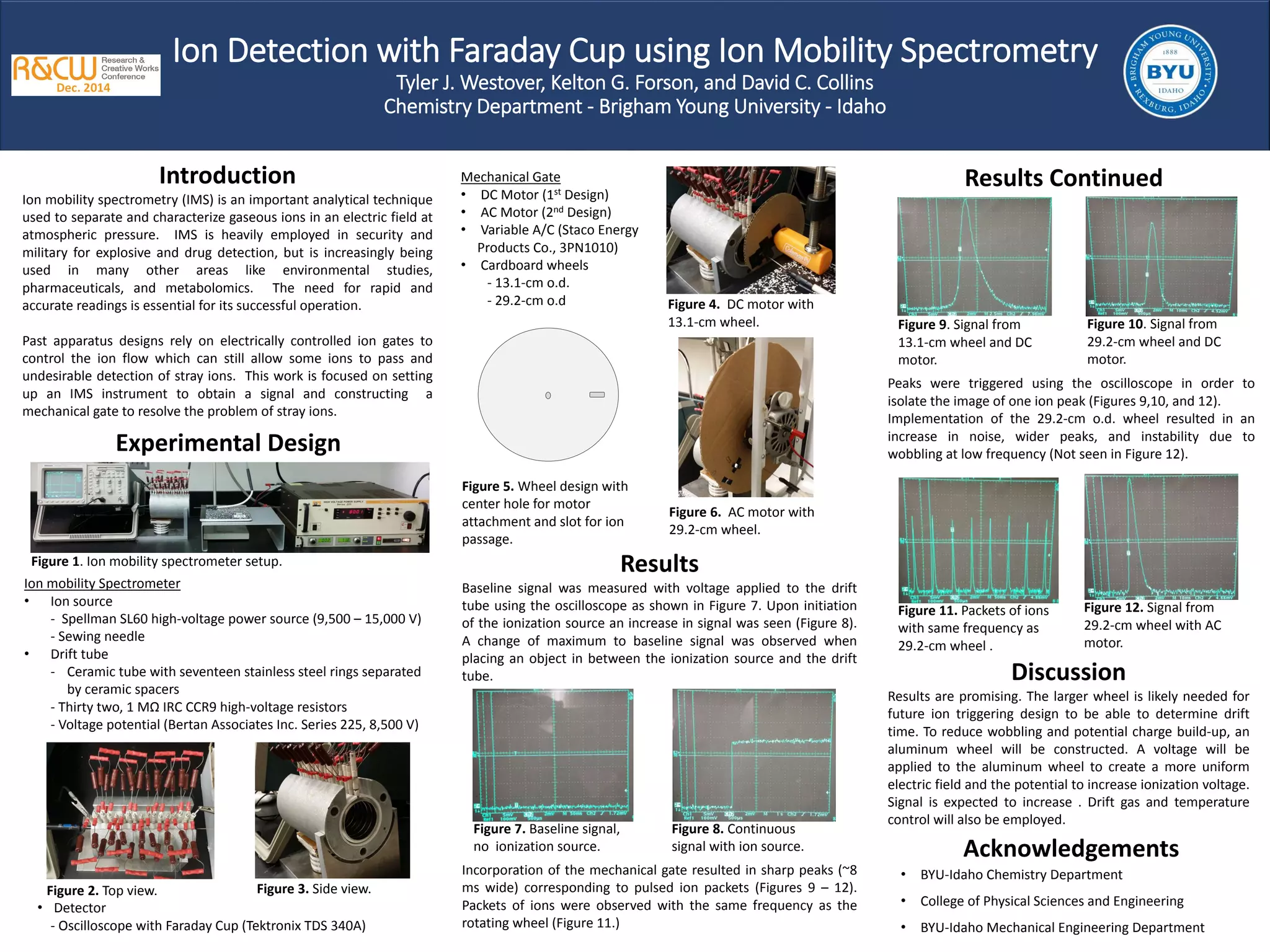

Ion detection with Faraday cup using ion mobility spectrometry. An ion mobility spectrometer was designed with an ion source, drift tube, and detector. Baseline signals were measured and increased upon ionization source initiation. Incorporating a mechanical gate of cardboard wheels rotated by DC or AC motors resulted in sharp ion packet peaks corresponding to the wheel's rotation frequency, resolving issues of stray ions passing uncontrolled ion gates. Future work will employ a larger aluminum wheel for improved ion triggering, higher ionization voltages, drift gas temperature control, and reduced wheel wobbling.