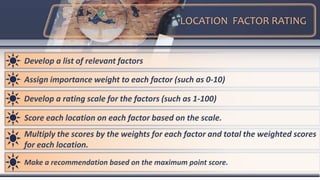

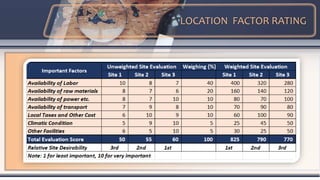

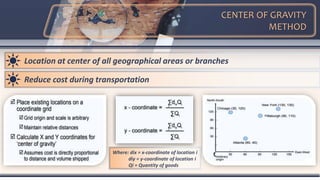

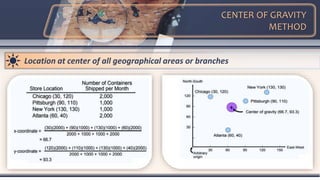

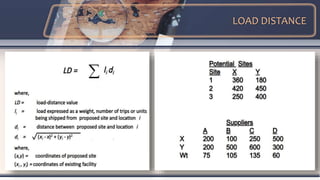

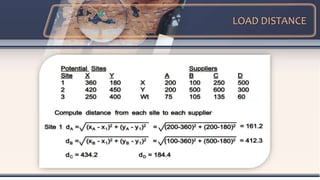

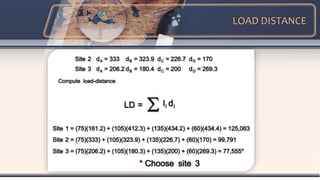

The document discusses facility location analysis. It describes facility location as identifying the best geographic location for production or services. Key factors in choosing a location include reducing costs, qualifying workforce, and complying with government policies. The main steps are developing selection criteria, analyzing qualitative and quantitative data, researching competing locations, considering incentives, and finalizing the decision. Location analysis techniques covered include factor rating, center of gravity, and load distance methods.