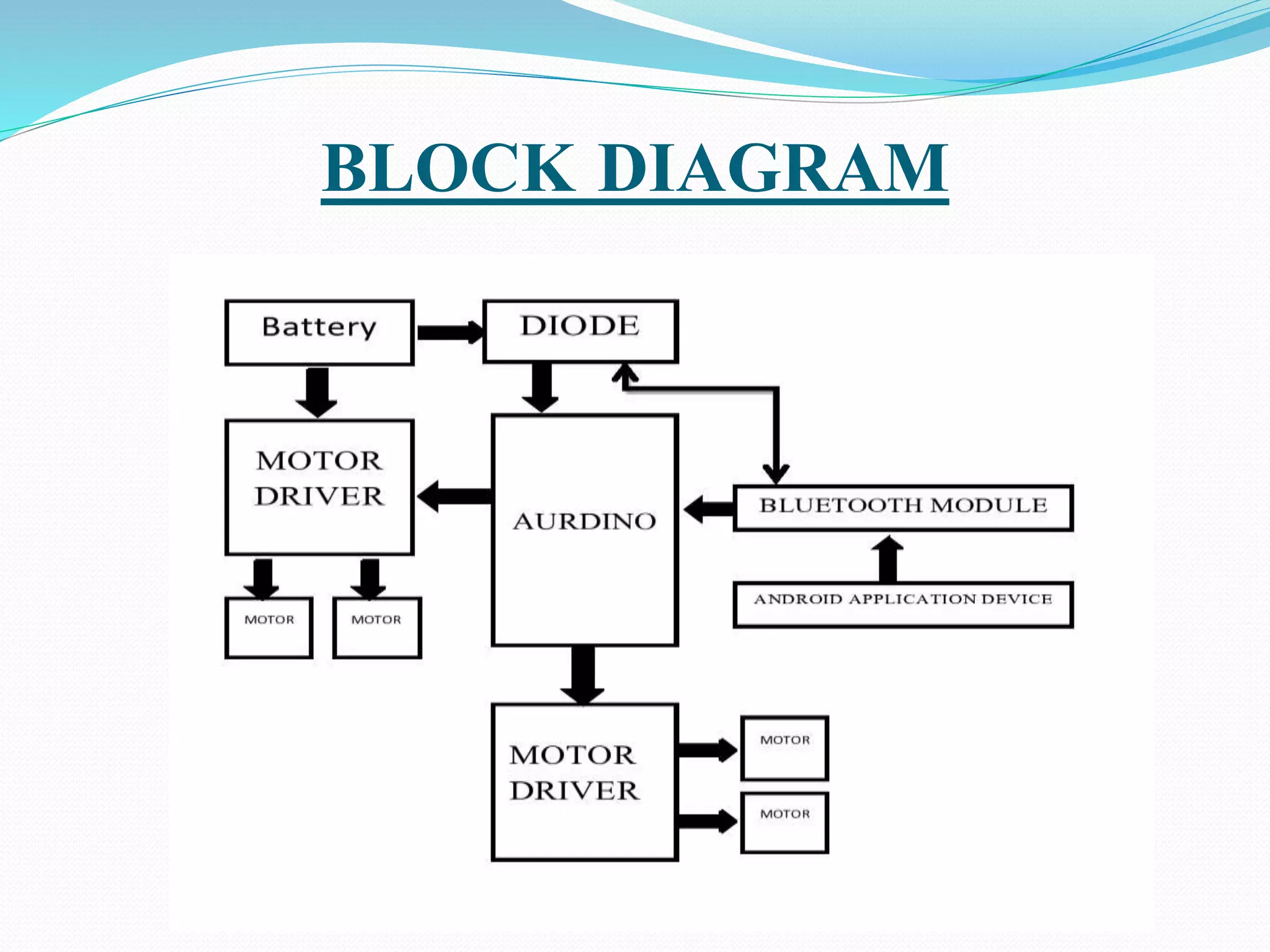

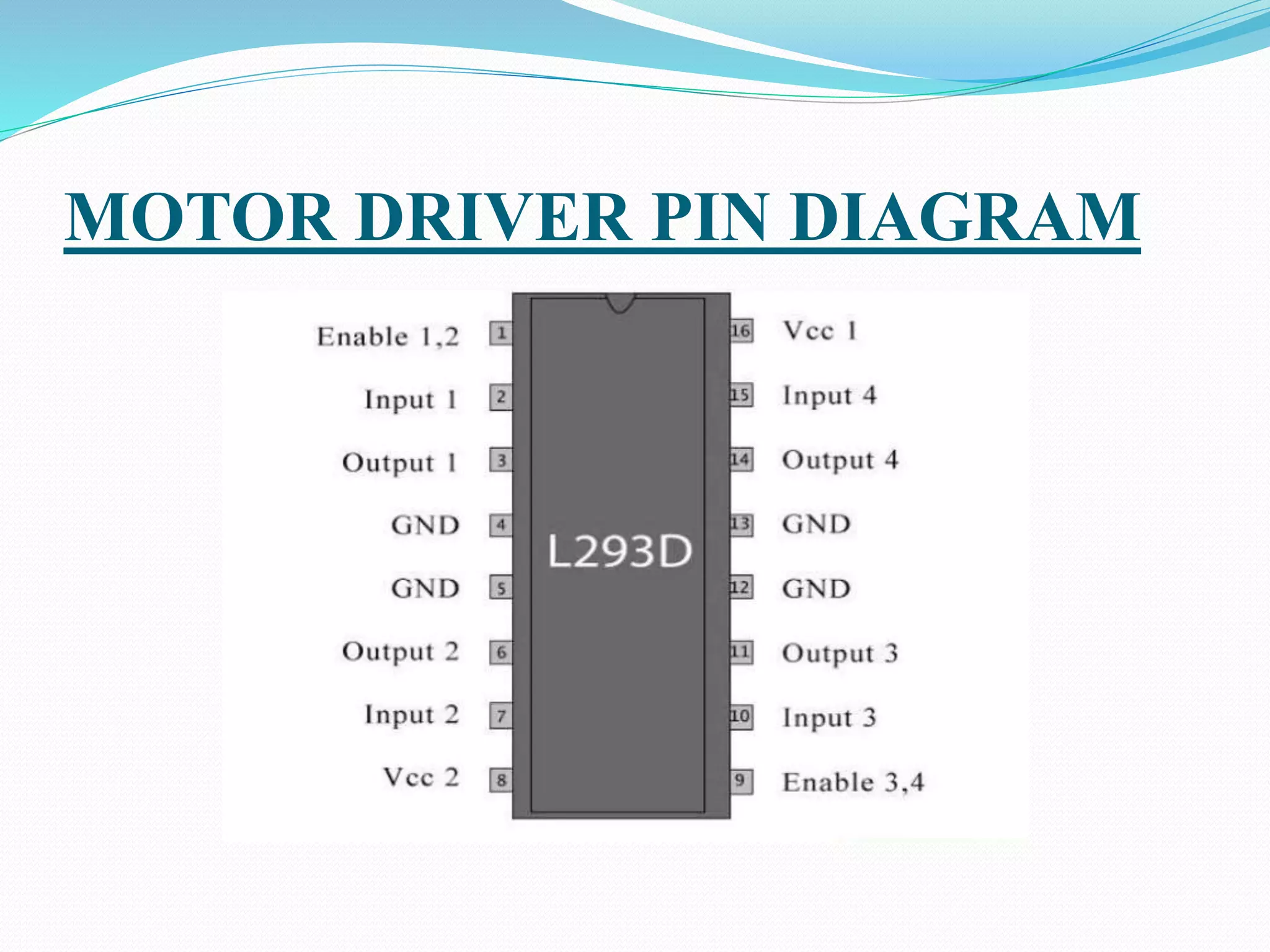

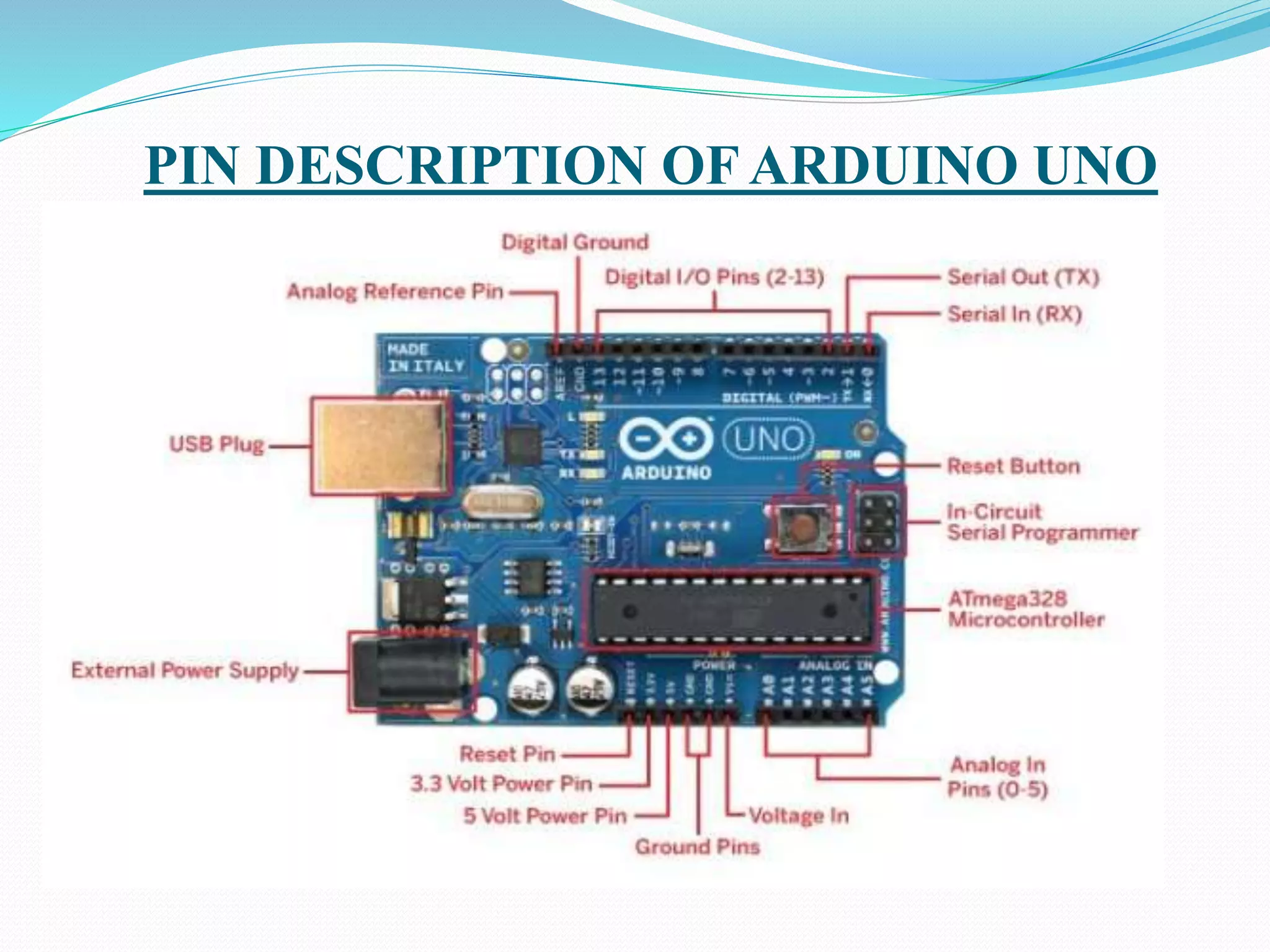

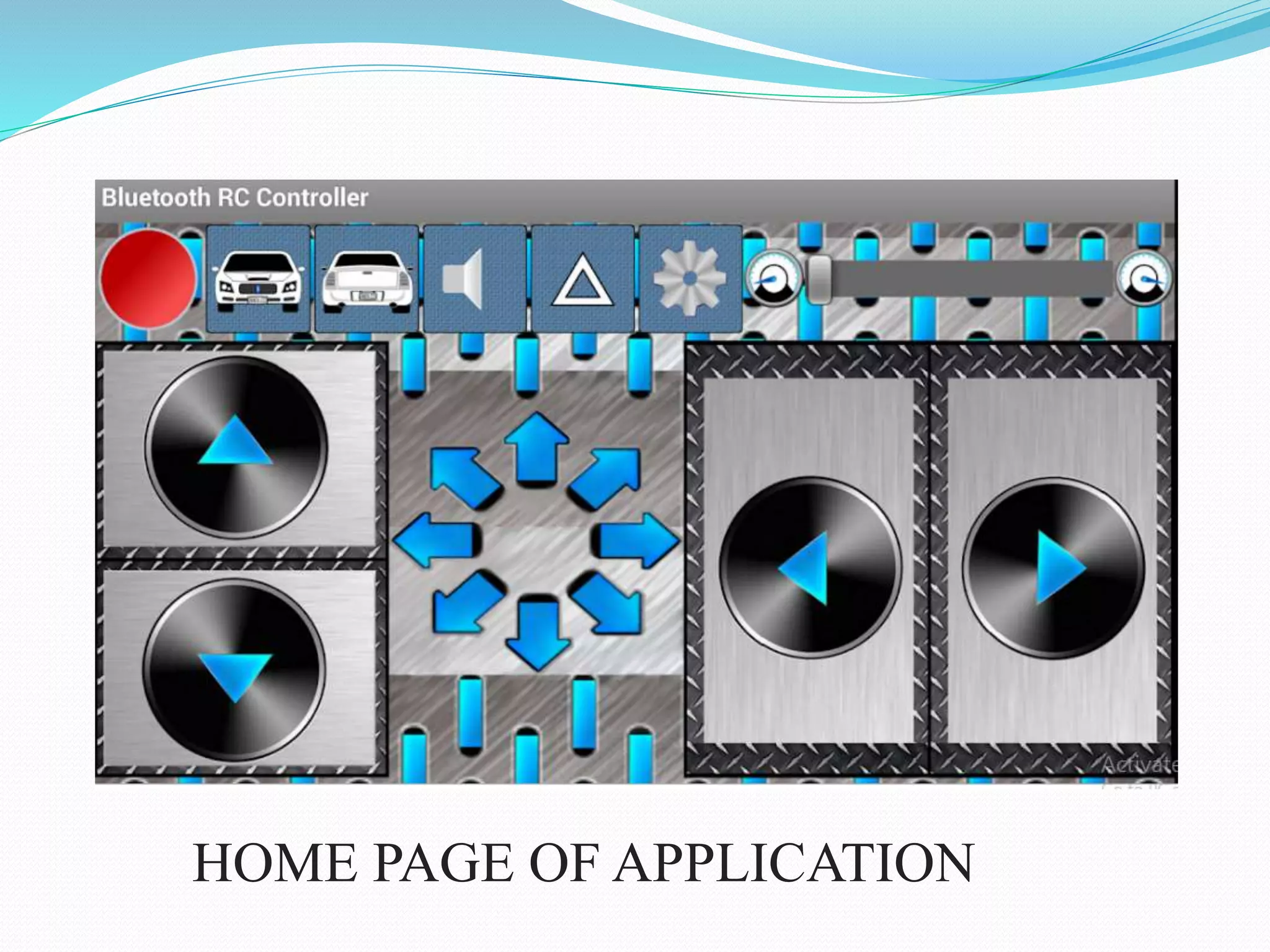

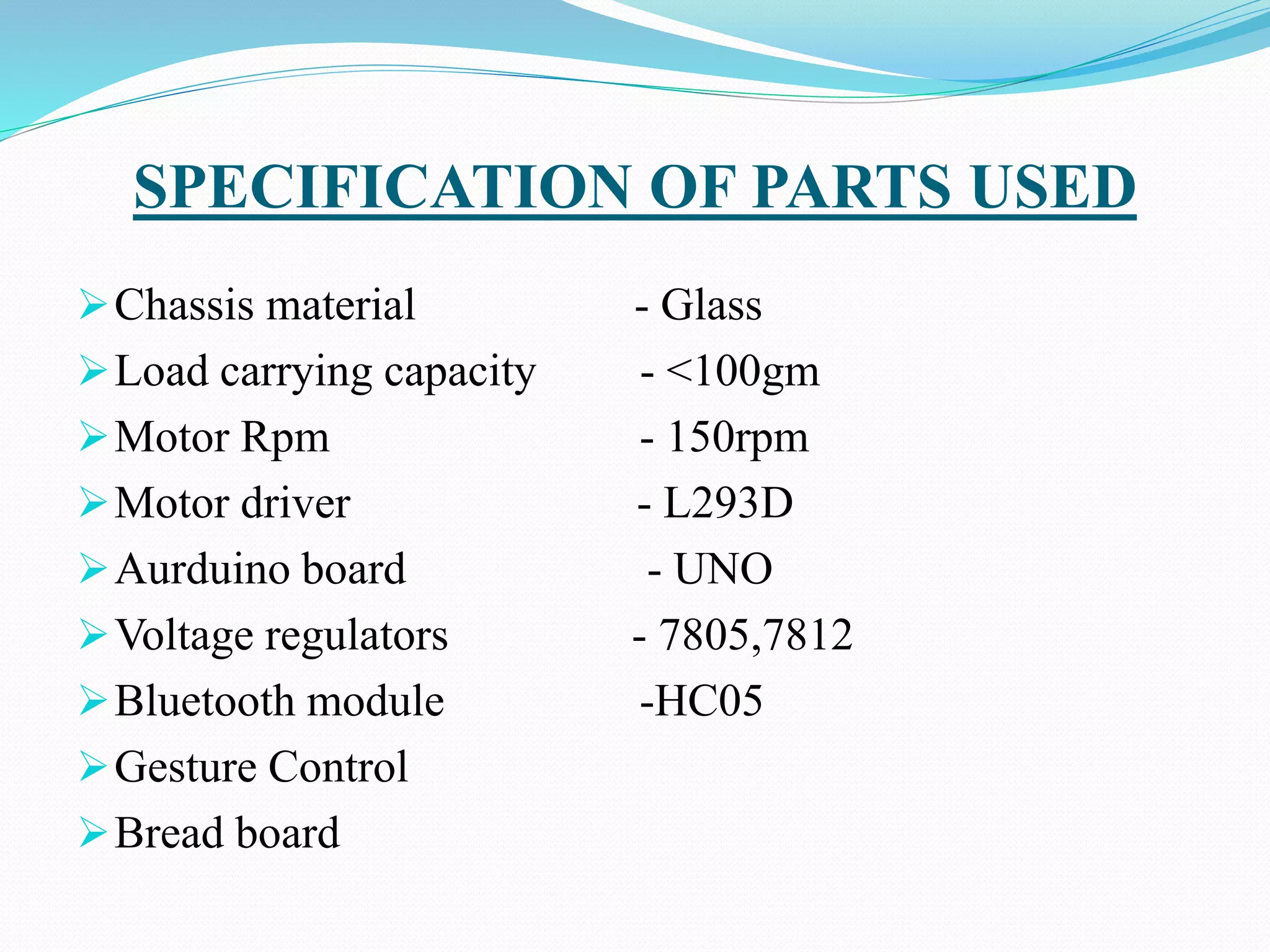

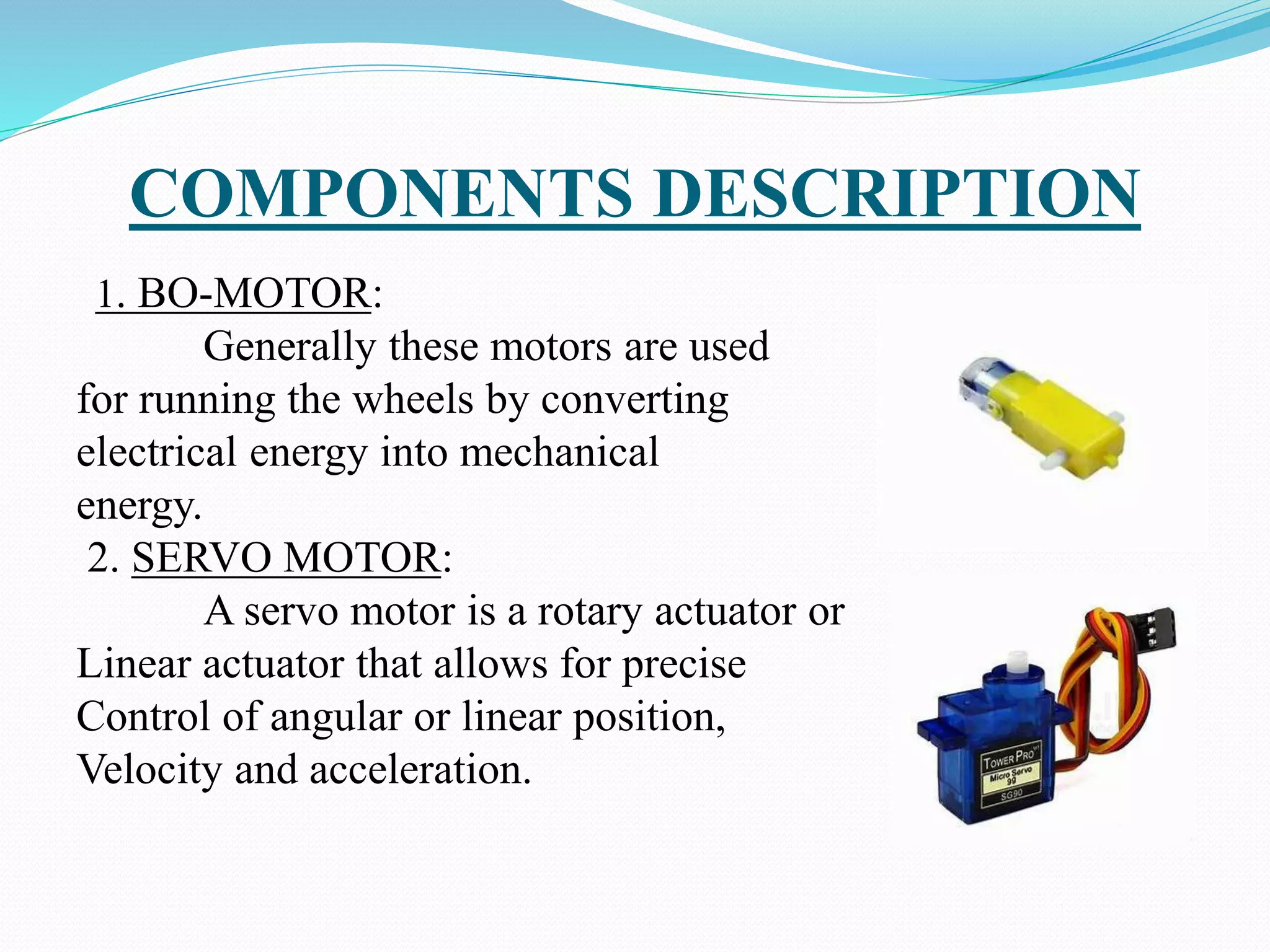

This document describes a project to design a remotely controlled robotic vehicle with an arm. The objectives are to allow remote control via Bluetooth and synchronous movement of the vehicle and arm. The proposed method is to combine the vehicle and arm for semi-automated operation. Key components include an Arduino board, motor drivers, Bluetooth module, and chassis. The arm and vehicle can be controlled through a mobile app. Applications include pick and place, material handling, and industrial tasks like welding. Advantages over manual labor include speed, accuracy, reliability and affordability.