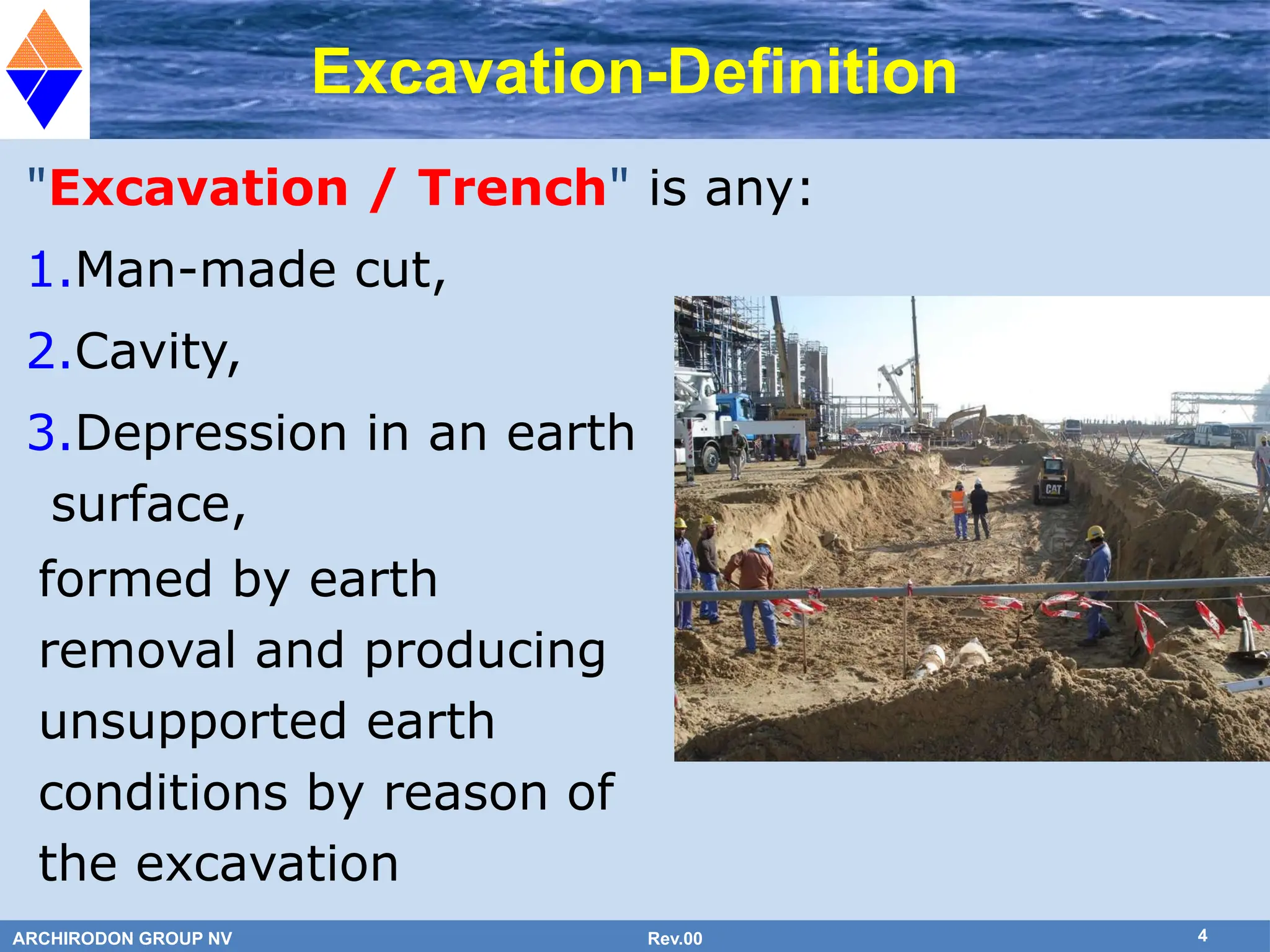

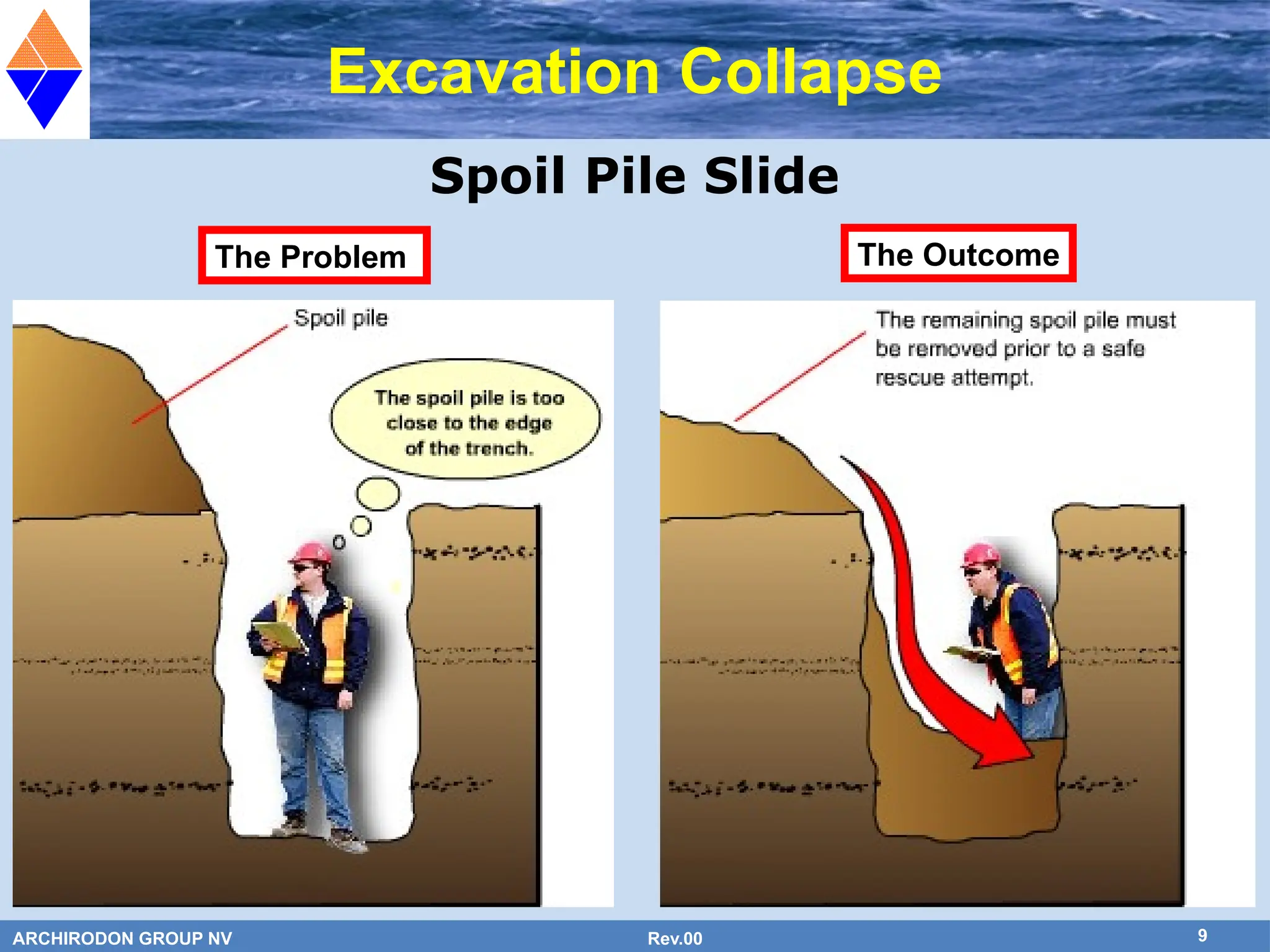

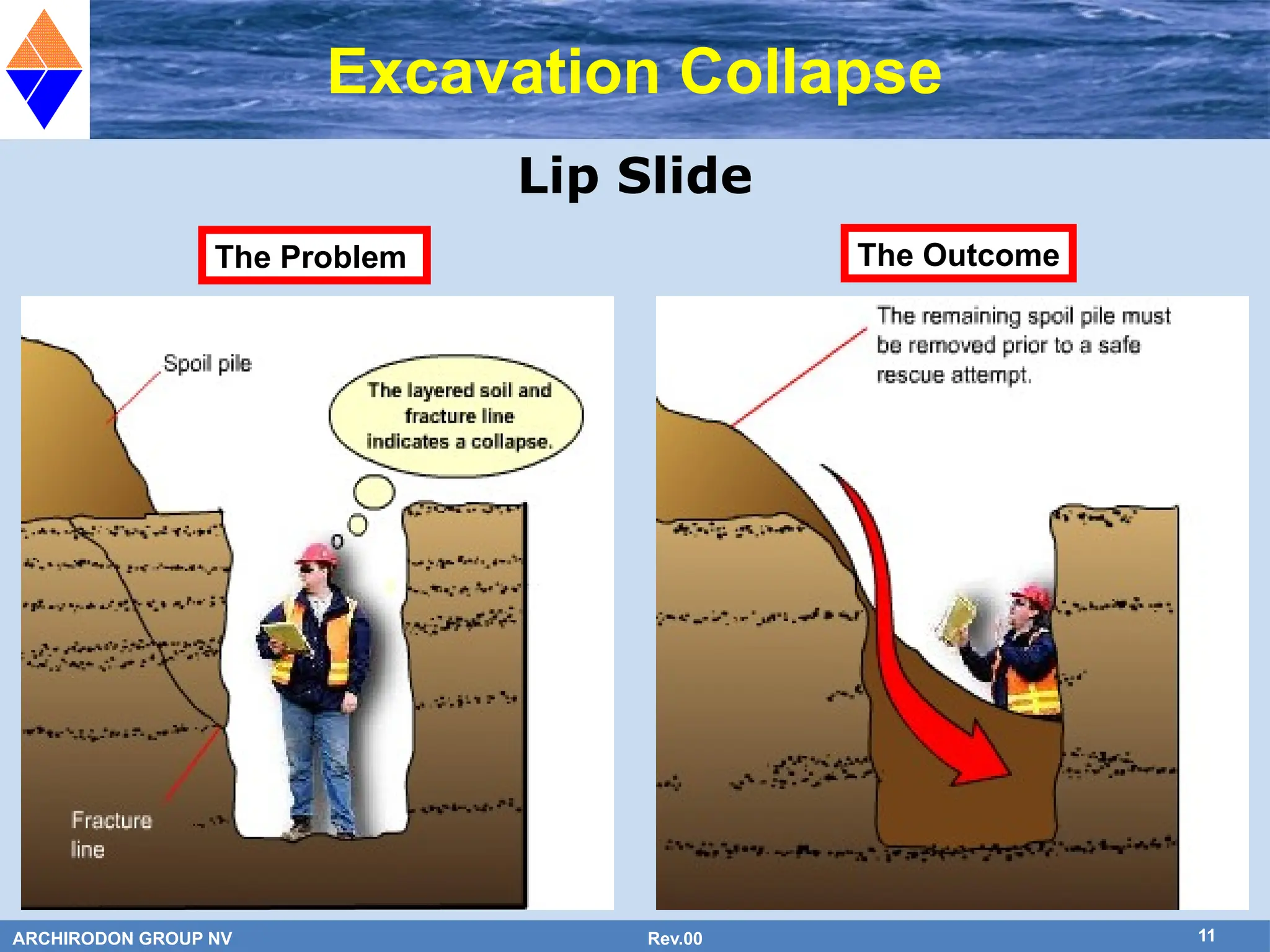

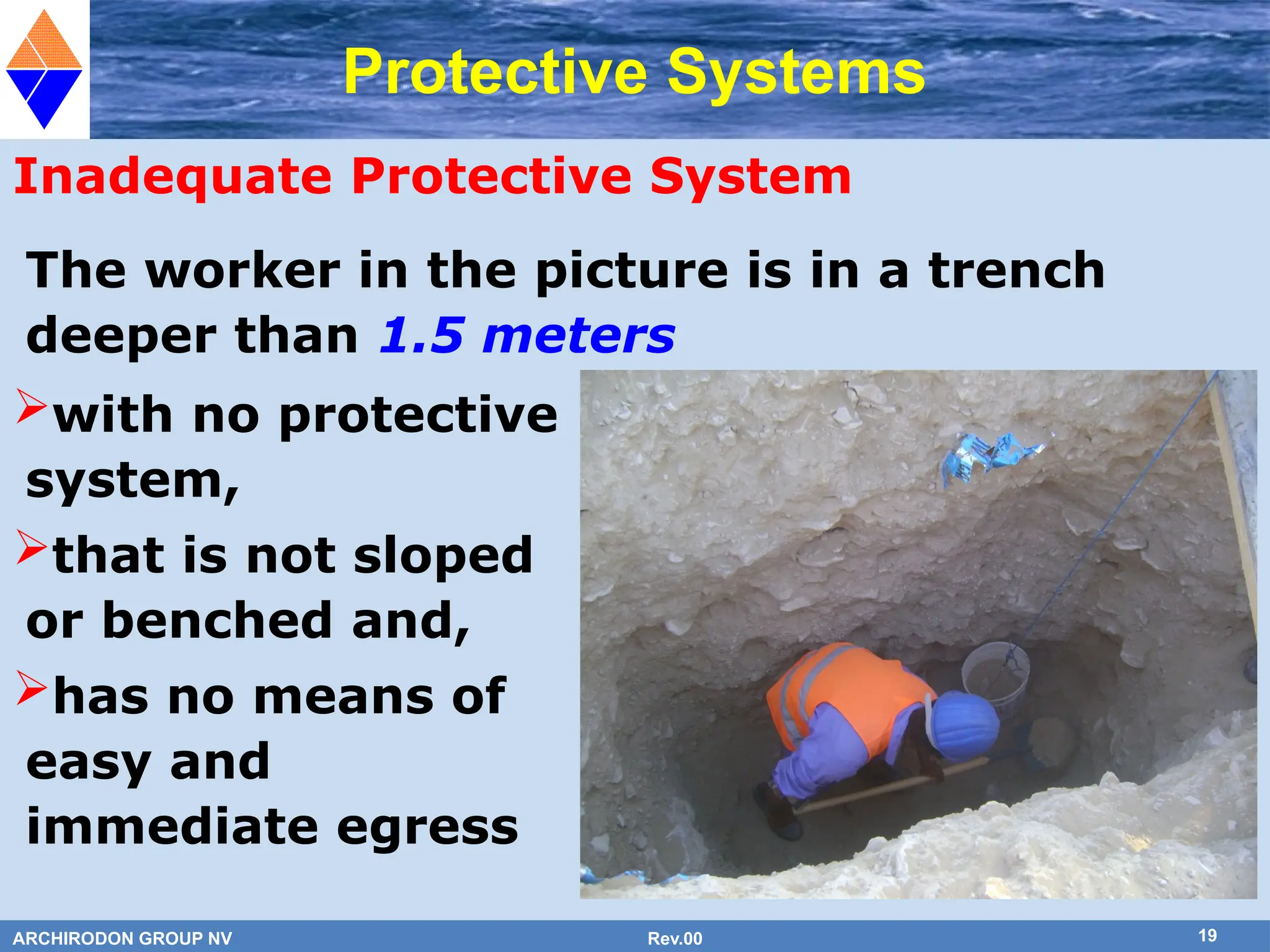

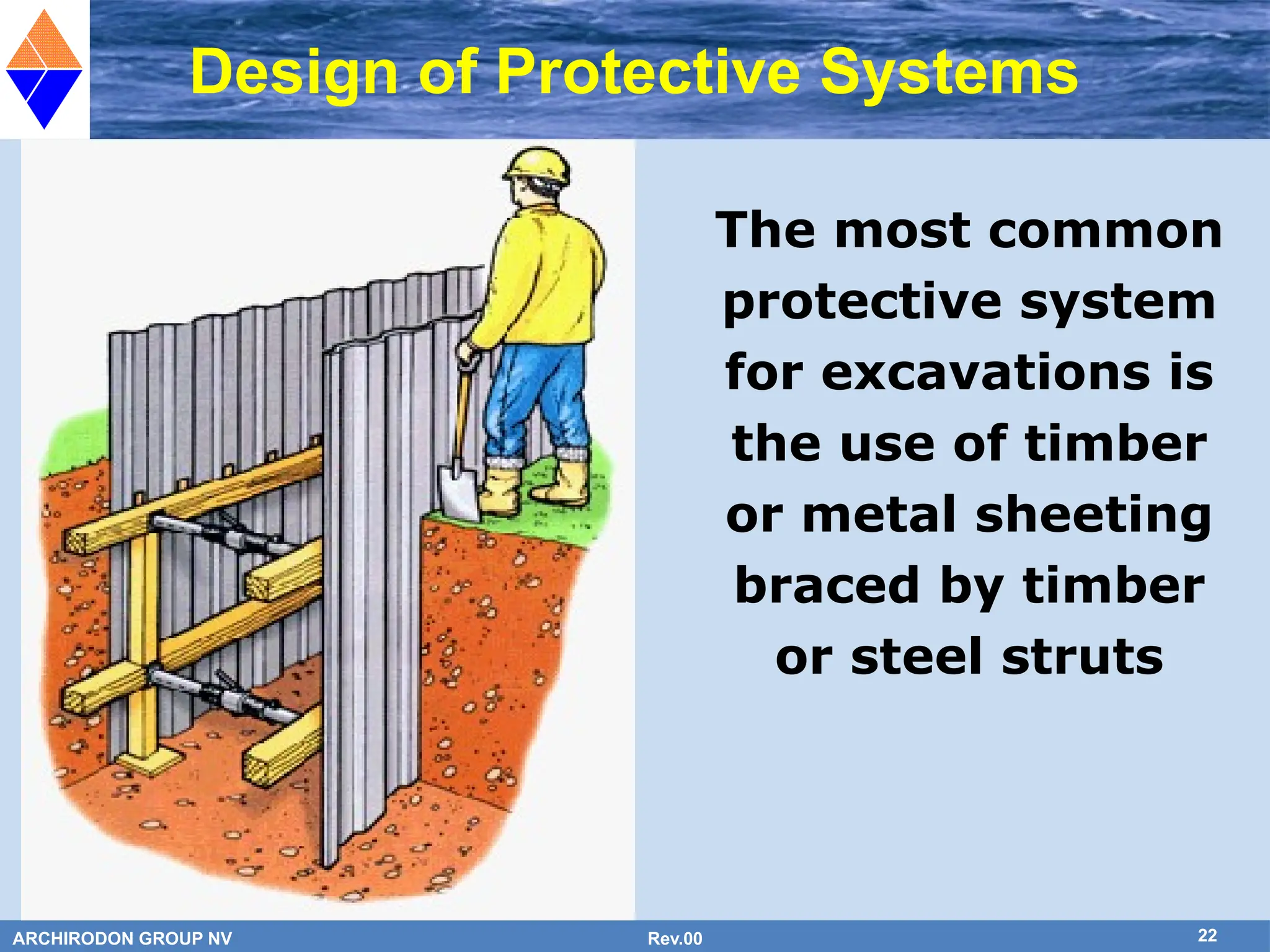

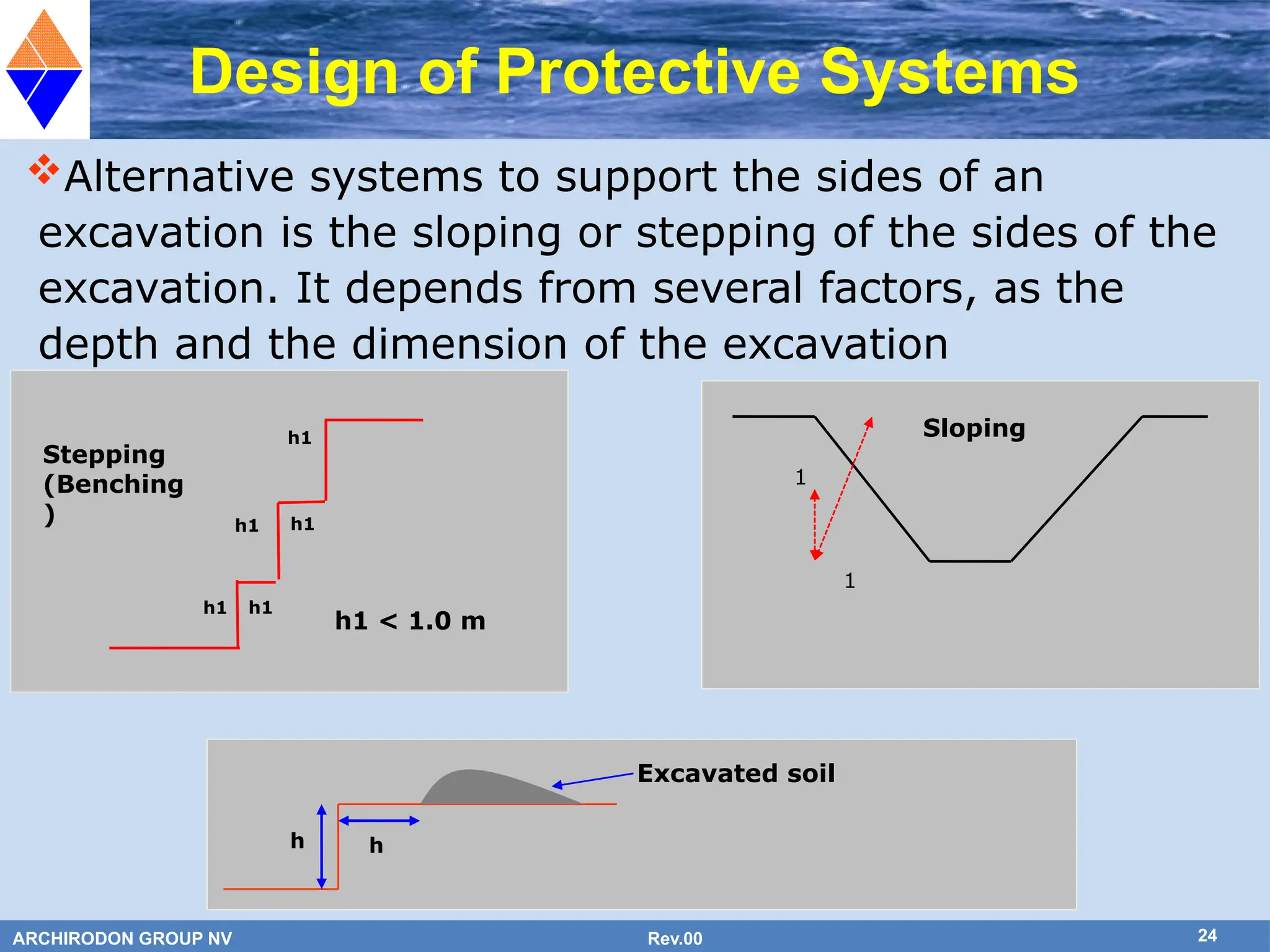

The document outlines essential health and safety training related to excavations, including definitions, hazards, planning, and protection measures for workers. Key topics include risks of collapse, protective systems, and the importance of proper access and egress for worker safety. It emphasizes the need for hazard assessments, proper identification of underground services, and adherence to safety protocols to prevent accidents.