This document provides an overview and timeline for an ERP implementation project. It includes:

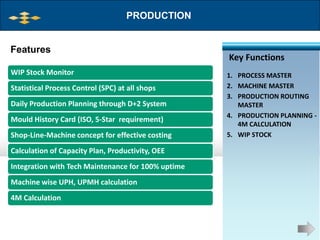

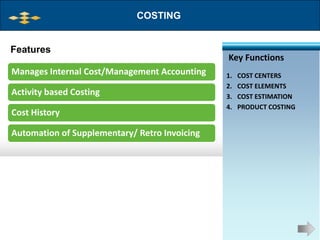

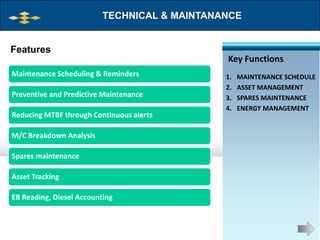

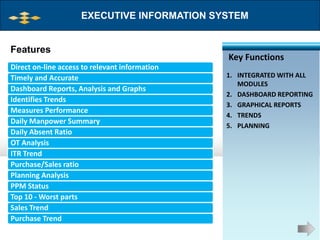

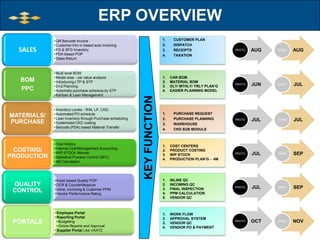

1. An overview of the key ERP modules to be implemented, including sales, production planning, materials/purchasing, quality control, and portals.

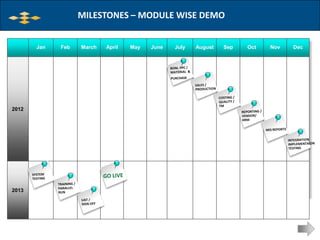

2. A schedule of CFT (Cross Functional Team) meetings to collect requirements and demo prototypes for each module across June-November 2012.

3. Details of the CFT meeting scope, which involves confirming processes/flows, identifying requirements, risks, business rules and master data for each module.

4. Milestones showing targeted demo dates for the main modules between June-December 2012.

The document provides a high-level snapshot of the

![B.O.M.

BOM Creation Process

Development Person Master & BOM Responsibility &

IT Team Leader Process Description Output

& Manager Person (IT) Approval

1.Deliver information about new BOM Change Developmen

1 development or new ECO Application t Member

Information of & & Manager

New (Developer delivers sourcing list, BOM

Development application form to IT person in-charge of Sourcing List

/EO Change 3 Master)

2

Receive Review BOM BOM Change Master

2.Check for Consistency and

inquiry of Change Application

Application Completeness after receiving BOM Person (IT)

BOM creation

& Approval Form & application form and sourcing list.

Yes

Approval

If errors are found, Return the paper to

Invalid NO developer,

Sourcing List

[Return]

Sourcing list and BOM change application

form must have Material details & other

required information about that.

3. IT Team Leader verifies BOM IT Team

application form and sourcing list. Manager

Rewritie sourcing NO

list/Check BOM & Educate 4.In accordance with BOM application BOM Change IT Team

Error form, Create Material Master & BOM Information Member

(Master)

5.The IT member is responsible to IT Team

5 create Master and BOM informs to related Member

Inform 4

Completion of teams about the creation / change in

Yes

BOM Creation MASTER & BOM BOM.

[Development,Ma Creation

terials,Sales,Cost Concerned

] Other team members should check the Team

BOM Module that the BOM is updated as Members

requested](https://image.slidesharecdn.com/erpmdreport-120704013340-phpapp02/85/Erp-md-report-13-320.jpg)