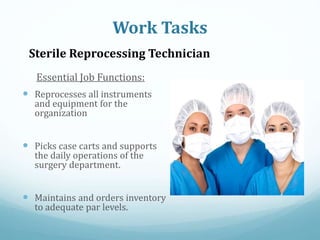

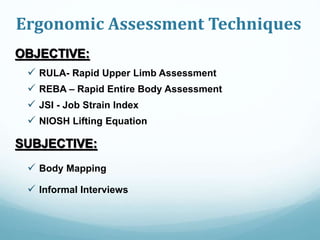

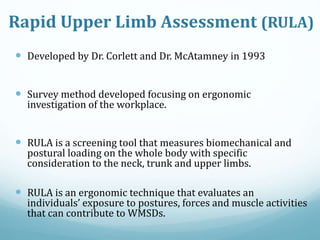

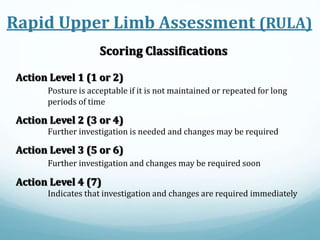

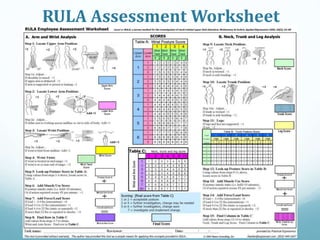

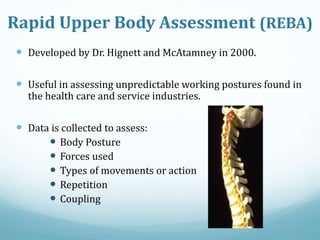

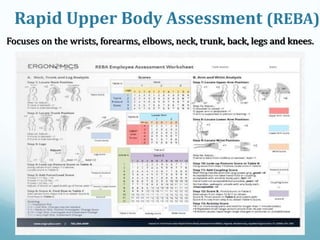

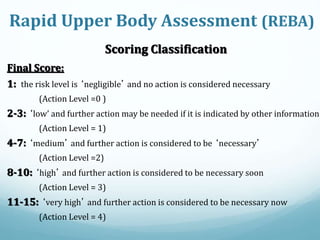

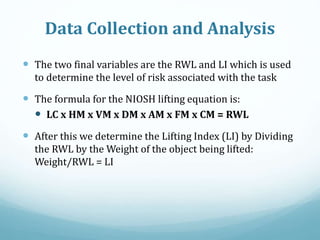

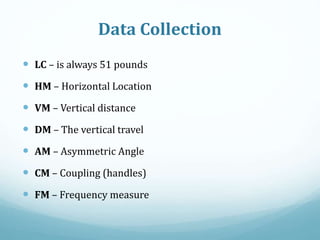

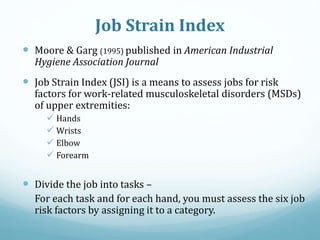

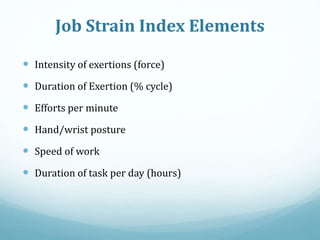

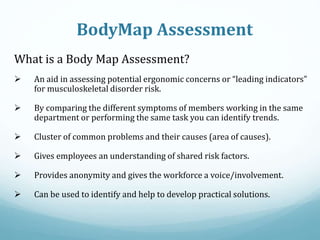

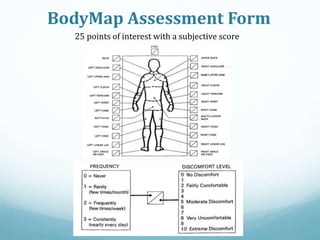

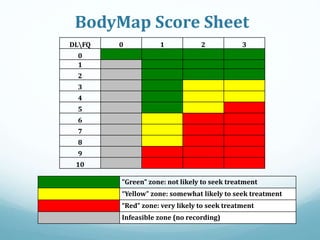

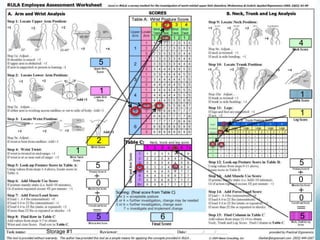

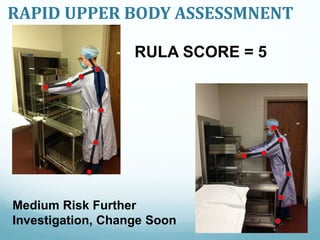

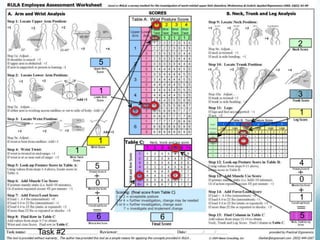

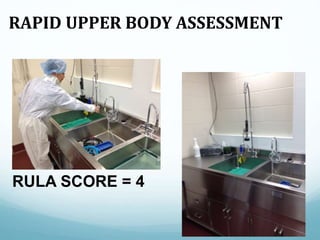

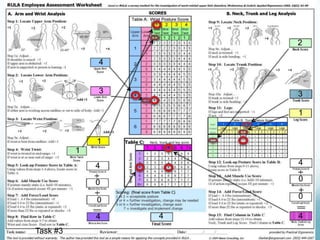

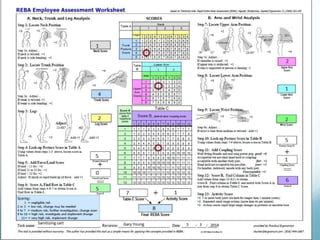

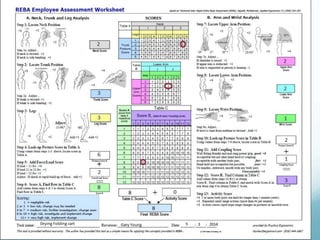

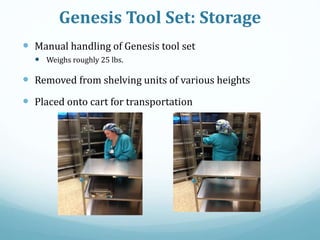

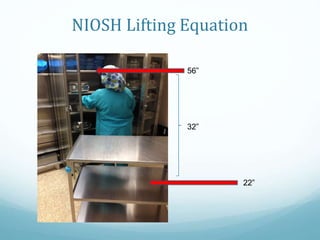

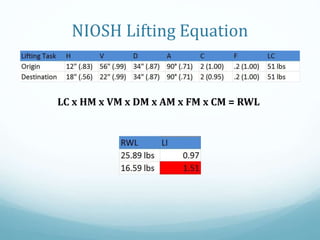

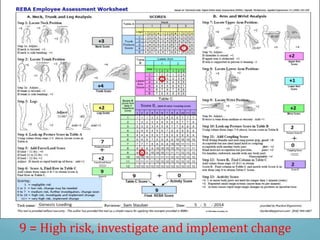

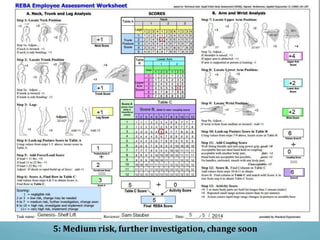

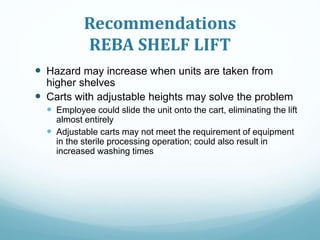

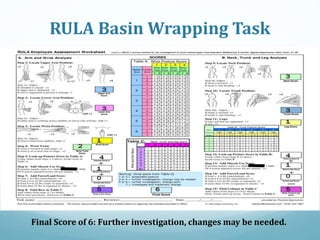

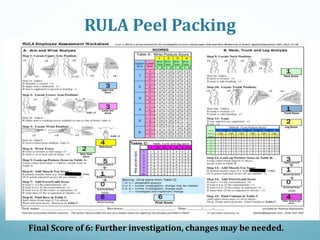

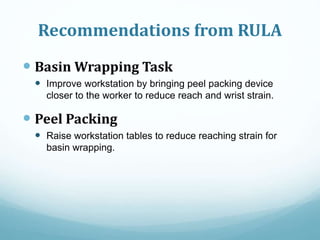

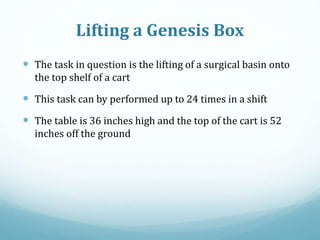

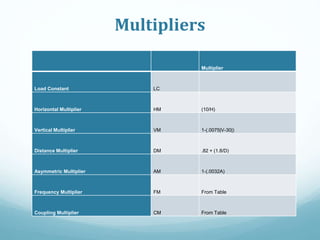

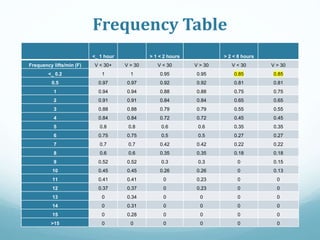

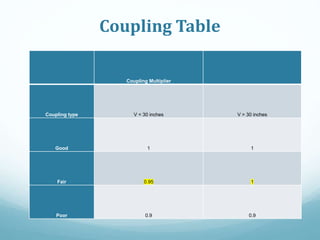

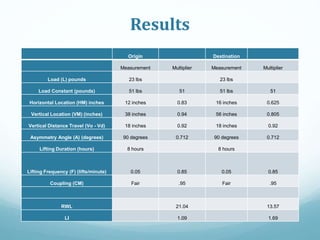

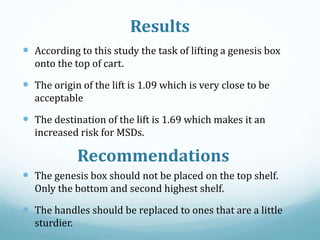

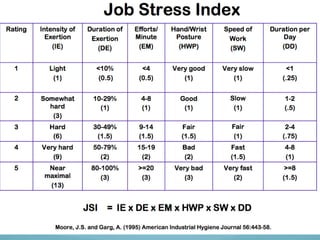

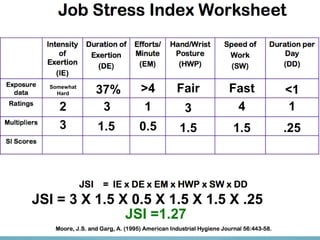

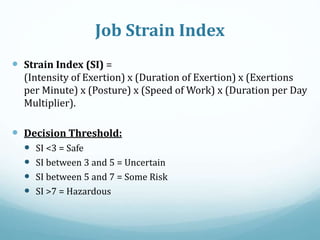

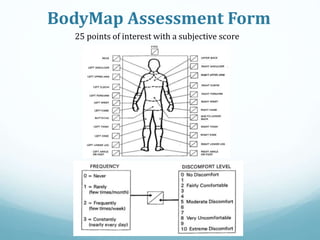

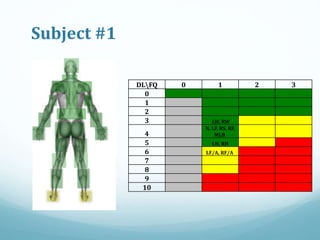

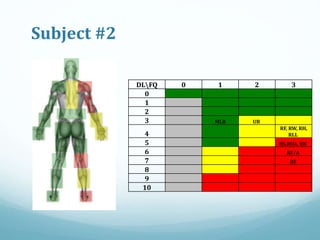

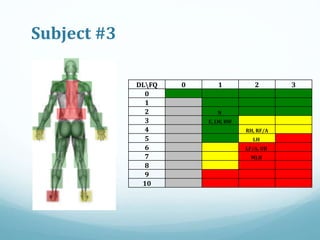

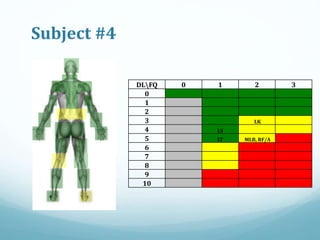

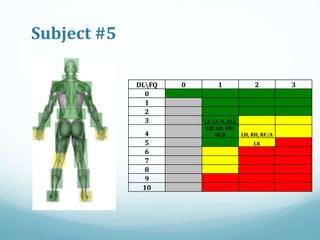

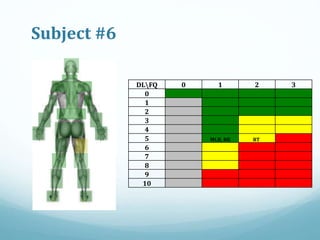

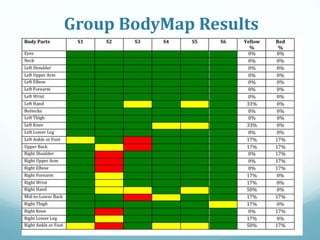

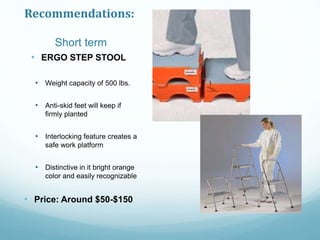

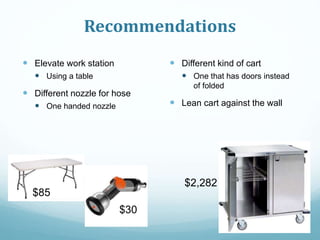

This document summarizes an ergonomic evaluation of a sterile processing department. It includes an agenda, background on work-related musculoskeletal disorders and injury rates in healthcare, an overview of ergonomic assessment tools like RULA, REBA, and NIOSH Lifting Equation. The document then describes job tasks analyzed like storage, processing, and cart washing. Assessment results for specific tasks show risk levels from medium to very high. Recommendations include changes to workstations, adjustable cart heights, and proper lifting techniques to reduce ergonomic risks.