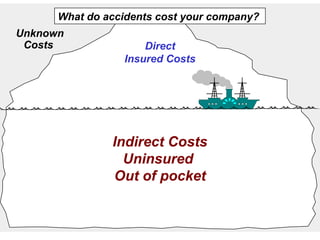

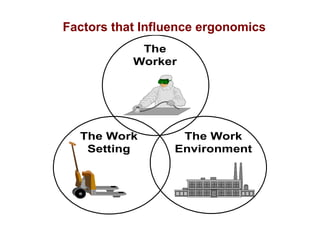

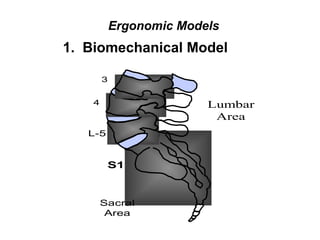

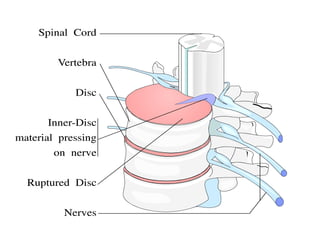

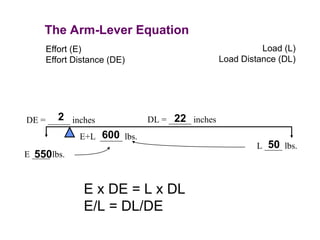

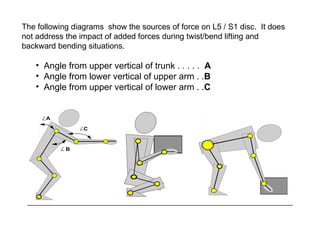

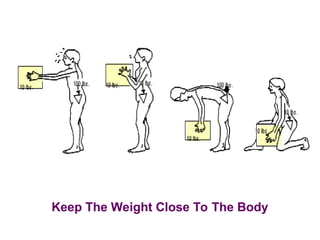

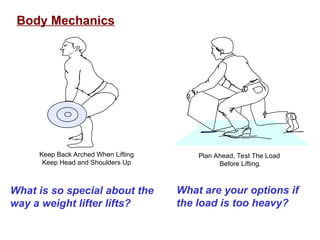

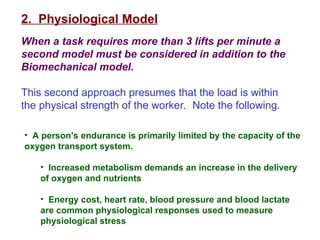

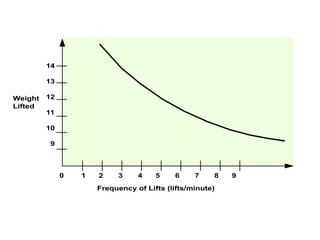

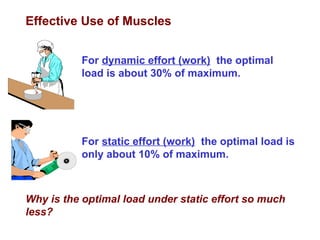

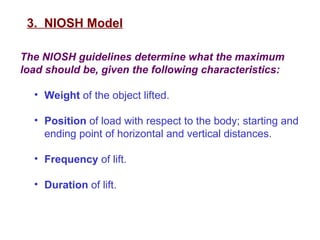

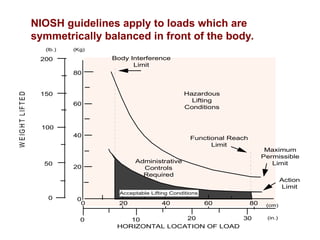

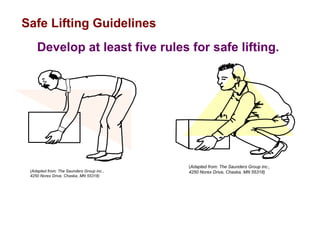

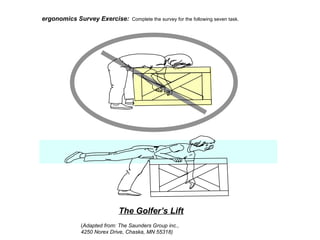

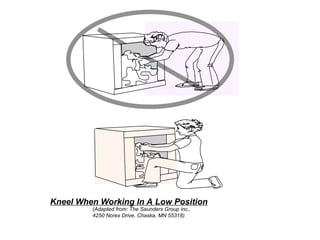

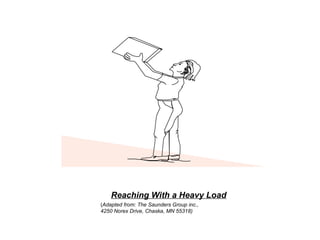

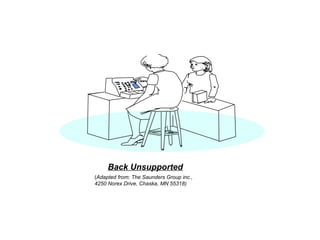

The document outlines a workshop on ergonomics, aiming to equip participants with skills to identify ergonomic injury costs, apply ergonomic principles, and implement safe lifting techniques. It discusses the definition of ergonomics, factors influencing ergonomic safety, and provides guidelines for manual material handling and back injury prevention. Additionally, it includes models for analyzing lifting and methods to reduce risks associated with lifting tasks.