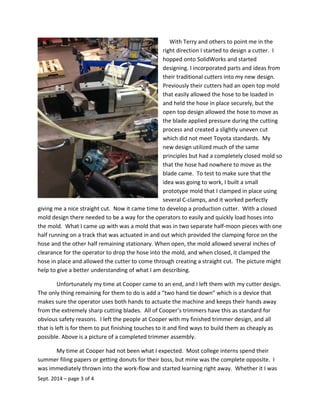

The author had an internship at Cooper Standard Automotive where he was immediately involved in improvement projects. In his first week, he participated in a Kaizen event to streamline a work cell, which involved moving equipment to reduce travel distances and improve ergonomics. He created new storage racks for dies and hoses to make the operators' jobs easier. Later, he designed and built a new hose cutting machine to replace an unreliable robot, incorporating a closed mold to ensure straight cuts meeting Toyota's standards. The author gained valuable hands-on experience beyond typical intern tasks like filing.