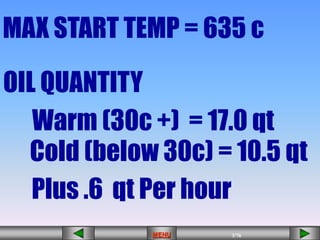

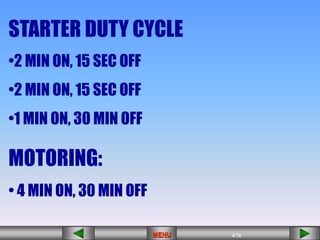

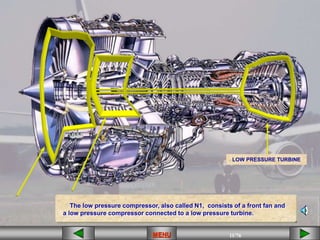

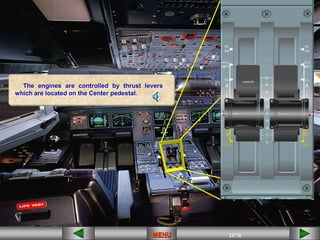

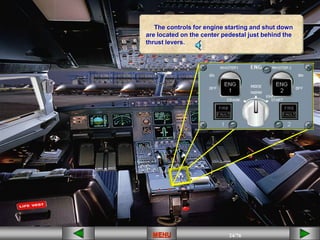

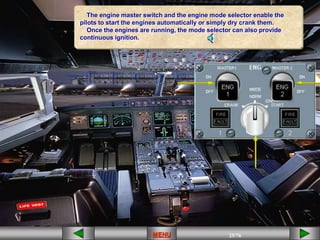

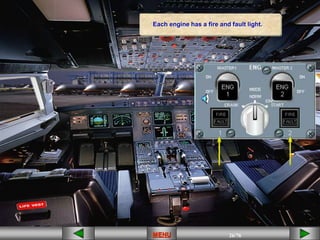

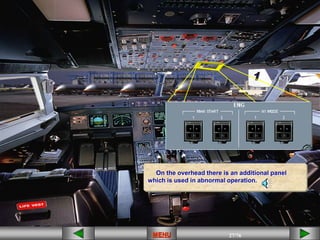

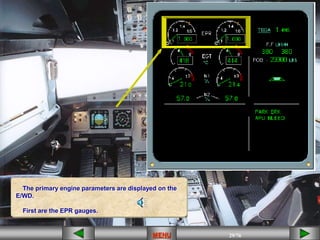

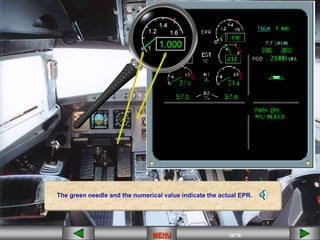

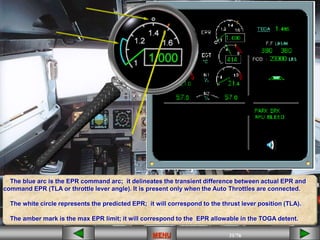

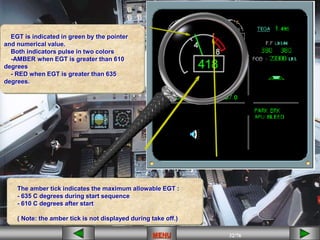

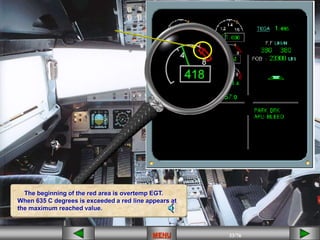

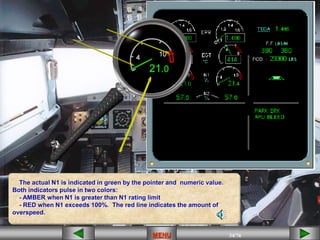

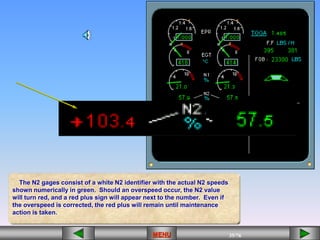

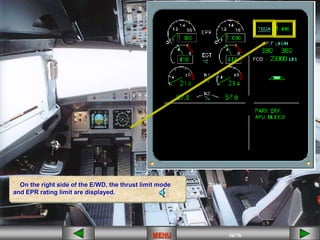

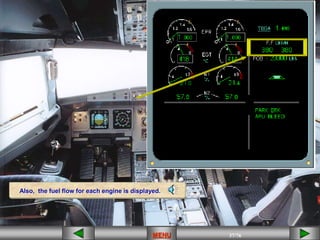

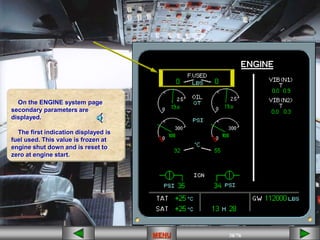

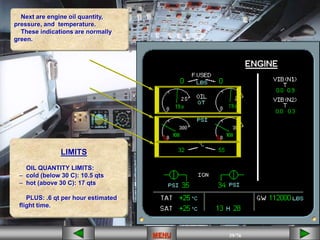

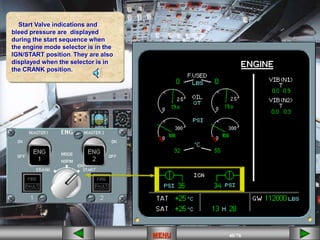

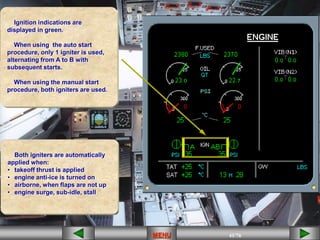

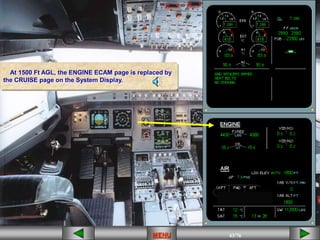

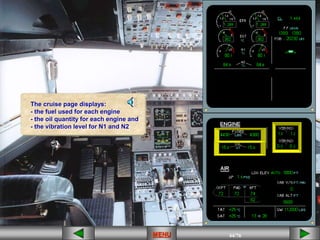

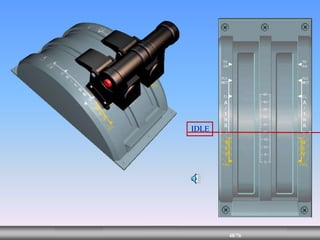

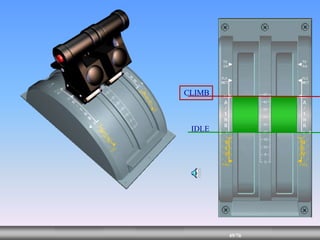

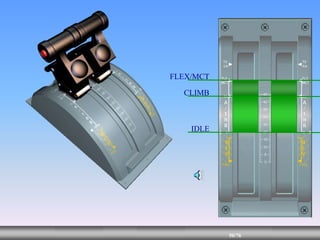

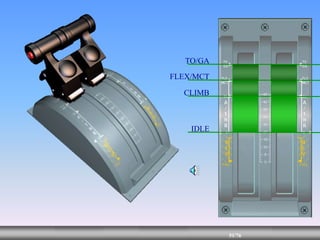

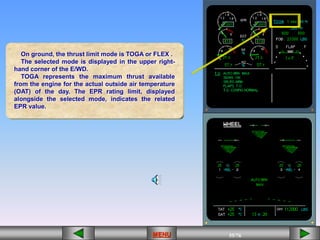

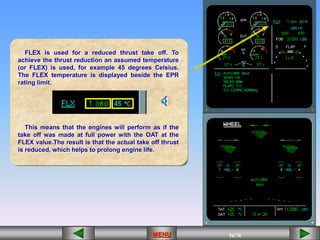

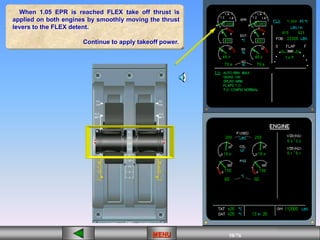

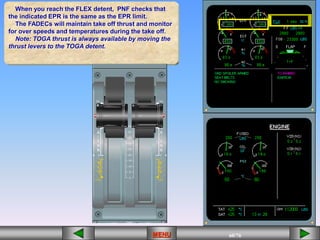

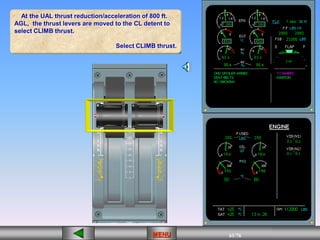

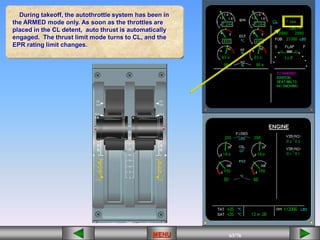

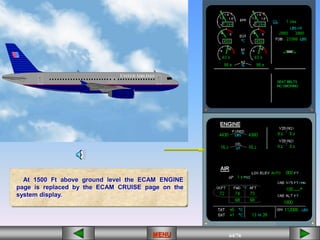

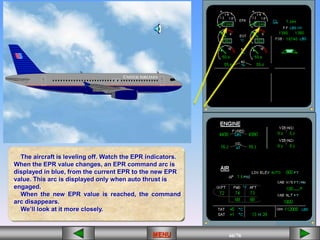

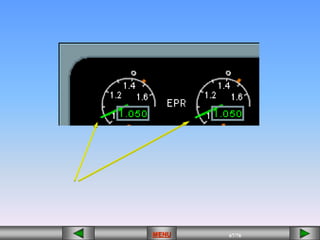

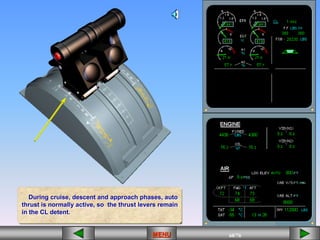

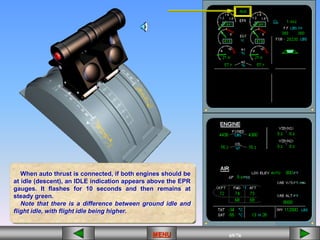

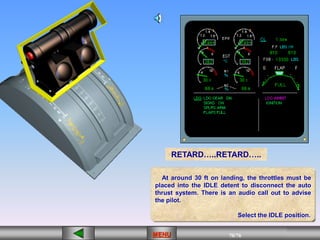

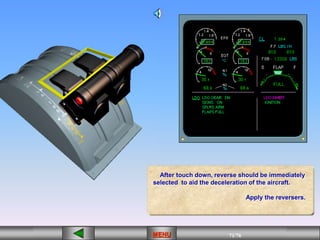

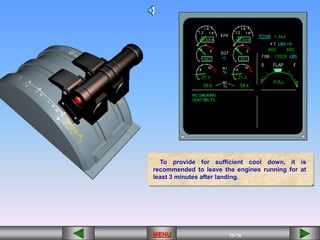

The document provides information about the operation and instrumentation of the International Aero Engines V2500 engines used on the Airbus A320 family. It details engine components, controls, displays, and procedures for takeoff, climb, and cruise. Key steps include selecting the desired thrust limit mode, such as TOGA for maximum takeoff thrust or FLEX for reduced thrust takeoff, then using the thrust levers or autothrottle to achieve and maintain the appropriate power levels during different phases of flight.