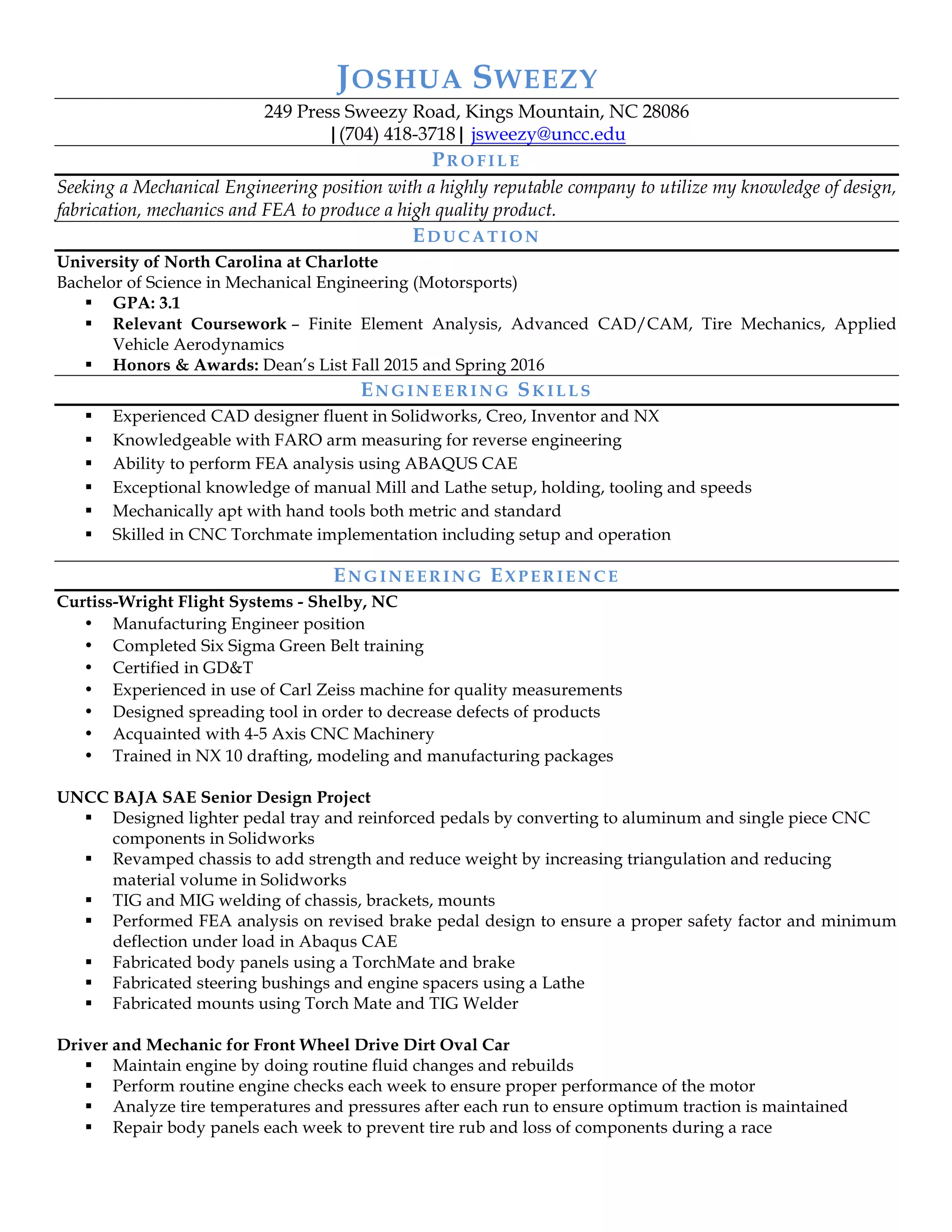

Joshua Sweezy is seeking a mechanical engineering position and has a Bachelor of Science in Mechanical Engineering from the University of North Carolina at Charlotte. He has experience as a manufacturing engineer at Curtiss-Wright Flight Systems where he completed Six Sigma Green Belt training and CAD/CAM skills. For his senior design project, he designed and fabricated components for a BAJA car using CAD software, FEA analysis, welding, and CNC machining.