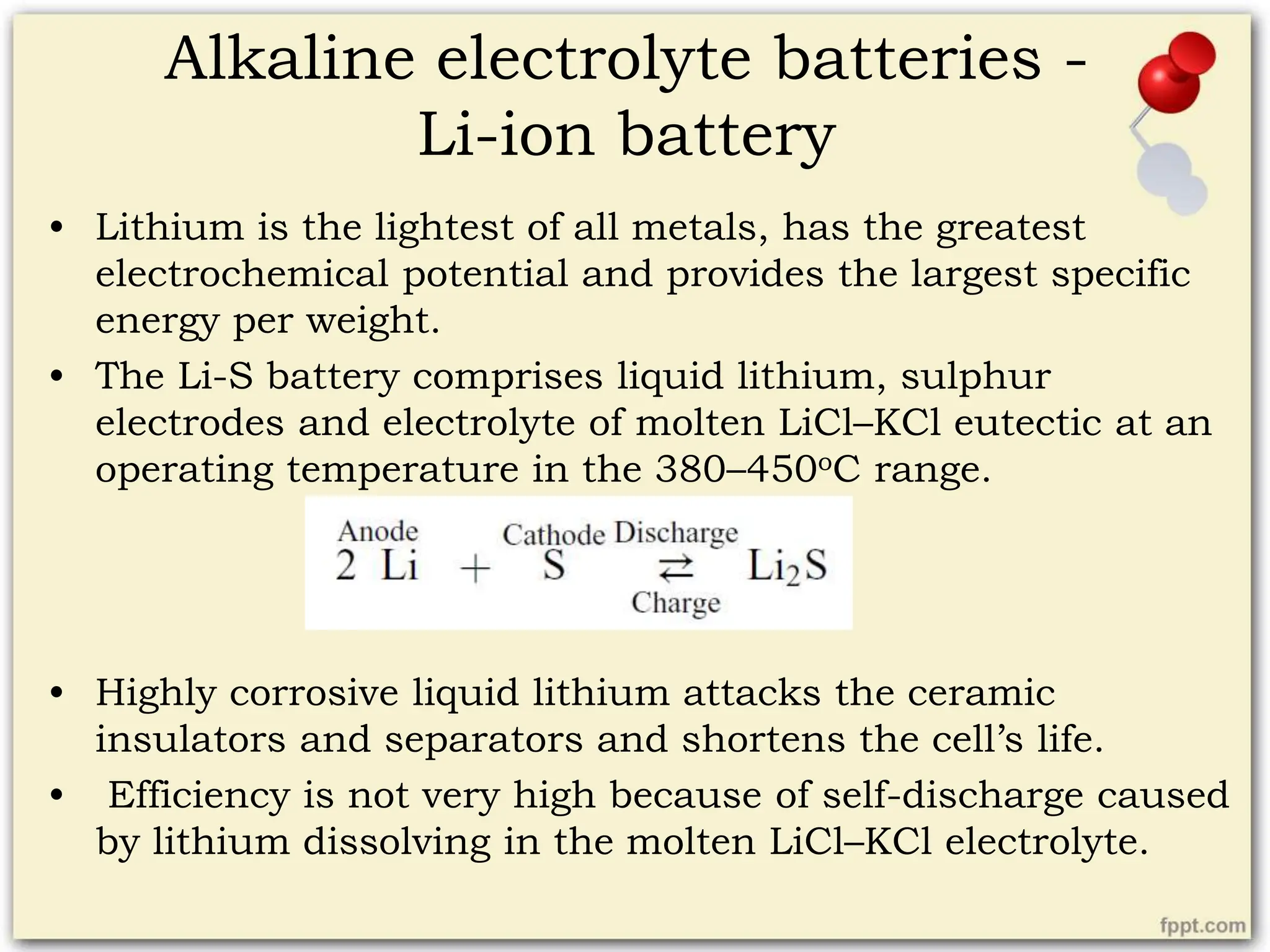

This document provides an overview of various electrochemical energy storage technologies, including primary and secondary batteries, fuel cells, and different types of batteries. It discusses the basic components and operating principles of batteries, including different battery chemistries like lead-acid, nickel-zinc, nickel-iron, and lithium-ion. It also covers flow battery technologies, specifically vanadium redox, zinc-bromine, and polysulfide-bromide flow batteries, explaining their components and redox reactions. Finally, it provides a brief definition of fuel cells.