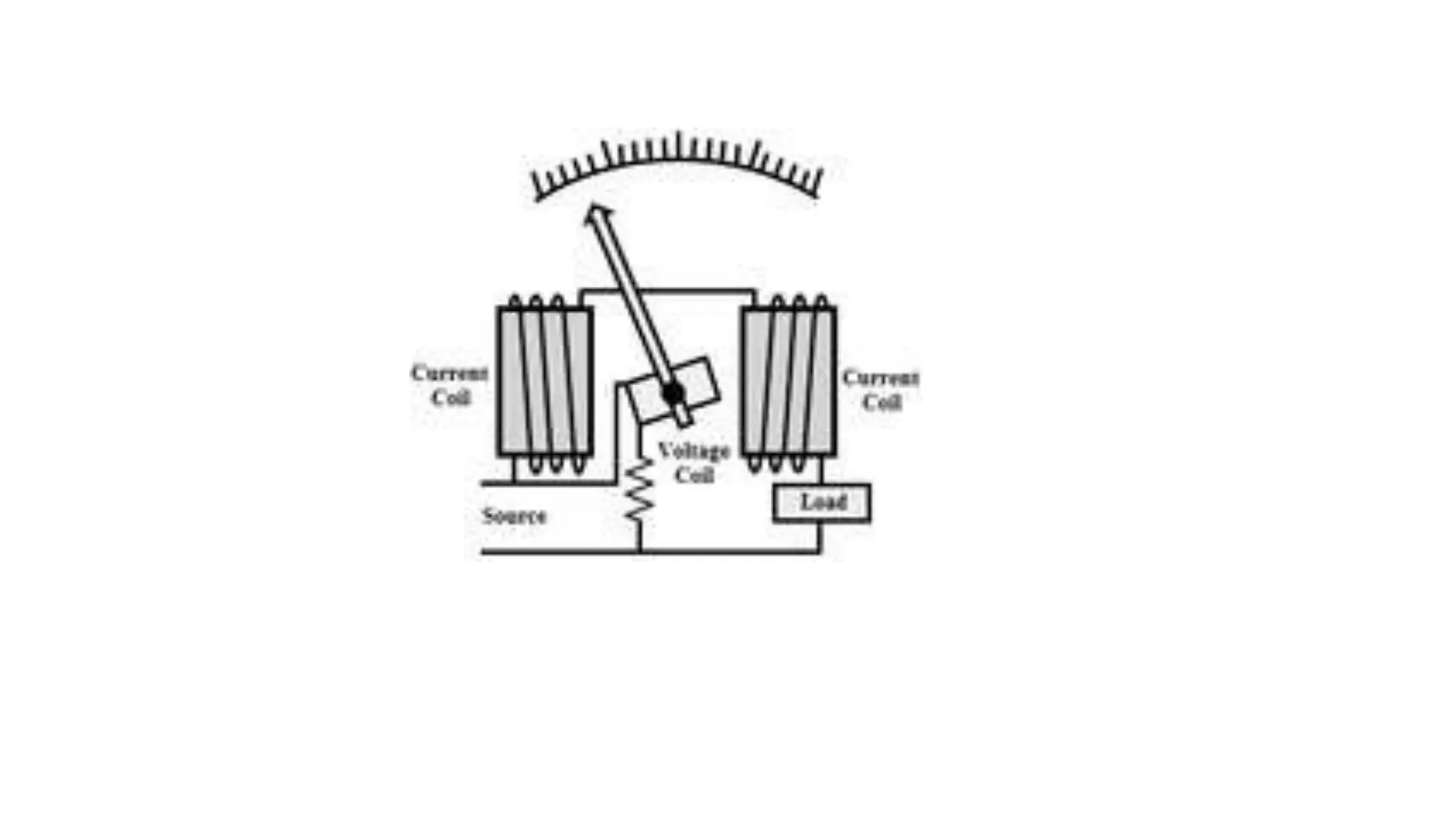

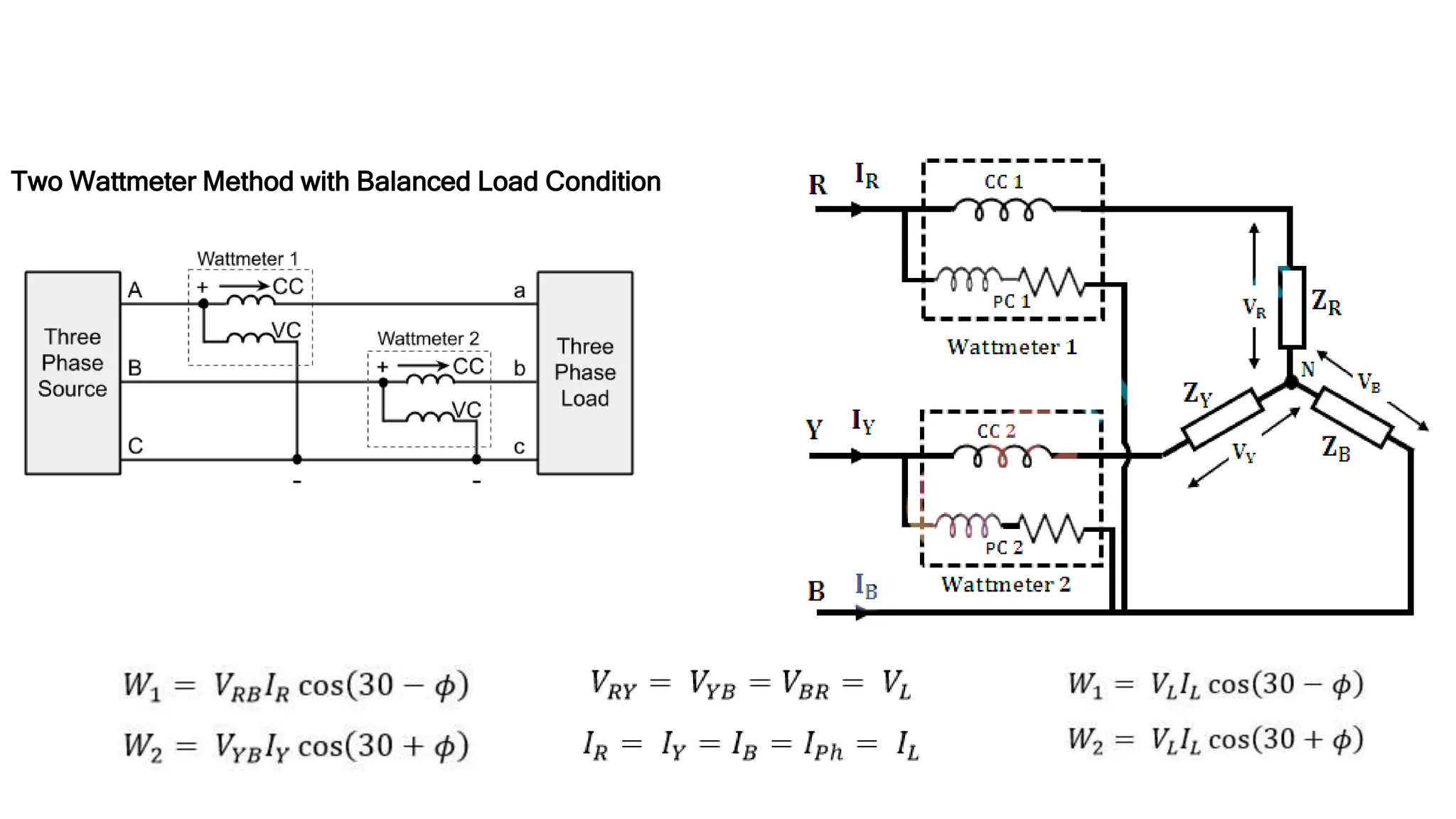

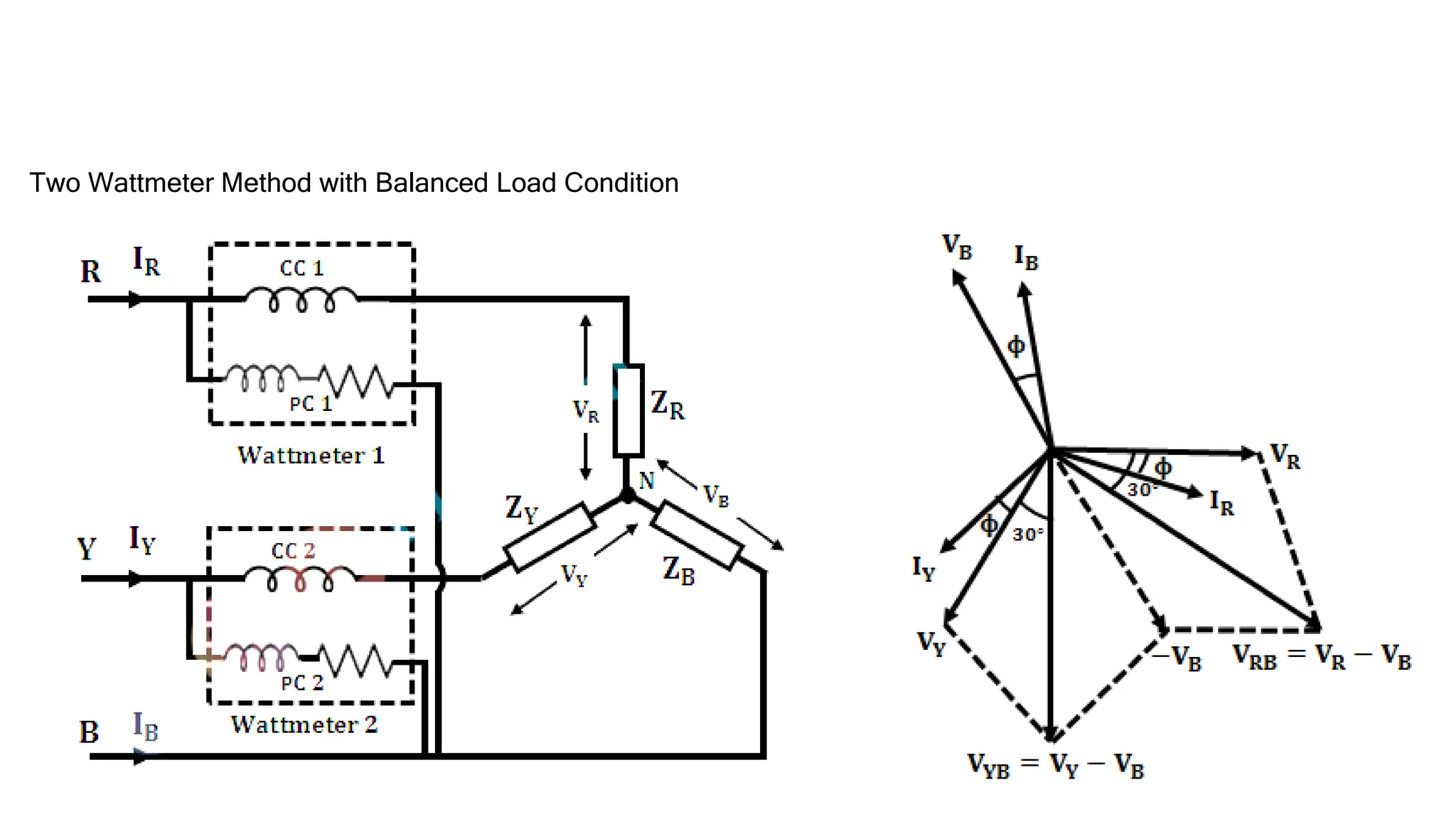

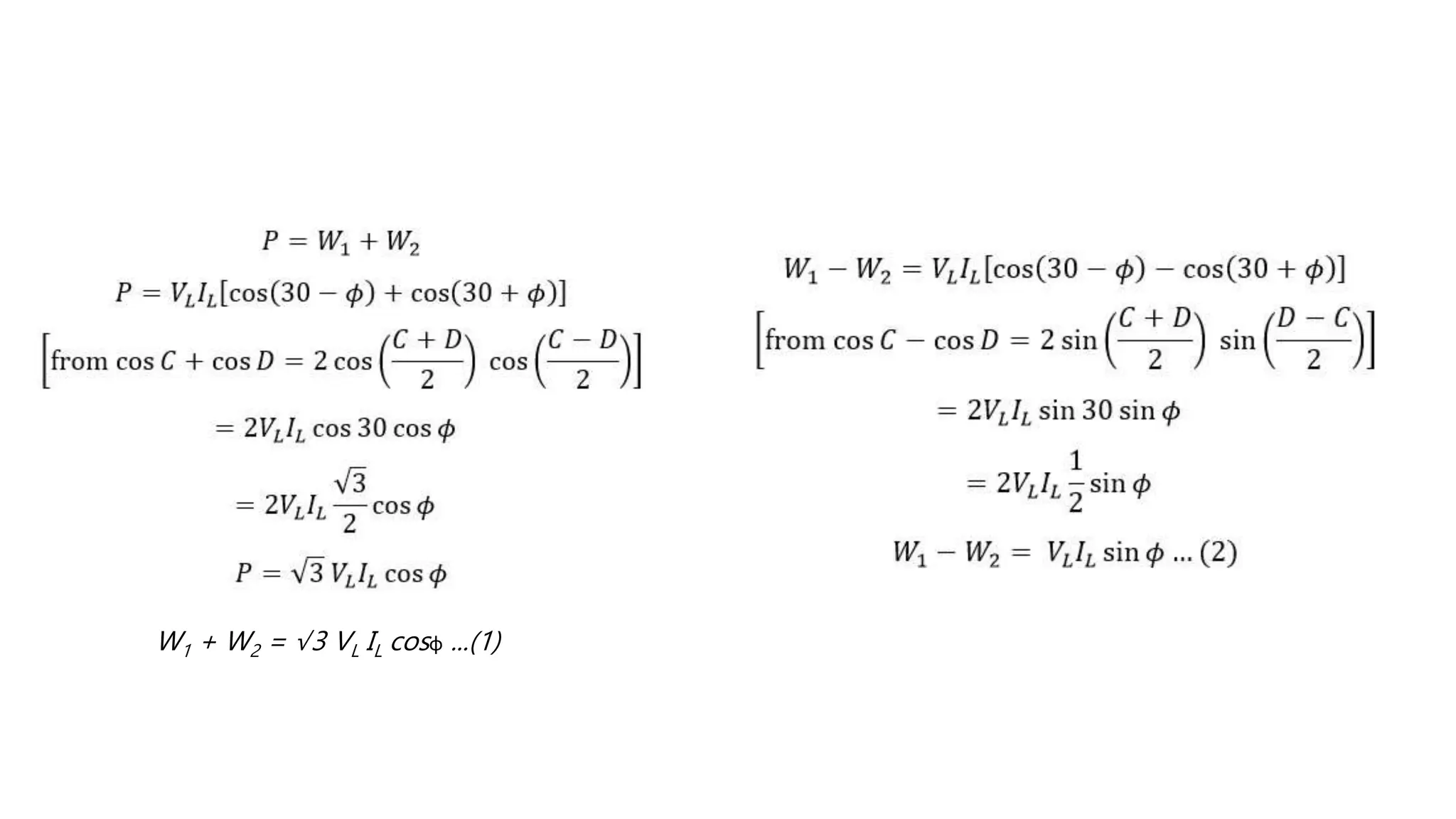

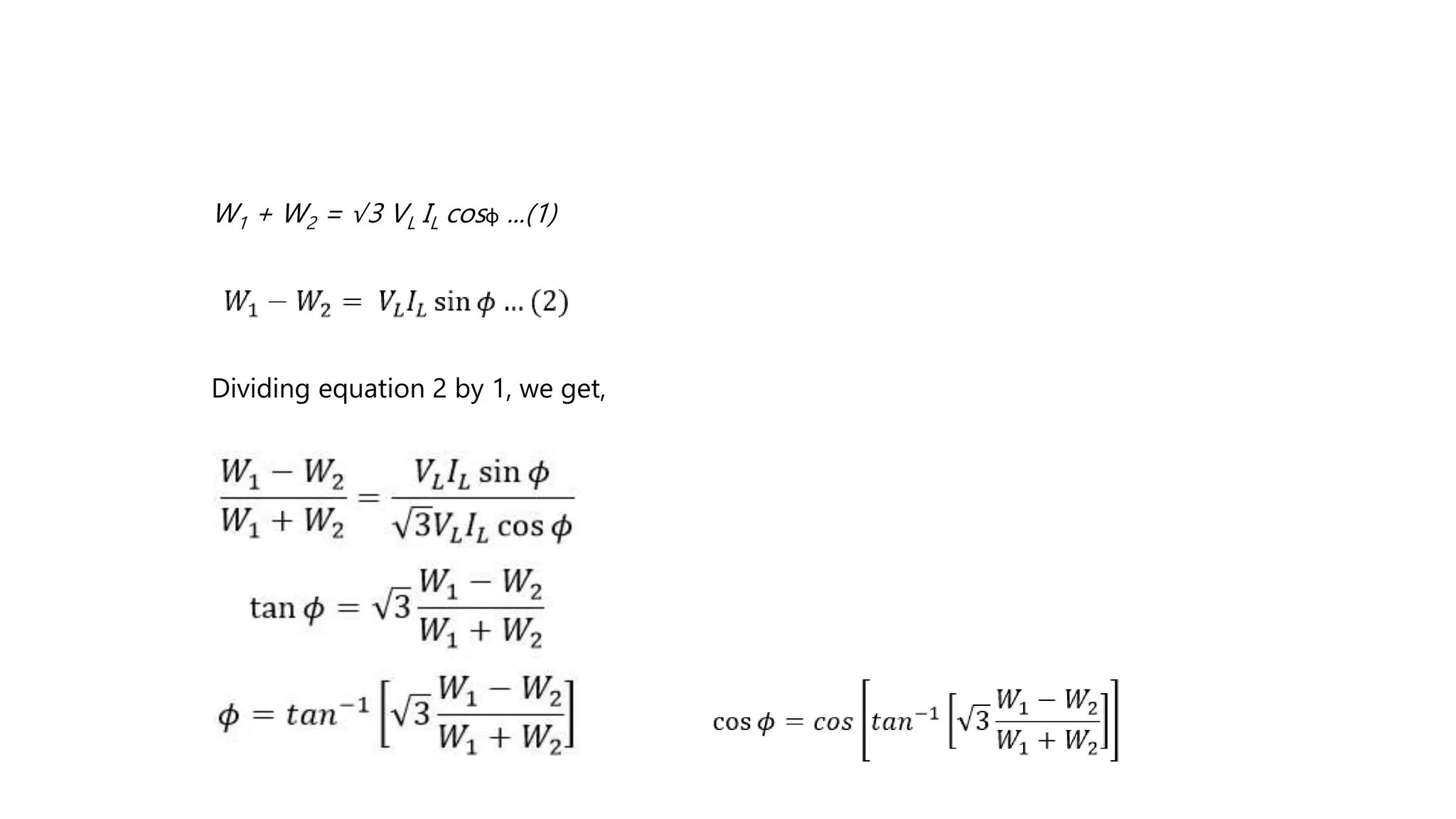

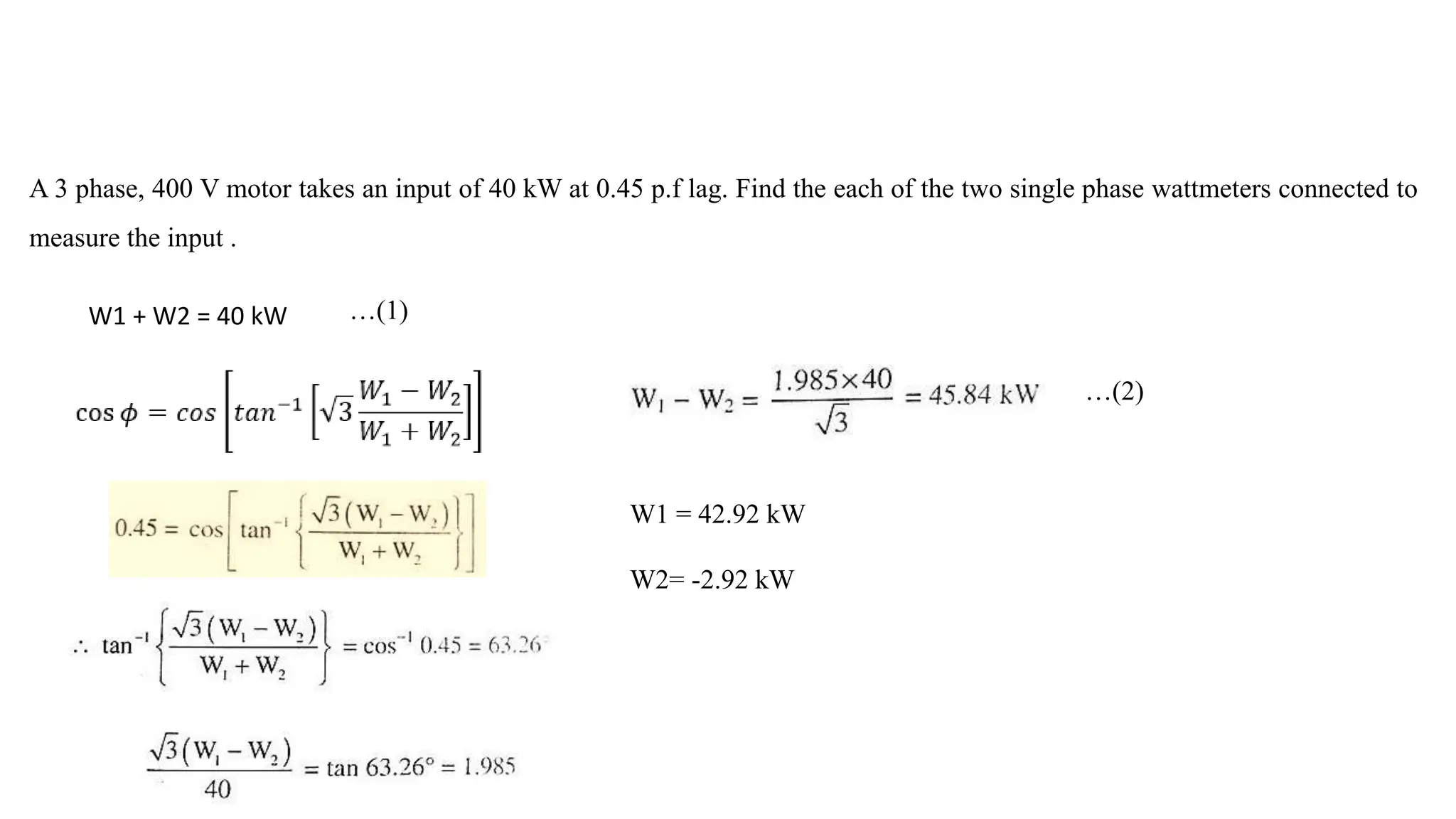

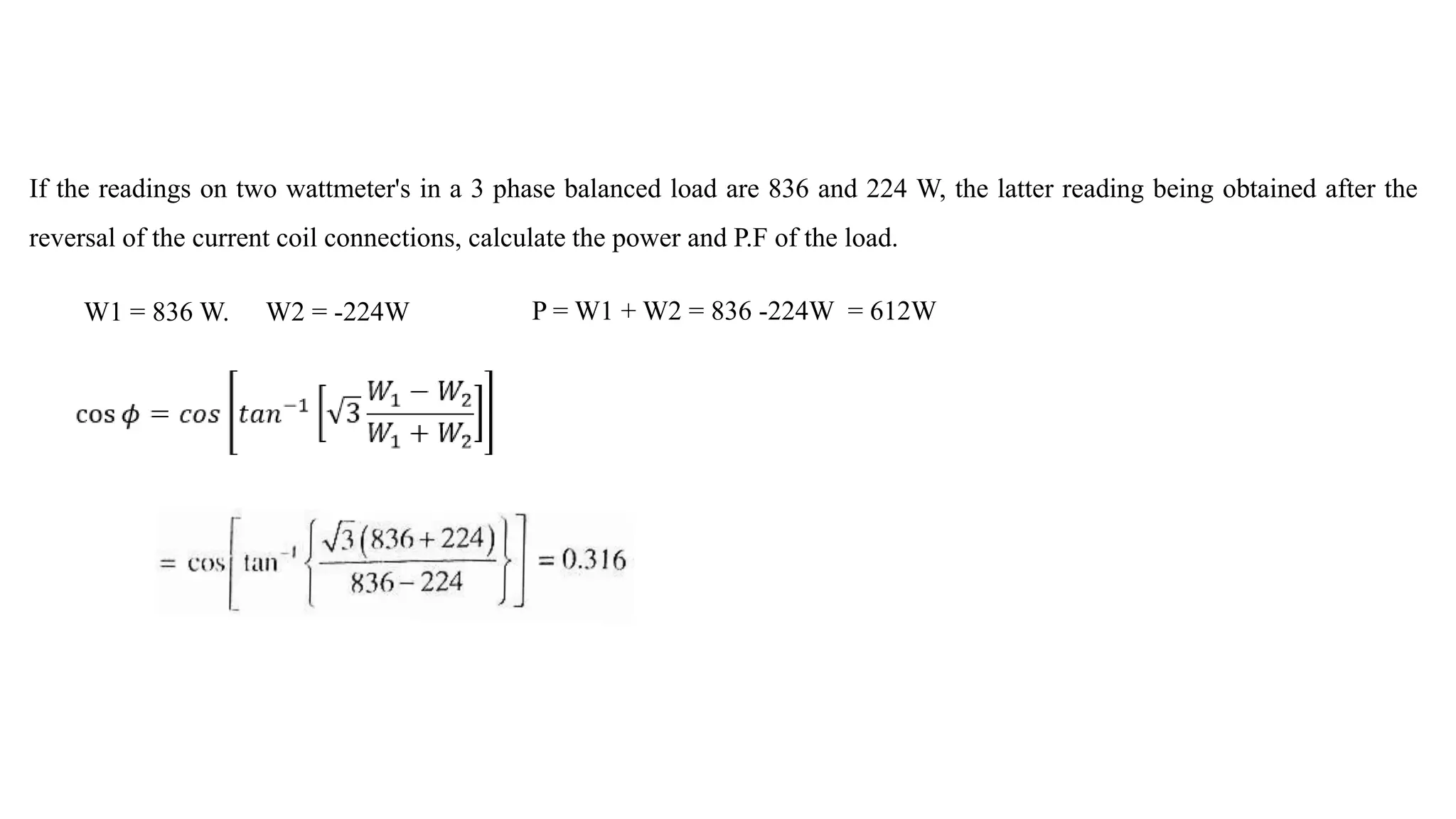

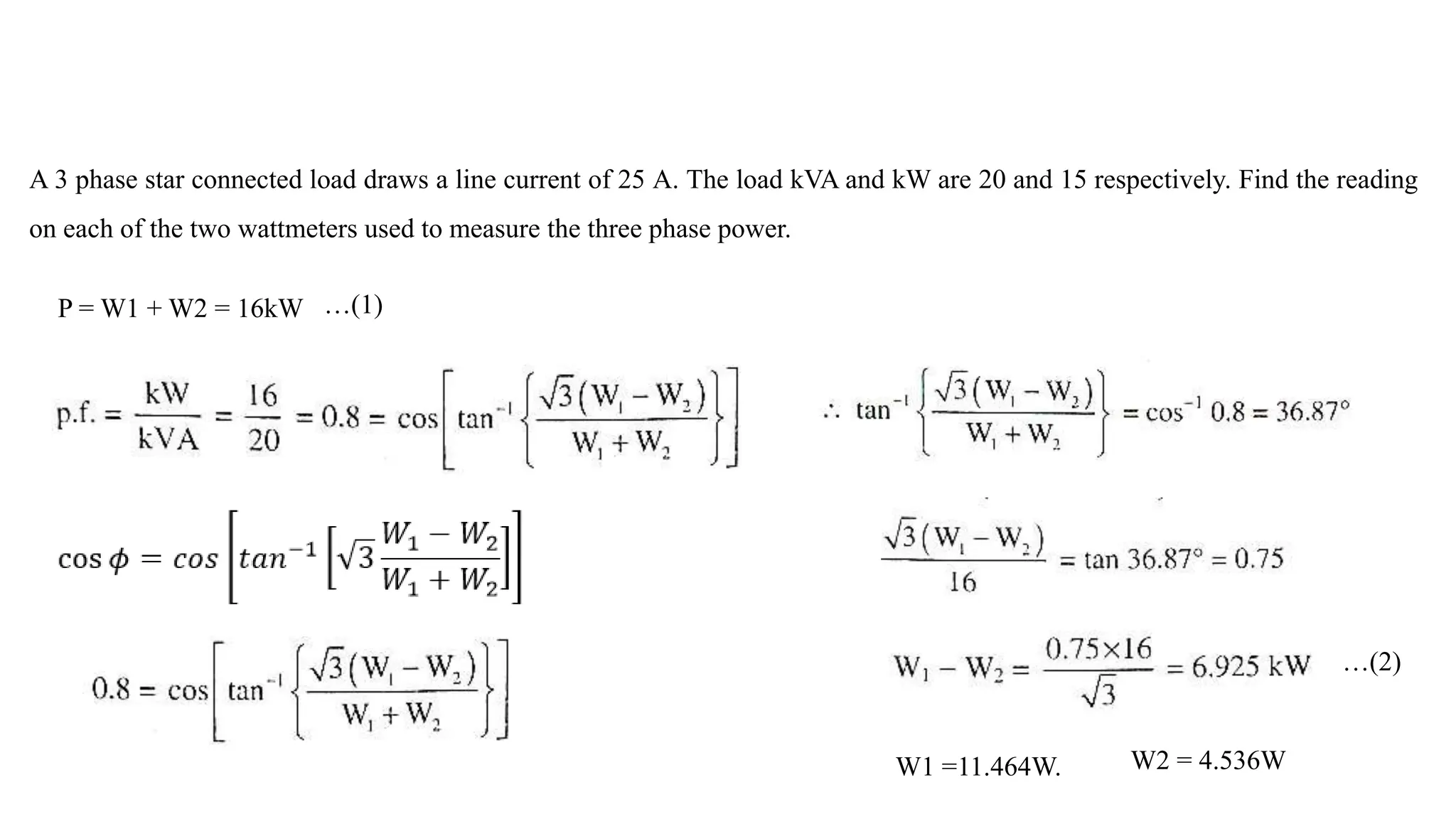

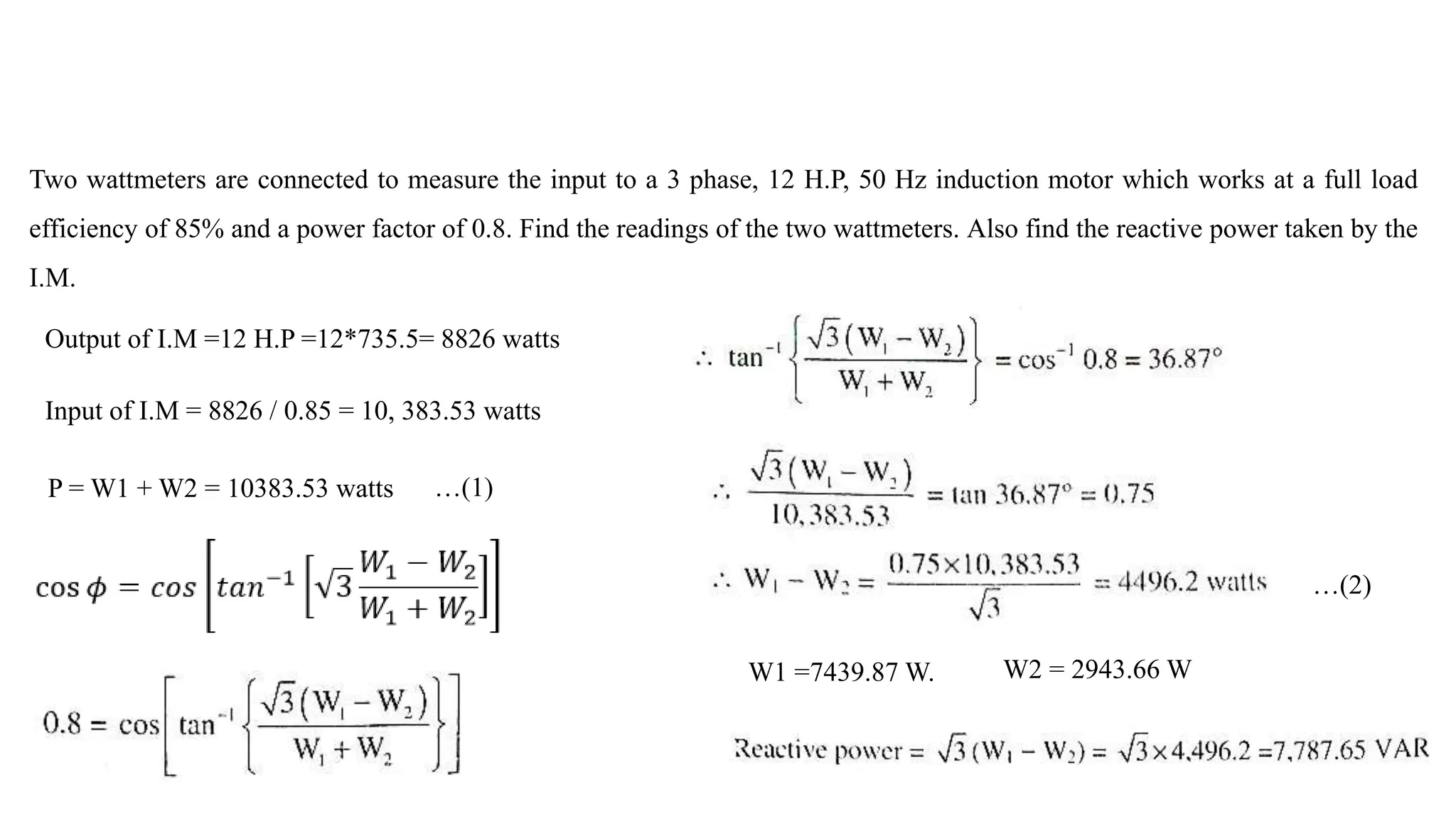

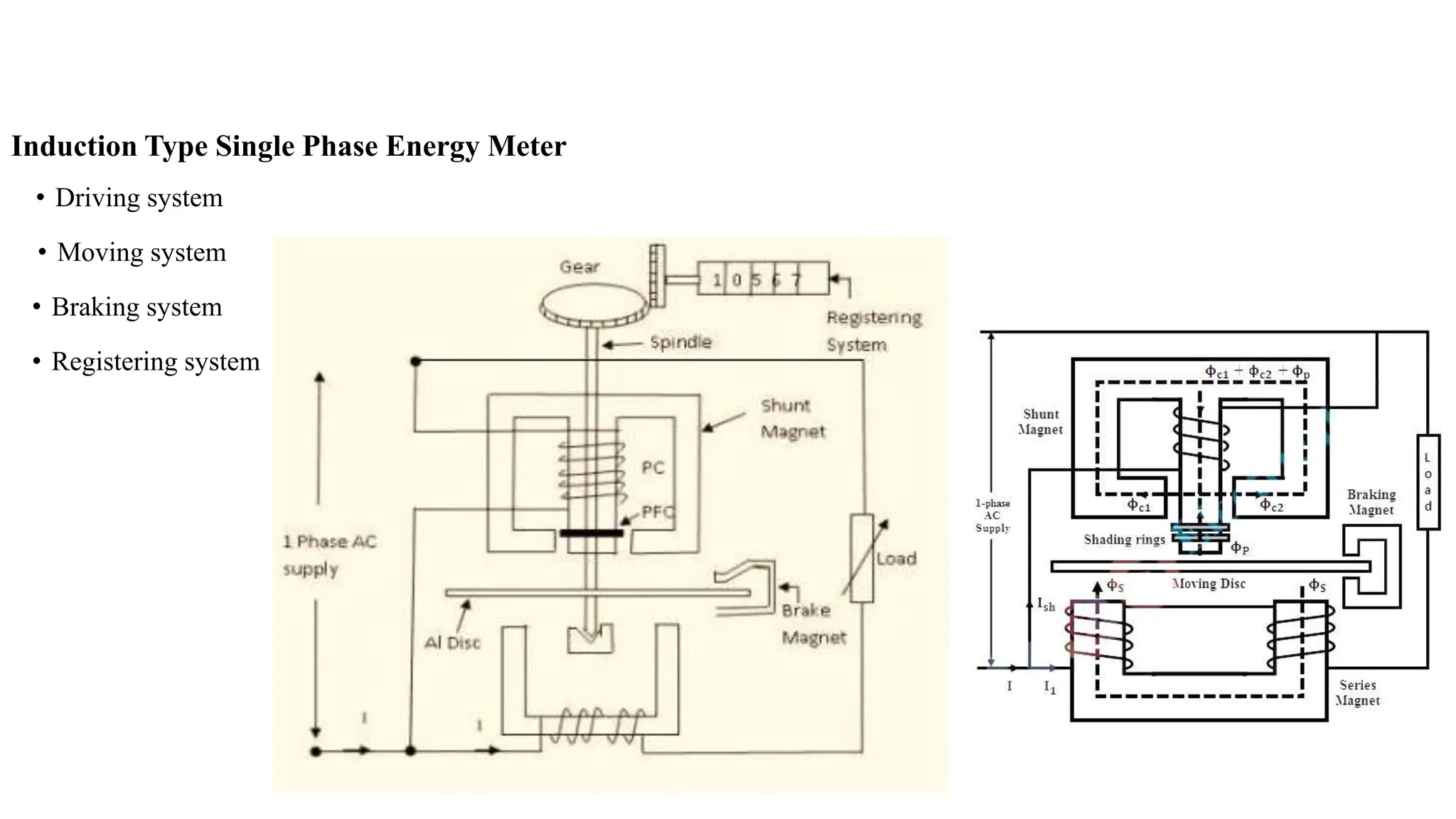

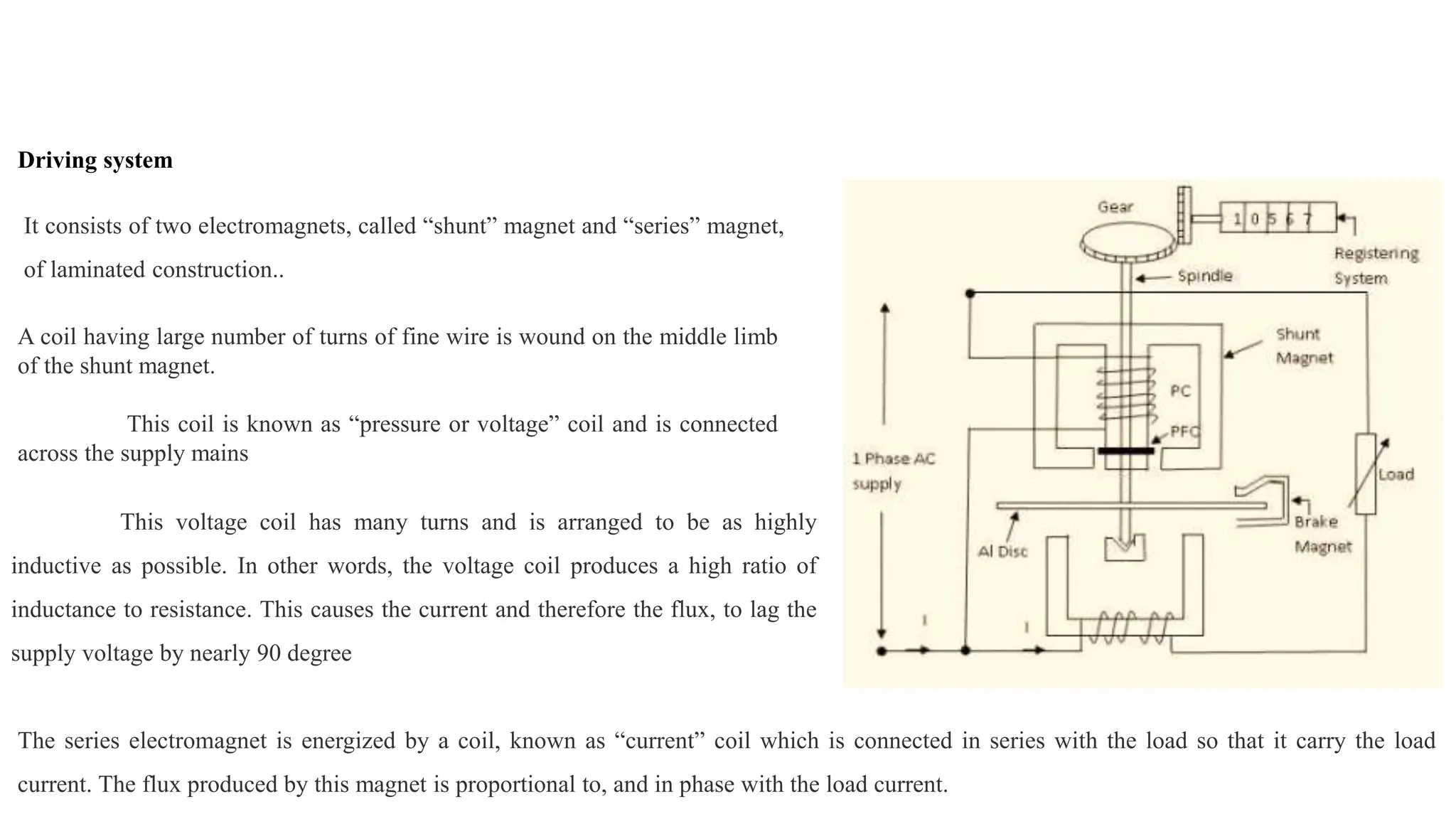

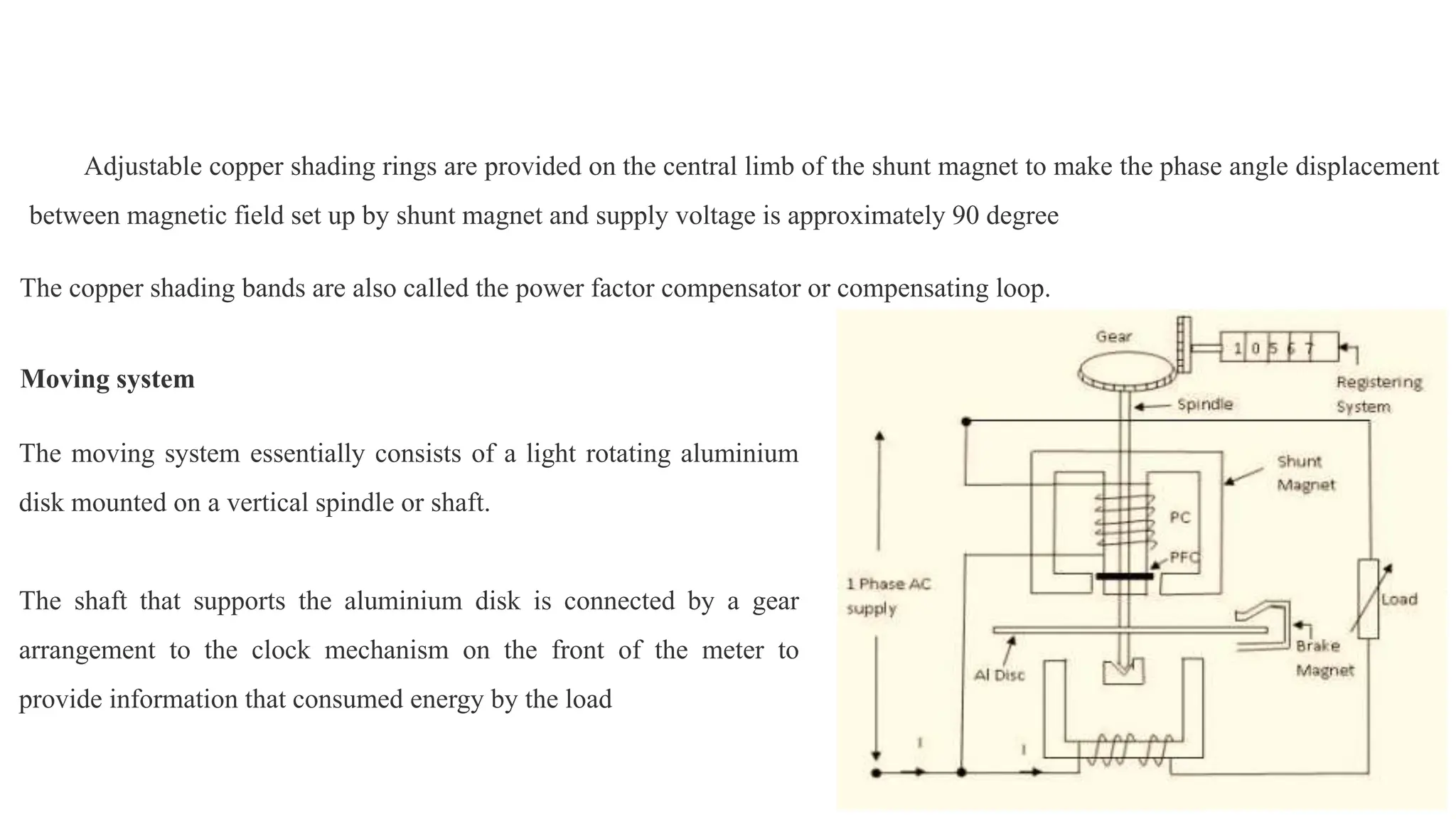

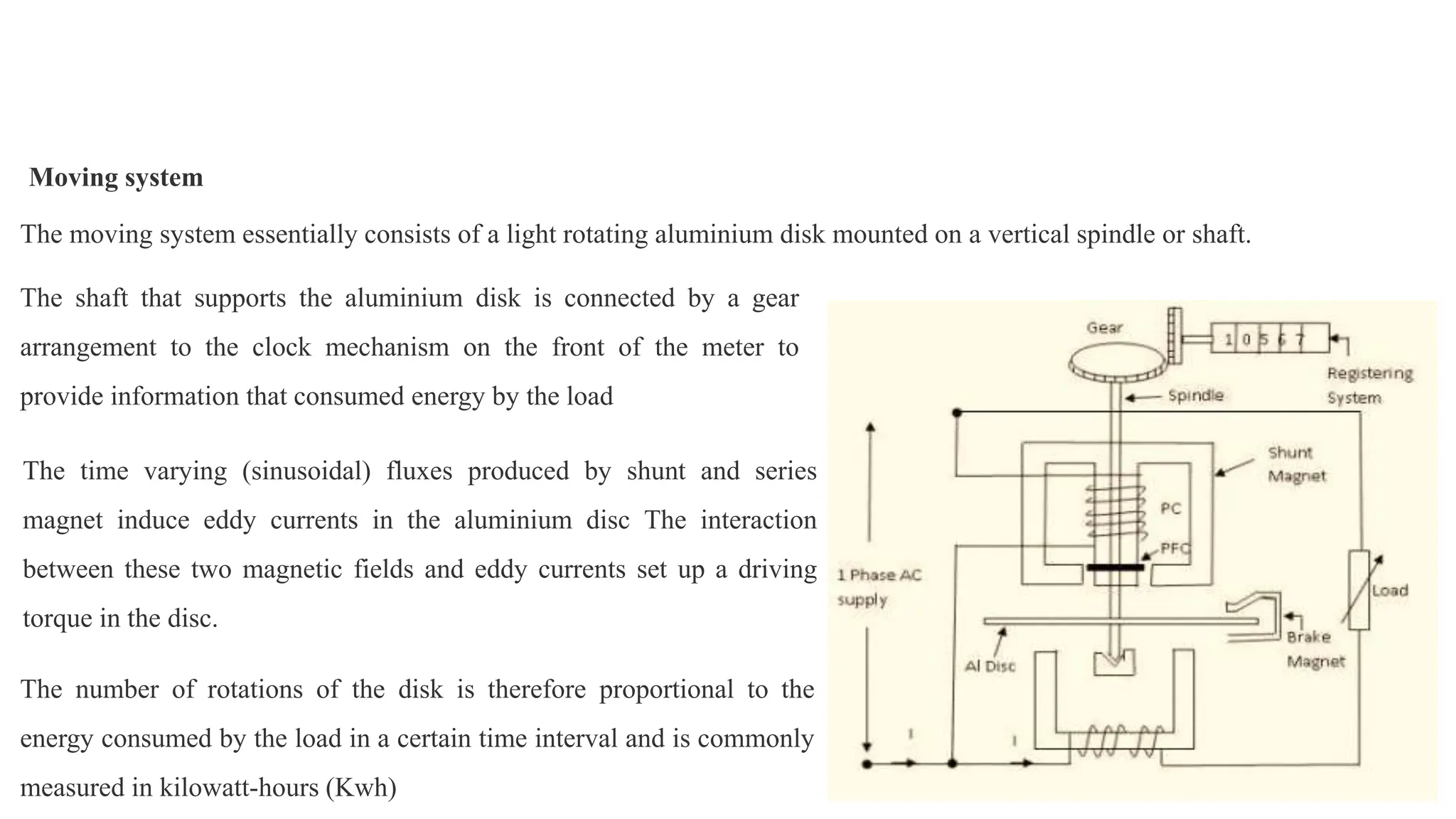

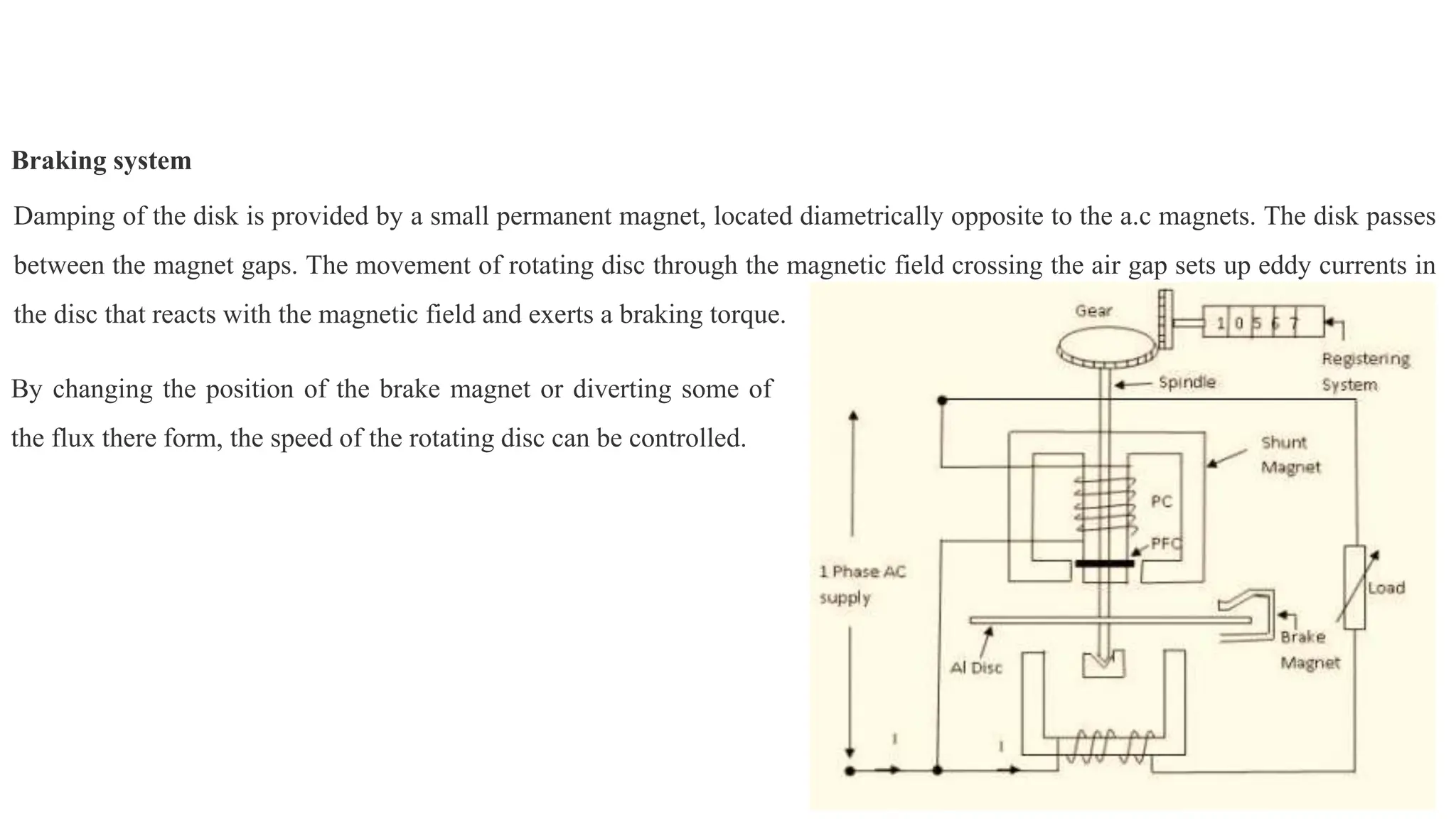

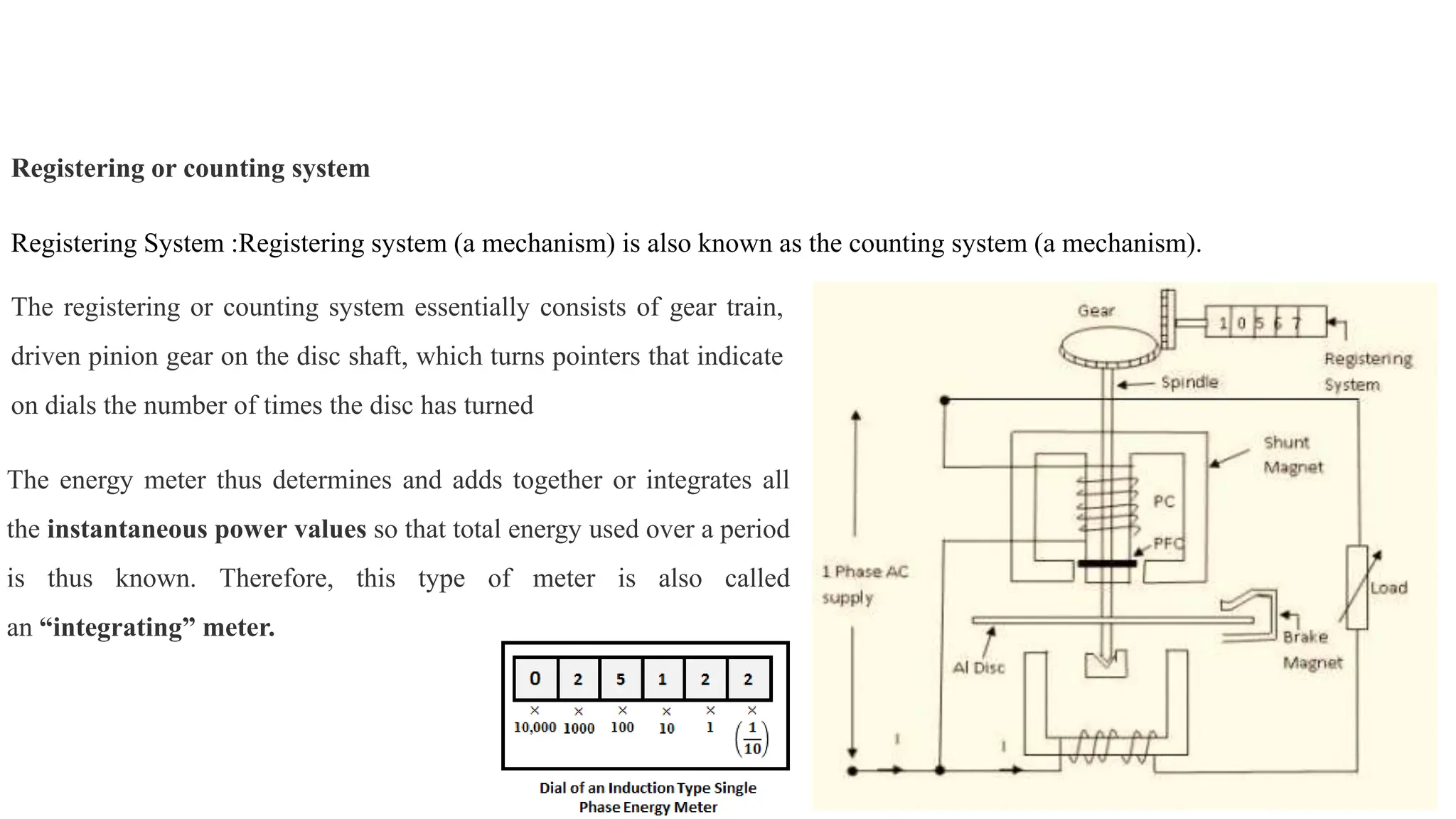

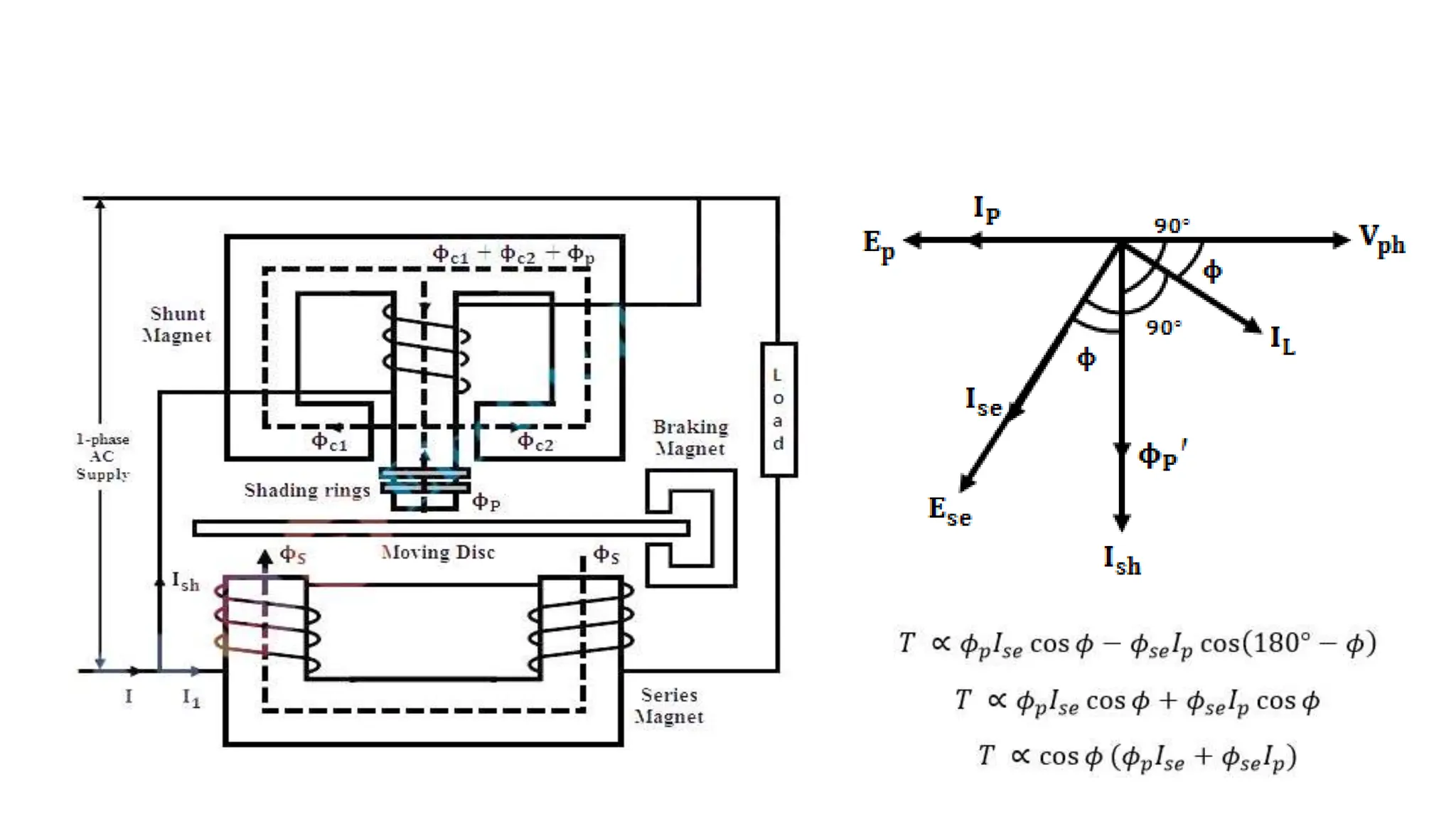

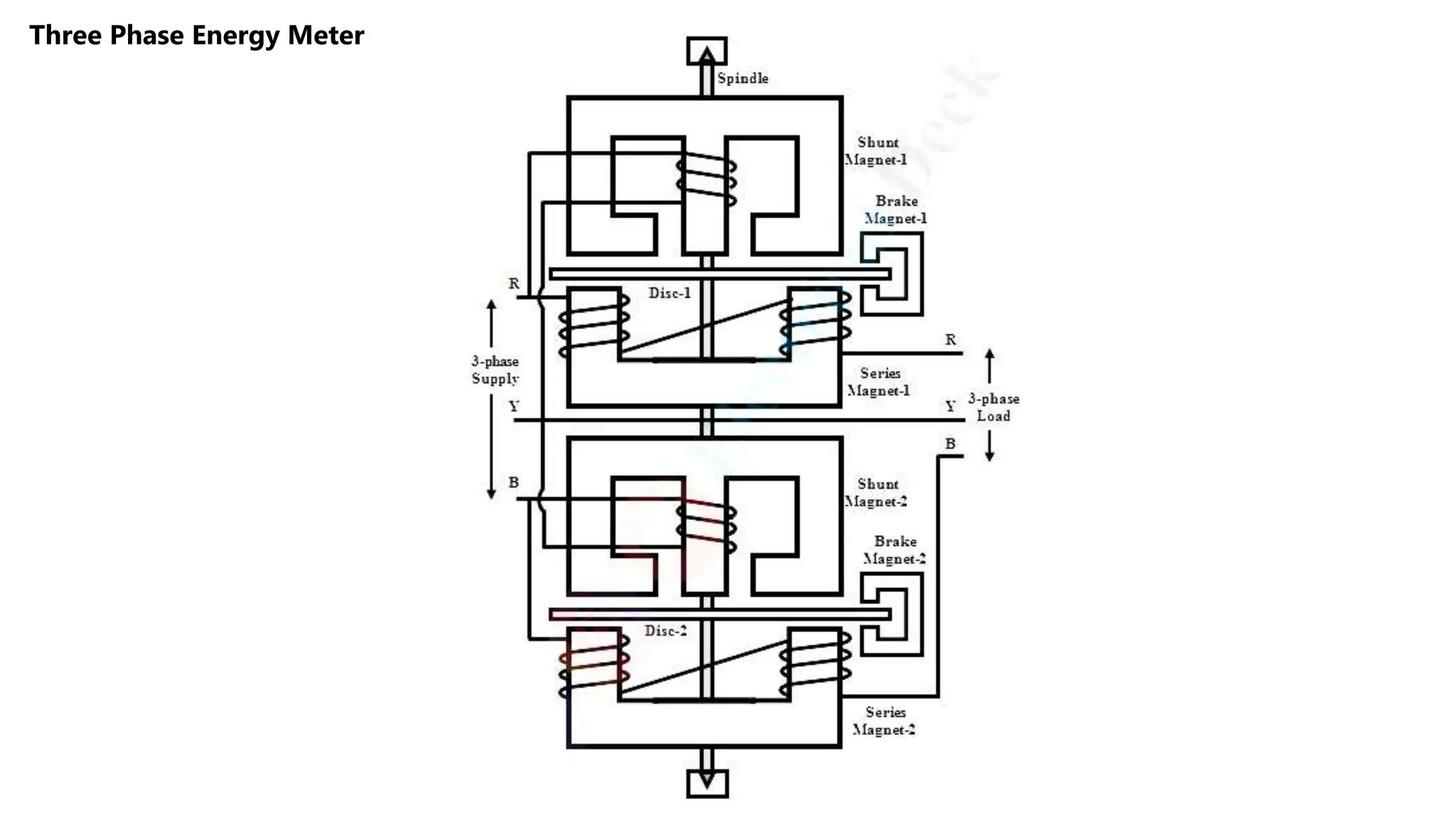

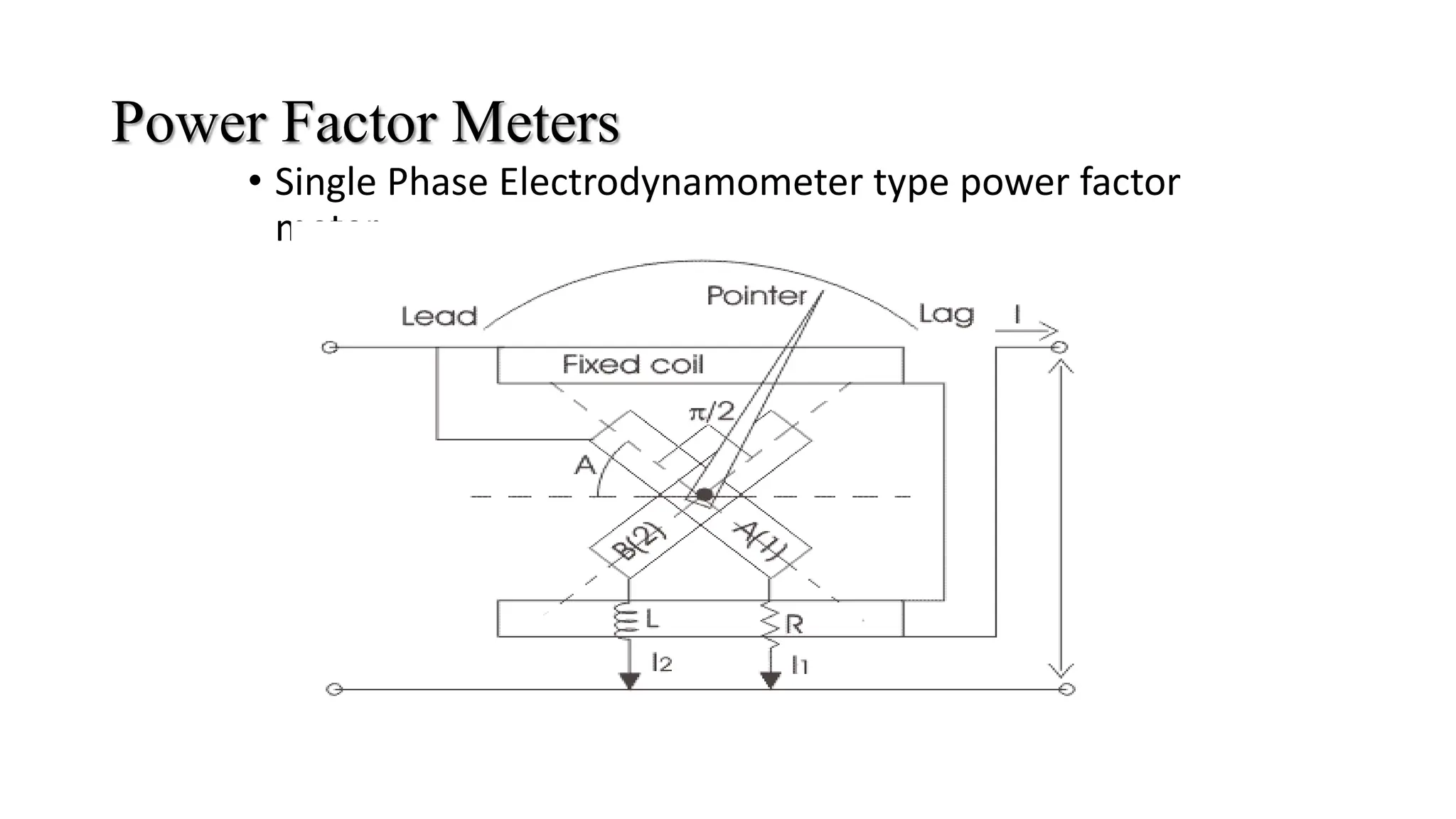

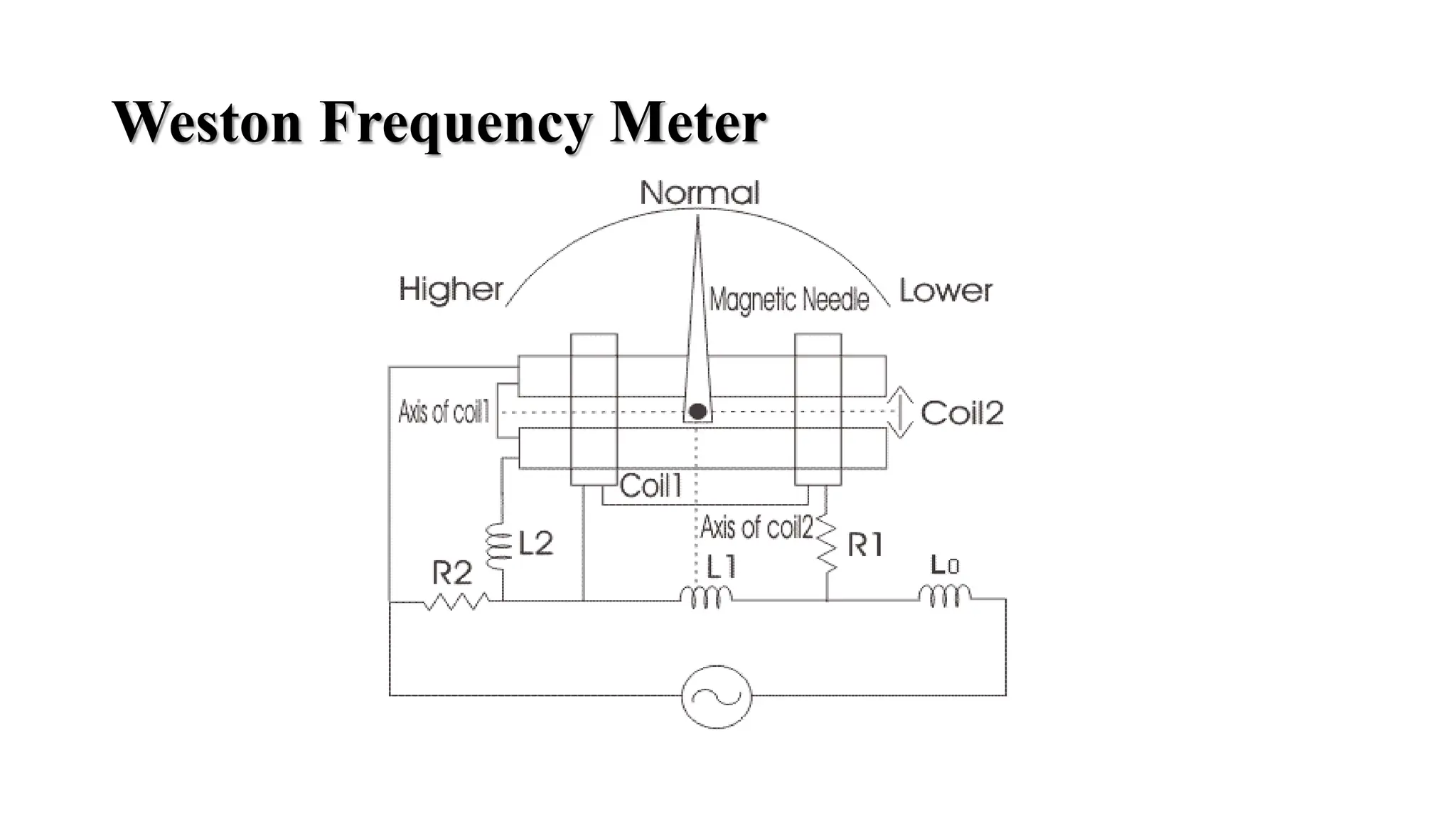

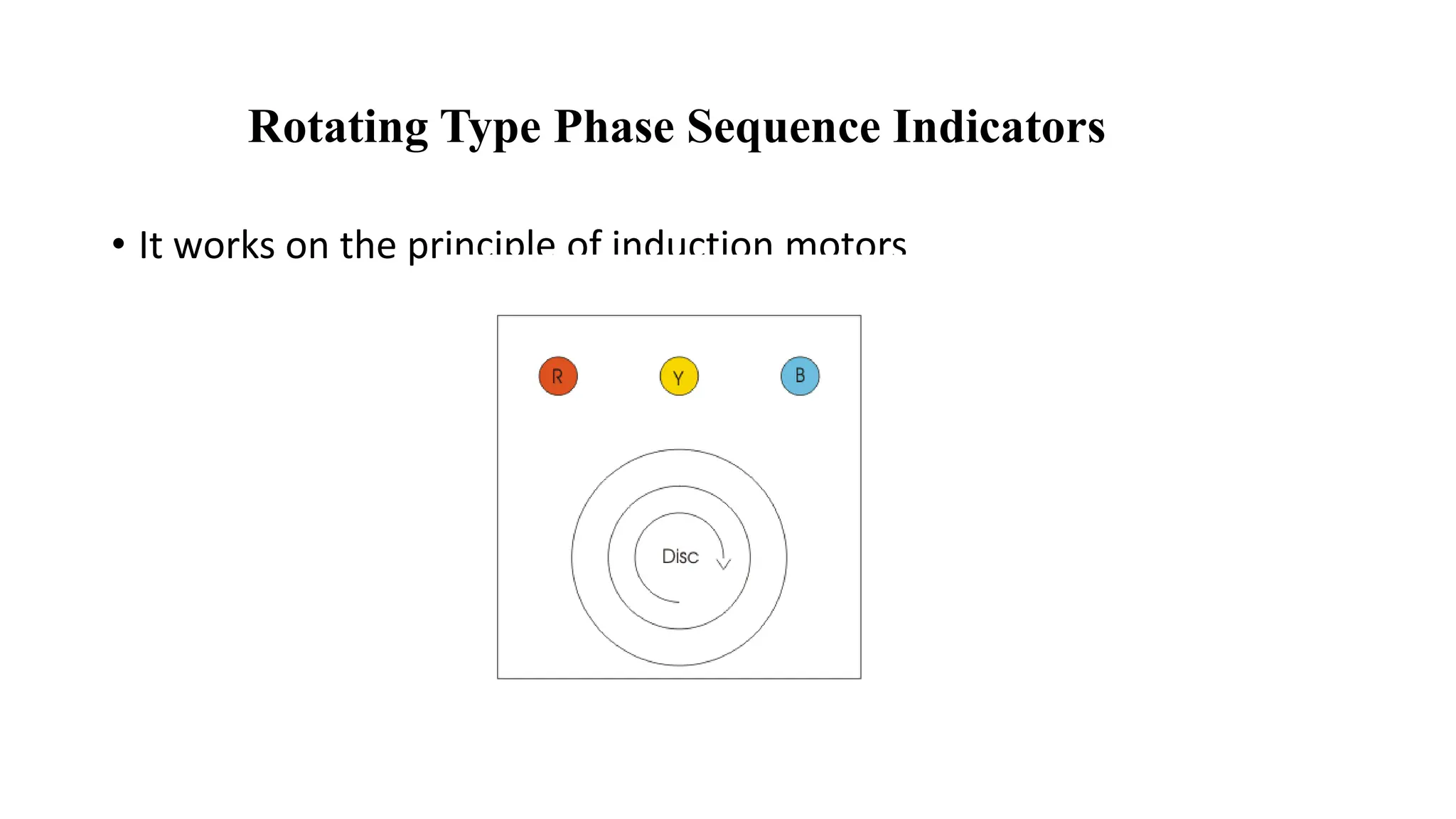

The document discusses the measurement of power factor, frequency, and phase using the two wattmeter method under balanced load conditions, providing calculations for various scenarios involving three-phase motors and energy meters. It describes the components and functioning of both single-phase and three-phase energy meters, including driving, moving, braking, and registering systems. Additionally, it covers the principles of power factor meters and phase sequence indicators.