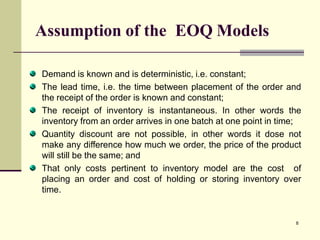

This document discusses economic order quantity (EOQ) models for inventory management. It defines EOQ as the order quantity that minimizes total annual inventory costs, including ordering costs and carrying costs. It presents the mathematical formula for calculating EOQ as the square root of 2 times annual demand times ordering cost divided by carrying cost per unit. The document also describes the 'Q' model, where a fixed quantity is ordered when inventory reaches a reorder point, and the 'P' model, where inventory is reviewed and ordered periodically. It notes the merits of each model in reducing costs and the demerits like inflexibility or irregular supplier interactions.