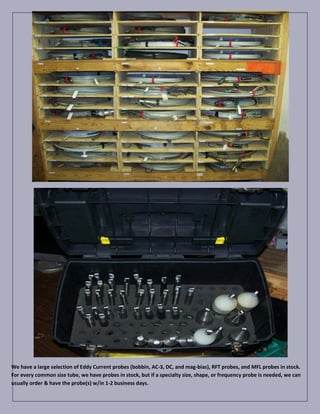

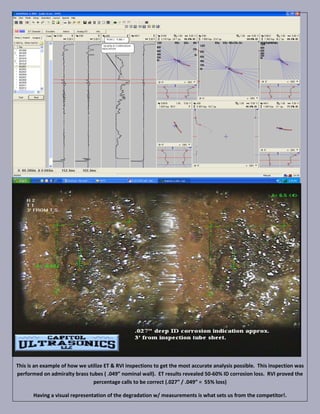

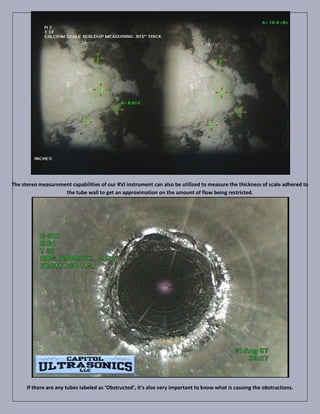

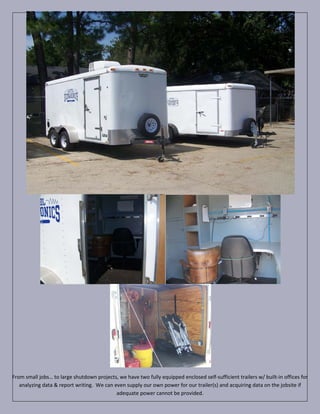

The document provides information about tubular testing services offered by a company located at 3045 Choctaw Dr., P.O. Box 53248, Baton Rouge, LA 70892. The company performs eddy current, remote field, IRIS, and magnetic flux leakage testing of tubular structures using RD Tech MS5800 instruments. They have a large stock of probes and standards for various tube sizes and materials. The company uses video probes to provide visual representations of any findings to customers.